BAROMETRIC BY-PASS SET-UP PROCEDURE

BAROMETRIC BY-PASS SET-UP PROCEDURE

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- info@ewccontrols.com

3

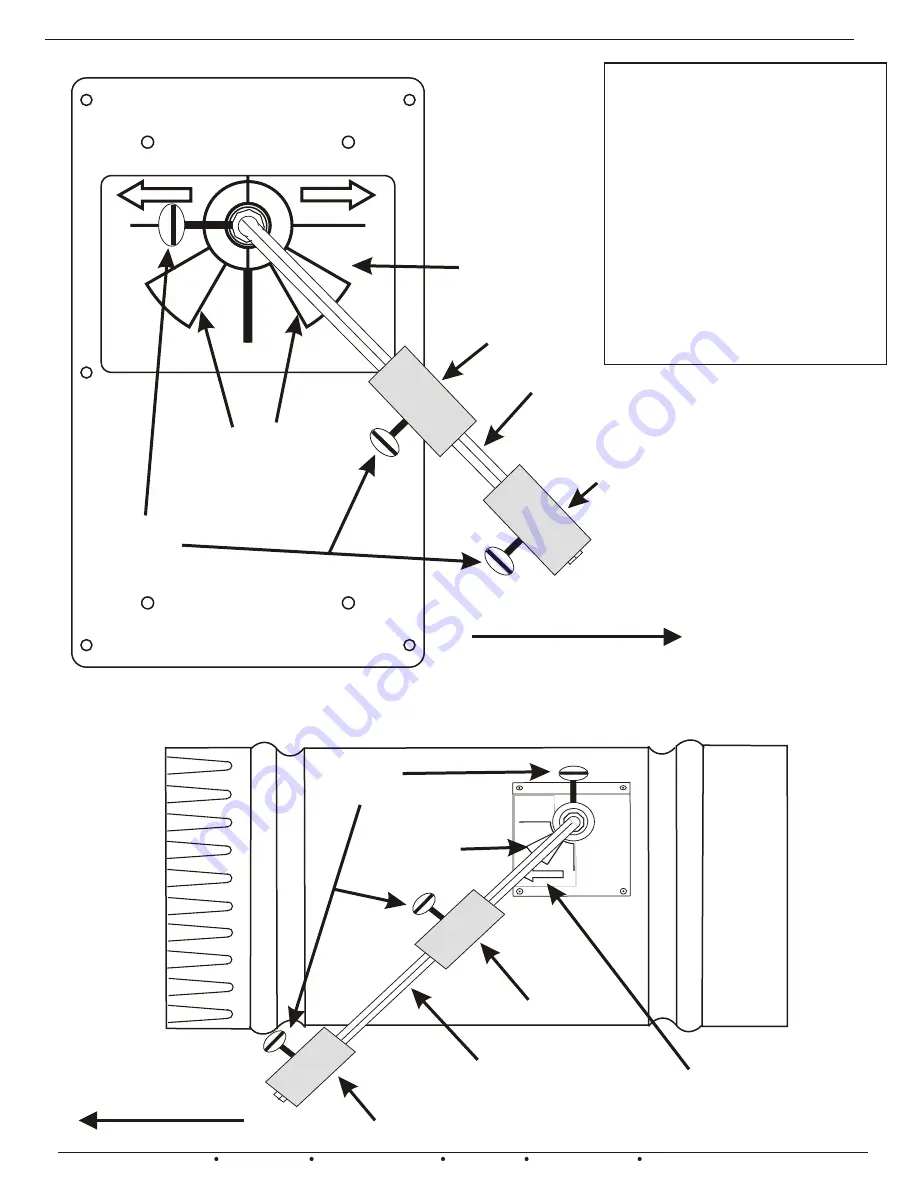

The direction of airflow can

be reversed on the PRD if

Contact EWC Controls Inc.,

Te c h n i c a l s u p p o r t i f

necessary for further details.

necessary, by pushing the

Door over the stop on the

bottom of the damper frame.

Then, adjust the arm to the

proper position based on the

n e w a i r f l o w d i r e c t i o n .

3

4

5

6

7

8

9

POSITION ARM IN IDEAL LOCATION IF

AIR FLOW IS IN DIRECTION INDICATED

BY THE ARROW ABOVE

ID

E

A

L

A

R

M

LO

C

AT

IO

N

ID

E

A

L A

R

M

LO

C

AT

IO

N

AIRFLOW

AIRFLOW

POSITION ARM IN IDEAL LOCATION IF

AIR FLOW IS IN DIRECTION INDICATED

BY THE ARROW ABOVE

ARM

GRADUATED

ADJUSTMENT

SCALE

THUMB

SCREWS

IDEAL

ARM

LOCATION

WEIGHT #1

EXTRA WEIGHT

ID

EA

L

AR

M

LO

C

AT

IO

N

AIRFLOW

POSITION ARM

IN IDEAL

LOCATION

0

1

Model PRD - RD Round Bypass Damper

IDEAL

ARM

LOCATION

WEIGHT #1

THUMB

SCREWS

ARM

GRADUATED

ADJUSTMENT

SCALE

EXTRA WEIGHT

Model PRD - Rectangular Bypass Damper

This arm position reflects

Air-flow from Left to Right!

This arm position

reflects Air-flow from

Right to Left!