Design and function

Shielding gas supply (shielding gas cylinder for welding machine)

099-000159-EW501

16.08.2016

31

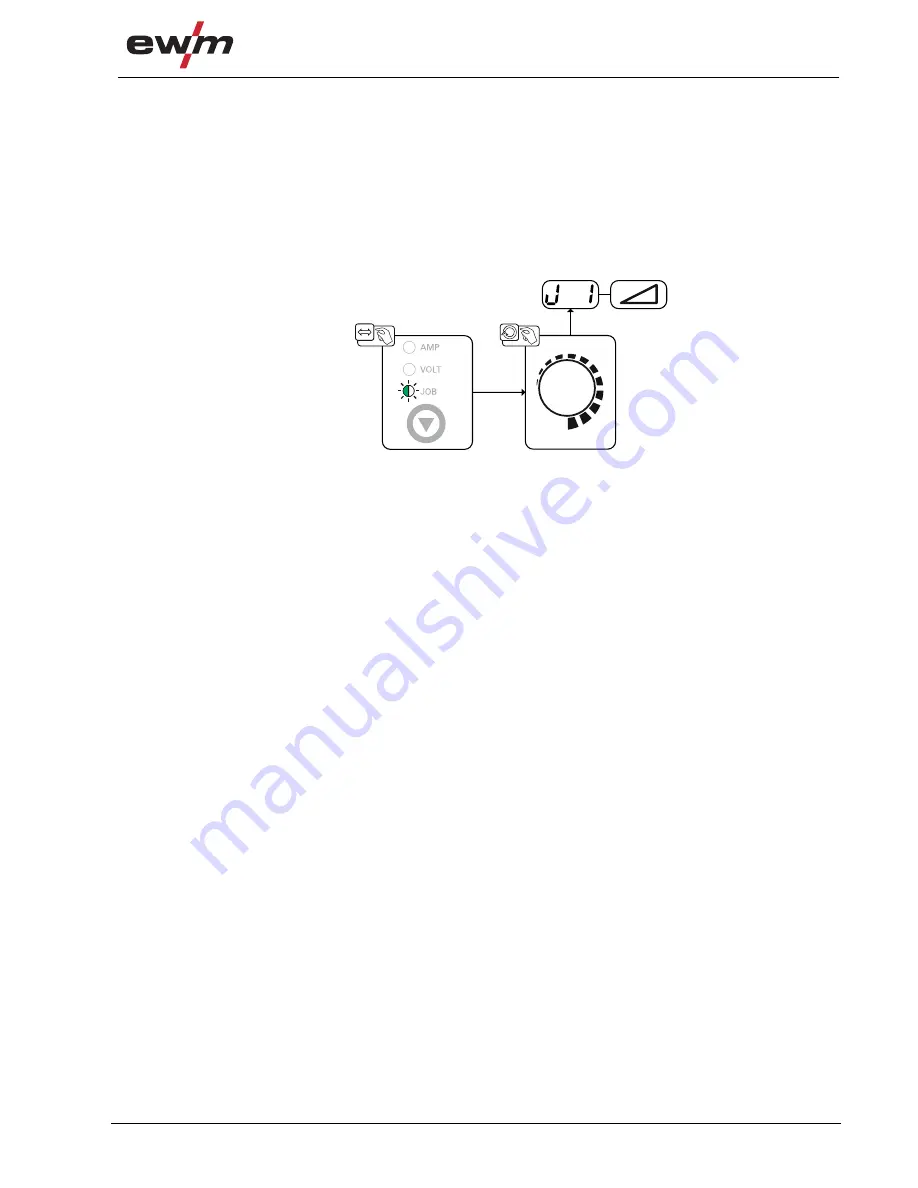

5.10.3.1 Recurring welding tasks (JOB 1–7)

The user has 7 more memory locations at their disposal to save recurring or different welding tasks on a

permanent basis. To do so, simply select the required memory location (JOB 1–7) and the welding task is

set as described previously.

The three rotary knobs for AC frequency, AC balance and the tungsten electrode diameter are

exceptions. These settings are made in the operation sequence (signal lights with same name).

Switching a JOB is only possible if no welding current flows. Up-slope and down-slope times can be set

individually for latched and non-latched operation.

Selection

Figure 5-13

When one or more of the recurring welding tasks (JOB 1–7) has been selected the JOB signal light

comes on.

5.10.3.2 Welding parameter setting

The parameters that can be set in the function sequence of the machine control depend on the selected

welding task. This means that if for example you have not selected a pulse variant, then you cannot set

any pulse times in the function sequence.