Design and function

MMA welding or gouging

24

099-005592-EW501

16.07.2018

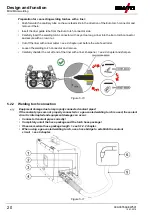

5.2.3.5 Spool brake setting

Figure 5-15

Item Symbol

Description

0

1

Allen screw

Securing the wire spool retainer and adjustment of the spool brake

• Tighten the Allen screw (8 mm) in the clockwise direction to increase the braking effect.

Tighten the spool brake until the wire spool no longer turns when the wire feed motor stops but

without it jamming during operation!

5.2.4

Standard MIG/MAG torch

The MIG welding torch trigger is essentially used to start and stop the welding process.

Operating elements

Functions

Torch trigger

• Start/stop welding

5.2.5

MIG/MAG special-torches

5.2.5.1 Switching between Push/Pull and intermediate drive

WARNING

Do not carry out any unauthorised repairs or modifications!

To avoid injury and equipment damage, the unit must only be repaired or modified by

specialist, skilled persons!

The warranty becomes null and void in the event of unauthorised interference.

• Appoint only skilled persons for repair work (trained service personnel)!

Dangers resulting from failure to perform test after conversion!

Before reconnection, “Inspection and Testing during Operation” according to

IEC/BS EN 60974-

4 “Arc welding systems – Inspection and Testing during Operation”

has to be performed!

• Perform test to IEC / DIN EN 60974-4!

The plugs are located directly on the M3.7X printed circuit board.

Plug

Function

on X24

Operation with Push/Pull welding torch (factory setting)

on X23

Operation with intermediate drive

5.2.6

Welding task selection

For selection of the welding task and for general operation see the relevant Control operating instructions.