16

LIF TKIT- 0 S

16

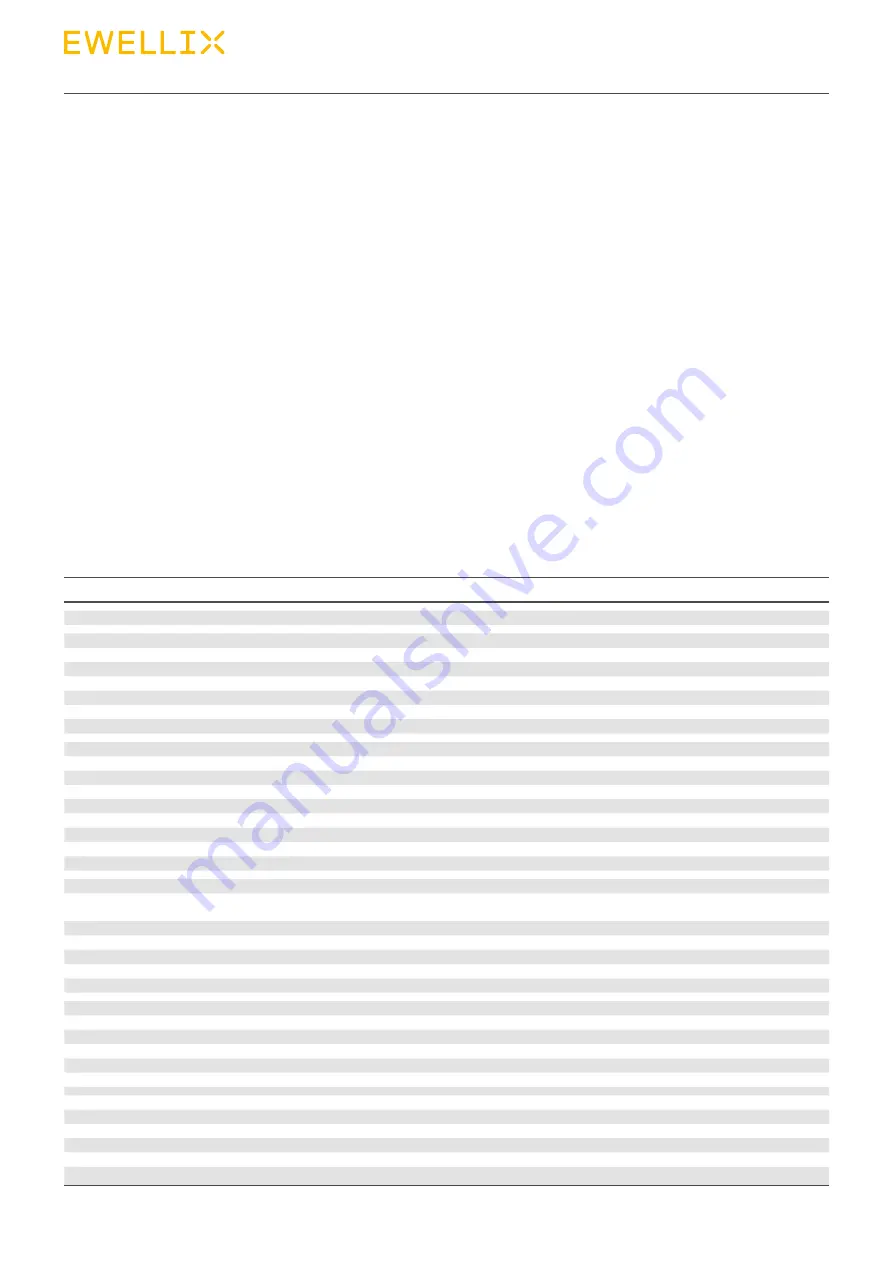

8.0 Specifications

44

Ver tic al axis fo r c o lla b orative ro b ots

Linear axis for collaborative

robots LIFTKIT-0S

Unit

LIFTKIT-0S-601

Pillar type

-

TLT

Performance Data

Max. Push load

N

1 500

Max. Pull load

N

0

Max. dynamic moment

Nm

210

Max. static moment

Nm

3 000

Max. linear speed

mm/s

80

Duty cycle

-

10% (20% at 500N)

Mechanical Data

Screw type

-

Acme screw

Stroke range

mm

500 - 900

Retracted length (software controlled)

mm

Stroke/2 + 275

Weight @ 0 mm stroke

kg

21

Δ weight per 500 mm stroke

kg

1,7

Robots compatibility

-

Any

Cable management

-

Threads on pillar and interface

-

plate to attach cable management

Electrical

Input Voltage/Current

-

120 VAC / 6,5 A

230 VAC / 3,3 A

Input frequency

Hz

50-60

Input Fuse

A

10

I/O voltage

-

24 VDC

I/O current

-

max. 10 A not protected

Emergency stop

-

STO up to PLe, Cat.4

Communication

Control interface

-

TCP/IP

Positioning, repeatability

mm

± 1

Accessible positions

-

any

Feedback

-

Position & Status

Soft start and stop

-

Implemented for smooth operation

Environment

Type of protection

-

IP40 in operational state

Ambient temperature

°C

+10 to +40

Max. humidity

%

85

Altitude

m

2 000

Vibration

-

Stationary industrial environment

Technical data

Operating range extension

• Vertical lifting of the cobot by up to

900 mm (1 400 mm on request) with

compact retracted height

• Robust pillar design for industrial use,

vibration free motion and virtually

maintenance free

Plug-and-play solution

• Hardware interface compatible with

any robots

• LIFTKIT control through TCP/IP

Cost savings and higher

productivity

Cobots combined with Ewellix LIFTKIT

provide a cost-effective solution to up-

grade an existing assembly shop, mov-

ing from a manual handled to a fully

automatized line.