Design and function

MIG/MAG welding

22

099-005592-EW501

16.07.2018

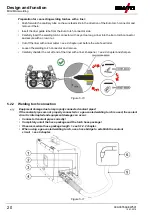

Figure 5-12

Item Symbol

Description

0

1

Carrier pin

For fixing the wire spool

2

Knurled nut

For fixing the wire spool

• Loosen knurled nut from spool holder.

• Fix welding wire reel onto the spool holder so that the carrier pin locks into the spool bore.

• Fasten wire spool using knurled nut.

5.2.3.3 Changing the wire feed rollers

Unsatisfactory welding results due to faulty wire feeding! Wire feed rollers must be suitable for

the diameter of the wire and the material.

• Check the roller label to verify that the rollers are suitable for the wire diameter.

Turn or change if necessary!

• use V-groove rollers with for steel wires and other hard wires,

• use U-groove rollers for aluminium wires and other soft, alloyed wires.

• Slide new drive rollers into place so that the diameter of the wire used is visible on the drive roller.

• Screw the drive rollers in place with knurled screws.

Figure 5-13

5.2.3.4 Inching the wire electrode

CAUTION

Risk of injury due to welding wire escaping from the welding torch!

The welding wire can escape from the welding torch at high speed and cause bodily

injury including injuries to the face and eyes!

• Never direct the welding torch towards your own body or towards other persons!