19

www.evolutionpowertools.com

EN

• Ensure that the blade and blade flanges are clean and free

from any contamination.

• The inner-blade flange should be left in place but if it is

removed for cleaning it must be replaced the same way

round as it was removed from the machine.

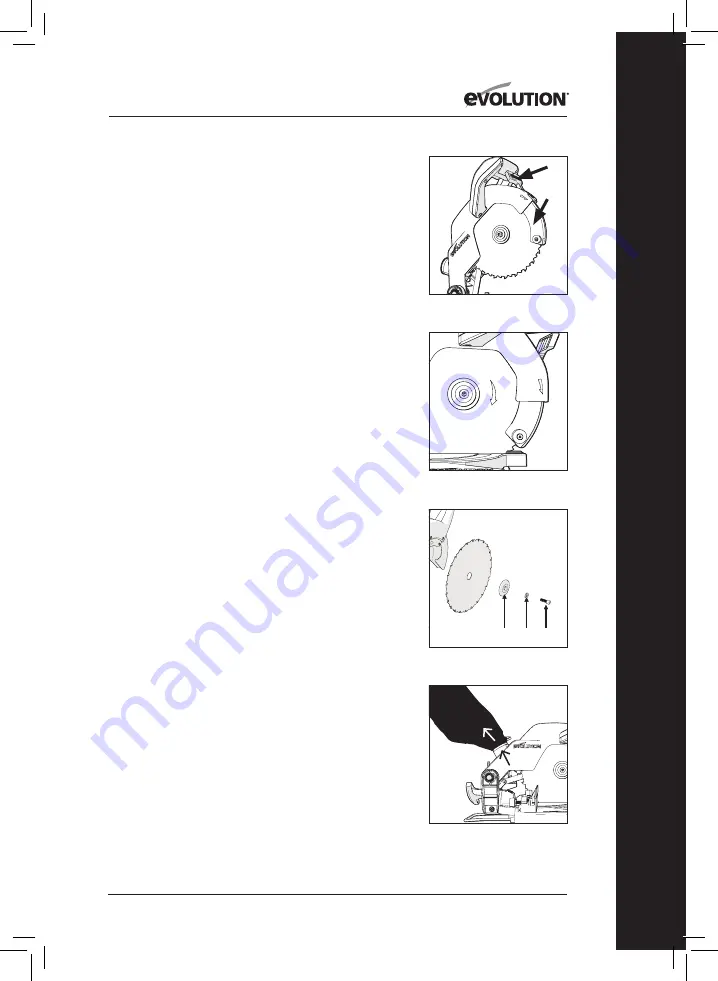

To insert the blade press the lower blade guard release trigger

(A)

rotate the lower blade guard

(B)

up into the upper blade

guard and hold the lower blade guard in that position

(Fig. 28)

.

Install the new blade onto the inner flange ensuring it is seated

properly on the flange shoulder and then slowly release the

lower blade guard back to its original closed position.

Make sure the rotation arrow on the blade

(A)

matches the

clockwise rotation arrow on the upper guard

(B)

(Fig. 29)

.

Note:

The blade teeth should always point downward at the

front of the saw.

Install the outer flange

(1)

(flat face onto the machine),

washer

(2)

and arbor screw

(3)

(Fig. 30)

.

Press & keep pressing the arbor lock button on the motor

housing while tightening the arbor screw using the supplied

hex key until the button locates fully into the shaft and locks

the shaft

(Fig. 26)

.

Tighten the arbor screw using moderate force, but do not

overtighten. Ensure the hex key is removed and the arbor lock

button has released before operating. Ensure the blade guard

is fully functional before using the machine.

(8.12)

USE OF OPTIONAL EVOLUTION ACCESSORIES

Not supplied as original equipment

(see ‘

Additional Accessories’

)

.

(8.13)

DUST BAG

A dust bag can be fitted to the extraction port at the rear of

the machine. The dust bag is for use when cutting wooden

materials only.

• Slide the dust bag over the dust extraction port,

ensuring that the spring clip grips the port holding

the dust bag securely in place

(Fig. 31)

.

Note:

For operational efficiency empty the dust bag when

it becomes 2/3 full. Dispose of the contents of the dust bag

in an environmentally responsible way. It may be necessary

to wear a dust mask when emptying the dust bag.

Note:

A workshop vacuum extraction machine can be

attached to the dust extraction port if required. Follow the

vacuum manufacturers instructions if such a machine is fitted.

WARNING:

Do not use the Dust Bag when cutting

metallic materials.

Fig. 28

Fig. 31

A

B

Fig. 29

A

B

(1)

(2)

(3)

Fig. 30

(1)

(2)

(3)