Design and function

MIG/MAG welding

28

099-005593-EW501

10.01.2022

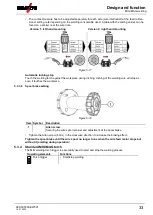

5.3.3 Wire feed

CAUTION

Risk of injury due to moving parts!

The wire feeders are equipped with moving parts, which can trap hands, hair, clothing

or tools and thus injure persons!

• Do not reach into rotating or moving parts or drive components!

• Keep casing covers or protective caps closed during operation!

Risk of injury due to welding wire escaping in an unpredictable manner!

Welding wire can be conveyed at very high speeds and, if conveyed incorrectly, may es-

cape in an uncontrolled manner and injure persons!

• Before mains connection, set up the complete wire guide system from the wire spool to the

welding torch!

• Check wire guide at regular intervals!

• Keep all casing covers or protective caps closed during operation!

5.3.3.1 Inserting the wire spool

CAUTION

Risk of injury due to incorrectly secured wire spool.

If the wire spool is not secured properly, it may come loose from the wire spool support

and fall to the ground, causing damage to the machine and injuries.

• Make sure to correctly fasten the wire spool to the wire spool support.

• Before you start working, always check the wire spool is securely fastened.

Standard D300 wire spool holder can be used. Adapters are required when using standardised

basket coils (DIN 8559)

> see 9 chapter

.

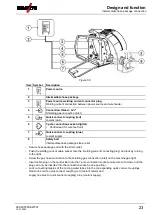

Figure 5-13

Item Symbol Description

0

1

Carrier pin

For fixing the wire spool

2

Knurled nut

For fixing the wire spool

• Unlock and open protective flap.

• Loosen knurled nut from spool holder.

• Fix welding wire reel onto the spool holder so that the carrier pin locks into the spool bore.

• Fasten wire spool using knurled nut.