11

Operation

WARNING! Before commissioning must check the oil level in the compressor.

WARNING! IN case of any abnormal noise, immediately turn off the tool and

contact an authorized service facility for repairs

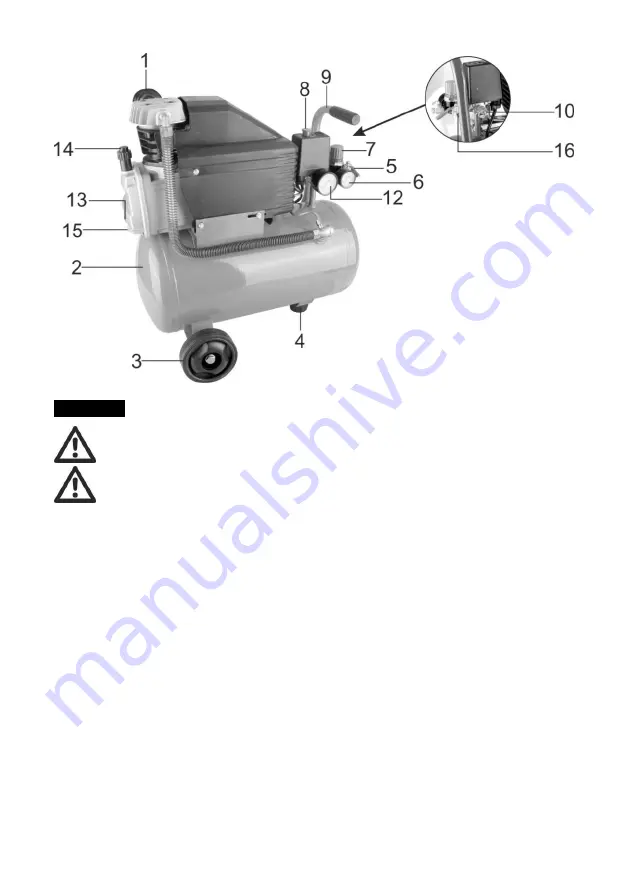

Asembly and components checking

Install wheels (3) and foot (4)

– with bolts and nuts provided

Replacing the air filter (1) - Remove the brackets used during transport with a screwdriver or

similar tool and attach an air filter (1) by screwing on the device. (Fig. 7)

Changing the oil cap closure (14) - Remove the transport cover from the oil filler hole using a

screwdriver and place the cap closure (14) in the spout (Fig. 8).

The compressor is equipped with power-connection cable with protective contact plug. It can

be plugged into any socket with protective contact 230V ~ 50Hz which is equipped with a

safety 16 A. Before starting, check whether the mains voltage corresponds to the operating

voltage stated on the data plate device. Power cords and extension cords or long cable

drums causes low voltage and prevent proper starting.

Safety valve (10) is adjusted to the maximum allowable pressure of the pressure tank. Do not

modify or remove safety valve seal. To function properly in the event of switch damage,

safety valve should be checked weekly. Firmly pull ring out until the compressed air comes

out. Then release safety valve the valve again.

Check oil level: place the compressor on a flat,horizontal surface. The oil level should be

between MAX and MIN values of the viewfinder.

Start / stop

the operation. Compressor start by pulling out the button (8).

To switch off , the button (8) must be pressed down. (Fig. 2)