14

www.evolutionpowertools.com

• Safely store the outer blade flange and associated fixings.

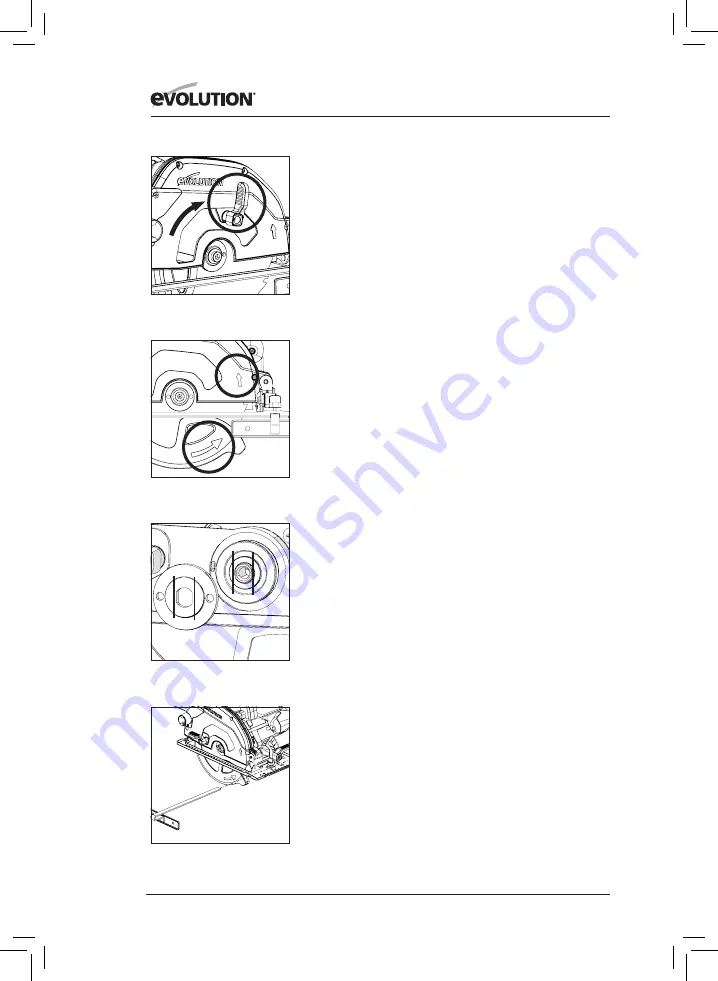

• Rotate the lower blade guard up into the upper blade guard

using the manual thumb lever.

(Fig. 5)

• Carefully remove the blade (if fitted) from the machine.

• Thoroughly clean inner and outer blade drive flanges.

Note: The inner blade flange can be left in place if desired, but

it should be checked and thoroughly cleaned. If it is removed

from the machine it must be replaced back in the same

orientation as it was before removal.

• Thoroughly clean the blade around the bore area (both

surfaces) where the blade flanges will touch and clamp

the blade.

• Install the (new) blade.

• Ensure that the direction of rotation arrows printed on the

blade, match the direction of rotation arrows found on the

machines upper and lower blade guards.

(Fig. 6)

• Reinstall the outer drive flange, the socket headed arbor

screw, and its associated fixings.

Note: The outer drive flange has a specially machined bore

which incorporates two opposed ‘flats.’

(Fig. 7)

These ‘flats’

engage with two complimentary ‘flats’ machined into the

machines arbor shaft.

• Re-engage the arbor lock and tighten the arbor socket

headed screw securely using the Hex Key.

• Release the arbor lock button

• Return the Hex Key to its dedicated storage position.

• Check that the arbor lock has fully released by manually

rotating the blade.

• Check the operation of the lower blade guard.

(11)

PARALLEL EDGE GUIDE

A Parallel Edge Guide

(Fig. 8)

which can be particularly helpful

when rip cutting, is supplied with these machines.

The guides arm should be inserted through the rectangular

slots positioned at either side (front) of the sole plate, and slid

under the centrally located adjustment locking screw.

(Fig. 9)

Note:

The Parallel Edge Guide can be fitted on either side of the

sole plate.

WARNING:

Only fit and adjust the Guide with the machine

disconnected from the power supply.

Note:

The arm of the Parallel Edge Guide must pass through all

of the rectangular slots provided in the sole plate.

WARNING:

It is potentially dangerous to install, and try to use

Fig. 5

Fig. 6

Fig. 7

Fig. 8