Functional characteristics

TIG welding

44

099-00L200-EW501

13.05.2022

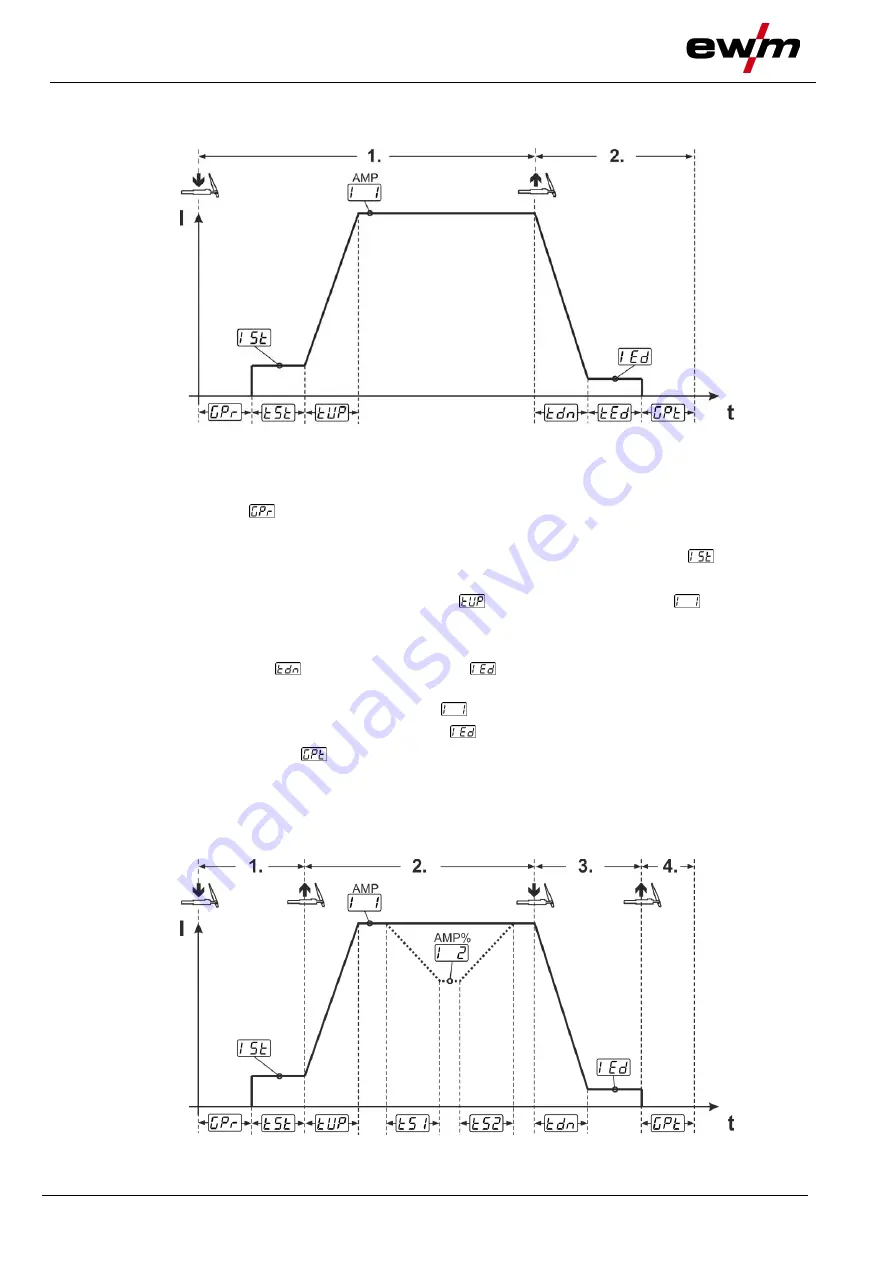

5.1.7.2 Non-latched mode

Sequence

Figure 5-17

1

st

cycle:

• Press and hold torch trigger 1.

• Gas pre-flow time

elapses.

• HF start pulses jump from the electrode to the workpiece. The arc ignites.

• The welding current flows and immediately assumes the value of the ignition current

.

• HF switches off.

• The welding current ramps up to the main current

within the set up-slope time

(AMP).

2

nd

cycle:

• Release torch trigger 1.

• The main current falls

to the end-crater current

(minimum current) in the set down-slope time.

When the 1

st

torch trigger is pressed during the down-slope time,

the welding current returns to the set main current

.

• The main current reaches the end-crater current

; the arc is extinguished.

• the set gas post-flow time

elapses.

When the foot-operated remote control is connected, the machine switches automatically to non-latched

operation. The up- and down-slopes are switched off.

5.1.7.3 Latched mode

Sequence

Figure 5-18