9

•

Perform a no-loading test and check:

o

The flexibility of up/down operating switch

o

The flexibility of up limit bracket

o

The flexibility of down limit bracket to make sure the cut-off circuit when the steel

cable is nearly used up.

o

Any abnormal sounds when start-up operation

Before each use

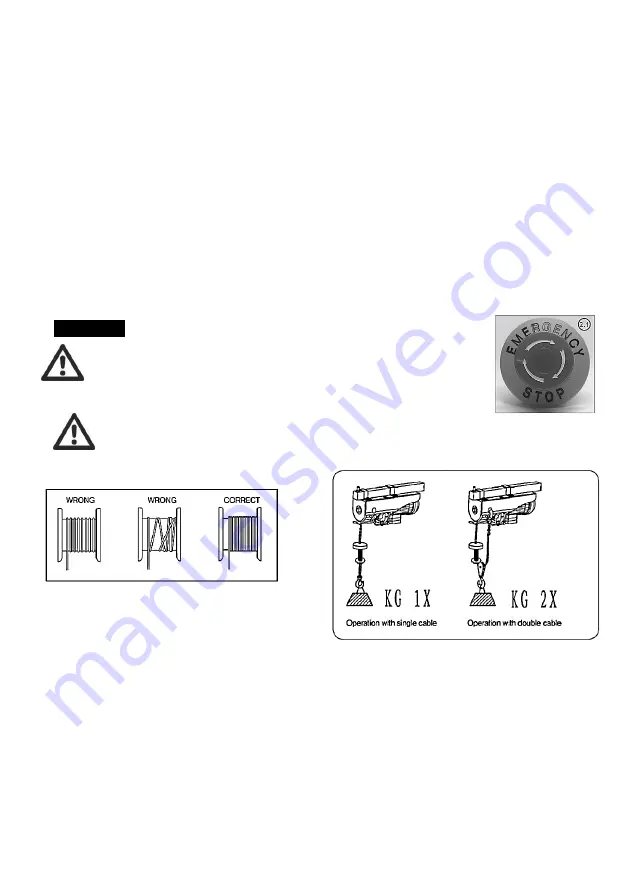

Check the cable of steel and if it shows areas damaged or reaches 20 hours of operation, replace

it immediately.

Be sure to pull cable into the

square

hole

of

rope drum, and then pull it out from the

round hole. With that

wind

the cable two circles and then pull it to the baffle which is side of cable

drum and fix it.

•

Check the brake disc and every 20 hours of operation, make a dynamic load test weighing

1.1 times rated load (lift a weight of 275 kg with simple cable) to verify the effectiveness of

the brake disc. If the brakes are not working properly, replace broken parts immediately.

•

Check the hook and replace it immediately if it is damaged or shows signs of wear sharp.

•

Make sure there is enough lubricant on parts. Every six months lubricating hook, drum and

bearings.Every time the cable is replace, lubricating the drum bearings.

Operation

WARNING! IN case of any abnormal noise, immediately turn off the

tool by pressing emmergency switch and contact an authorized

service facility for repairs

T

his

machine

is designed for

operating type S3 20

%

-

10 min

(periodic

intermittent

operation), which

means that the device

can

be

operated at

rated load for

2

minutes during

each operating cycle and

must then be

switched

off

for 8.

0

minutes to

cool off.

Operation with single cable

•

Prior to

starting work,

please be

sure

that the

steel cable

is

wound

up

exactly,

layer next to

layer

on

the cable drum. Never unwind the cable completely.

Unwind the

cable only

to the

point that

at

least

3

more layers

are

located

on

the drum. If the red indicator mark is

visible

,

please stop

the

cable winch

immediately

•

The

cable winch

is

operated

using the

operating

panel (10). When

operating

the upper

position

of

the switch, the load is hoisted up.

When operating

the lower position, the load is

lowered

.

Always

stop

the

cable winch prior

to

changing

.

•

Upon lowering a load,

please

remember that the

cable

hoist may

still

unwind

a

few more

centimetres

after

it

was stopped.

Therefore

,

please

stop

in

sufficient

time.

•

Operate the red Emergency Stop button (9) to immediately stop the winch in case of