Functional characteristics

TIG welding

099-00L200-EW501

13.05.2022

41

5.1.5 Synchronous welding (AC)

This function is important when welding with two power sources on both sides, simultaneously with alter-

nating current, as is the case, for example, with thick aluminium materials in position PF. This ensures

that with alternating current, the positive and negative pole phases occur simultaneously on both power

sources (are synchronised) and the arcs, therefore, do not affect one another.

Figure 5-14

The phase sequences and rotating fields of the supply voltages (50Hz / 60Hz) must be identical to ensure

that the energy is introduced into the weld pool without problems during synchronous welding. The re-

quired parameters can be set directly on the machine control (no turning or reconnecting of the mains

connection plug is required).

Wiring differences in the supply network are also compensated. Optimum phase compensation immedi-

ately shows better welding results. Two EWM power sources can be synchronised using the phase

shift

parameter in steps of 60° (0°, 60°, 120°, 180°, 240° and 300°).

When synchronising with a third-party product (power source), the parameter Phase fine-tuning

can

be adjusted in steps of 1° (-30° to 0° to +30°) in addition to the phase position.

5.1.6 Arc ignition

The type of ignition is set in the System menu (push-button ). Additional ignition options can be ad-

justed, if needed.

Selection

System settings

Power source

Ignition

HF start

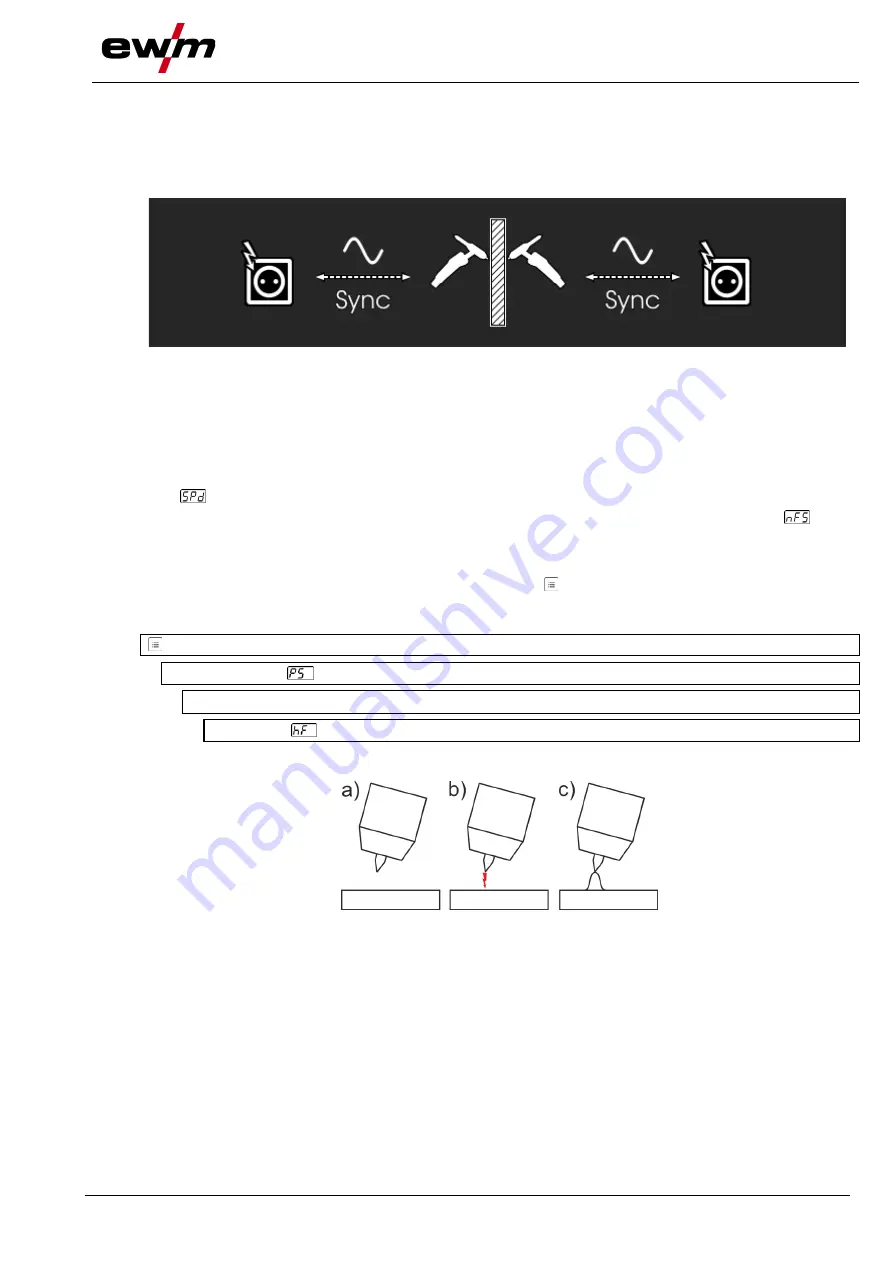

5.1.6.1 HF ignition

Figure 5-15

The arc is started without contact using high-voltage ignition pulses:

a) Position the welding torch in the welding position above the workpiece (distance between the elec-

trode tip and the workpiece approx. 2-3 mm).

b) Press the torch trigger (high-voltage ignition pulses start the arc).

c) Depending on the selected operating mode, the welding current flows with the set start or main cur-

rent.

Ending the welding process: Release the torch trigger or press and release depending on the selected

operating mode.