Functional characteristics

TIG welding

52

099-00L200-EW501

13.05.2022

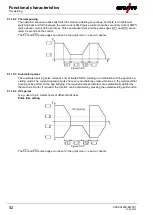

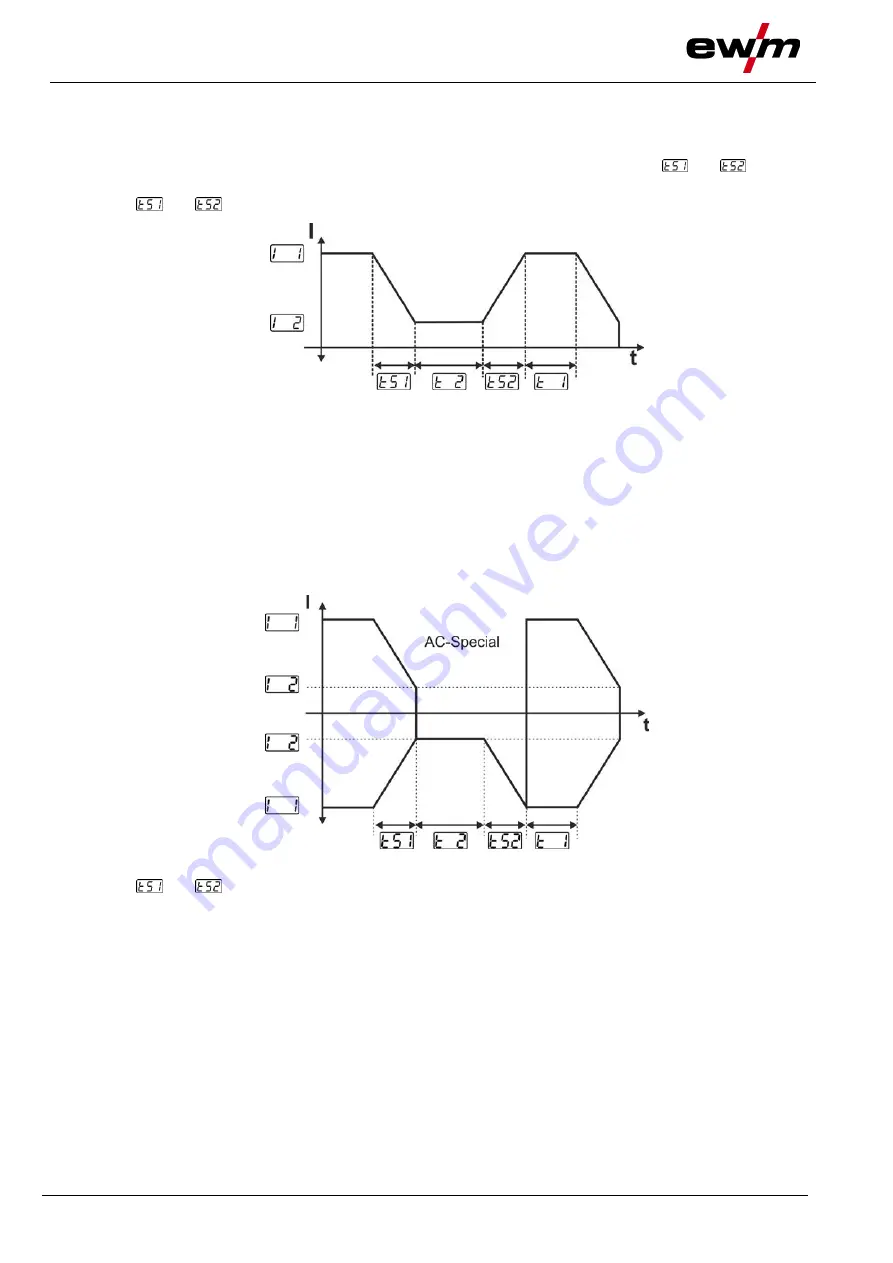

5.1.10.2 Thermal pulsing

The operation sequences basically match the standard welding sequences, but there is an additional

switching back and forth between the main current AMP (pulse current) and the secondary current AMP%

(pulse pause current) at the set times. Pulse and pause times and the pulse edges (

and

) are en-

tered in seconds on the control.

The

and

pulse edges can be set in the quick menu

> see 4.4 chapter

.

Figure 5-26

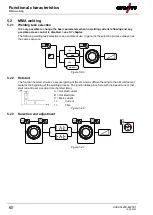

5.1.10.3 Automated pulses

The automated pulsing pulse variant is only activated for DC welding in combination with the spotArc op-

erating mode. The current-dependent pulse frequency and balance create vibrations in the weld pool that

have a positive effect on the gap bridging. The required pulse parameters are automatically defined by

the machine control. If required, the function can be disabled by pressing the pulsed welding push-button.

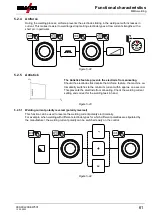

5.1.10.4 AC special

Is e.g. used to join metal sheets of different thickness.

Pulse time setting

Figure 5-27

The

and

pulse edges can be set in the quick menu

> see 4.4 chapter

.