13

Take the two wing tip pieces (Part 9(2)) and glue onto the tips of the wing using foam safe Cyano or UHU

Por. The tip should be lined up with the centre of the leading edge and the centre of the trailing edge. With

some scrap 3mm (1/8”) sheeting make the triangular fillet pieces to support the wing tip. We generally only

install the supports to the upper side of the wing, but you may wish to support on both sides. Position the

fillets as set out below. The TE fillet will have to be ‘cranked’ to allow the covering to follow the wing contour

neatly.

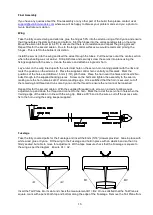

Example of cranked TE fillet

Where the tip extends past the trailing edge of the wing make a fillet with scrap 1/8” (3mm) balsa as shown

in the right-hand picture above.

Shape the leading edge roughly with a razor Plane before Finishing with shaping paper as shown in the

diagram on page 11, continually checking the fit to the Fuselage.

Shaping the entire wing to provide a smooth, blemish free surface ready for covering. !!!

Warning

. Ensure

that you are wearing an appropriate mask for shaping balsa and are in well ventilated area.!!! Check the fit

with the Fuselage as you go.

At this point if you would prefer you may cut off the front sheeting that passes over the wing and glue it onto

the wing itself. In the event of a hard landing it is more likely to allow the wing to ‘shift’. We have not done

this with the prototype models and it is left to the builder’s discretion.

Glue the 1mm (1/32”) ply doubler (Part 26) to the rear of the wing to protect the trailing edge when the rubber

bands are fitted

Ailerons

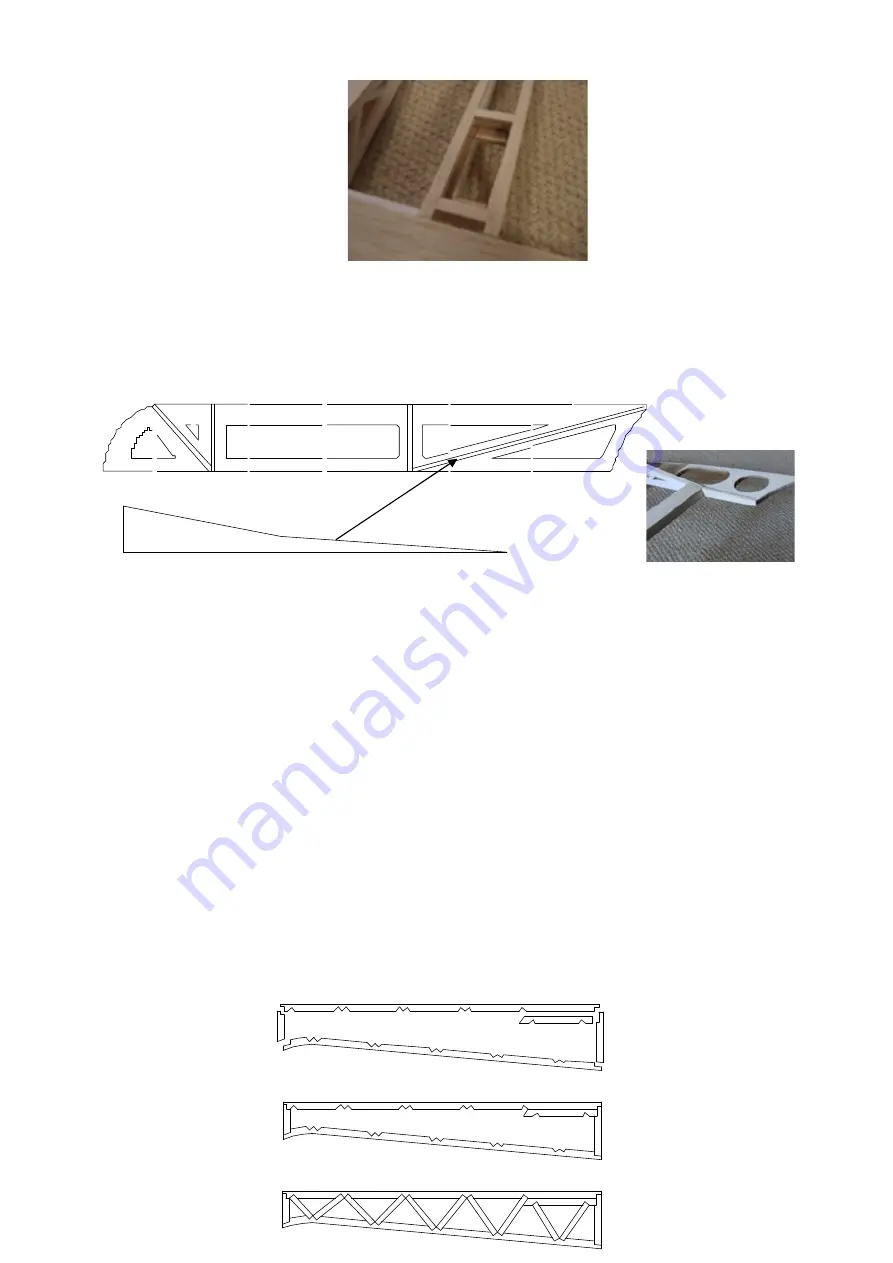

Take the five pre-cut parts (Parts 7(2), 12(2), 15(2), 16(2) and 17(2))

which form the ailerons,

trial fit, ensure

the tips are at 90° to the leading edge, fit the trailing edge, when satisfied glue with Cyano or white wood

glue. With a supplied strip of 6mm x 9.5mm x 915mm (¼” x 3/8” x 36”) cut to length to form the ten ribbing

pieces, glue in place.