Rectifying faults

Checklist for rectifying faults

30

099-005592-EW501

16.07.2018

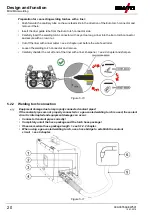

Categories legend (resetting the error)

a) The error message will disappear once the error has been rectified.

b) The error message can be reset by pressing a push-button:

Welding machine control

Push-button

RC1 / RC2

Expert

Expert 2.0 / Expert XQ 2.0

CarExpert / Progress (M3.11)

alpha Q / Concept / Basic / Basic S / Synergic /

Synergic S / Progress (M3.71) / Picomig 355

not possible

c) The error message can only be reset by switching the machine off and on again.

The shielding gas error (Err 6) can be reset by pressing the "Welding parameters" key button.

7.2

Checklist for rectifying faults

The correct machine equipment for the material and process gas in use is a fundamental

requirement for perfect operation!

Legend

Symbol

Description

Fault/Cause

Remedy

Coolant error/no coolant flowing

Insufficient coolant flow

Check coolant level and refill if necessary

Air in the coolant circuit

Vent coolant circuit

Wire feed problems

Contact tip blocked

Clean, spray with anti-spatter spray and replace if necessary

Setting the spool brake

> see 5.2.3.5 chapter

Check settings and correct if necessary

Setting pressure units

> see 5.2.3.4 chapter

Check settings and correct if necessary

Worn wire rolls

Check and replace if necessary

Wire feed motor without supply voltage (automatic cutout triggered by overloading)

Reset triggered fuse (rear of the power source) by pressing the key button

Kinked hose packages

Extend and lay out the torch hose package

Wire guide core or spiral is dirty or worn

Clean core or spiral; replace kinked or worn cores