EX-TECH-SIG-SAS-12-SD125-150-TM-EN-REV04

the area over which both the sounder and beacon

requirement.

warning signal

must be audible and visible. The unit

Remove End Cover

should only be fixed to servies that can carry the weight

of the unit.

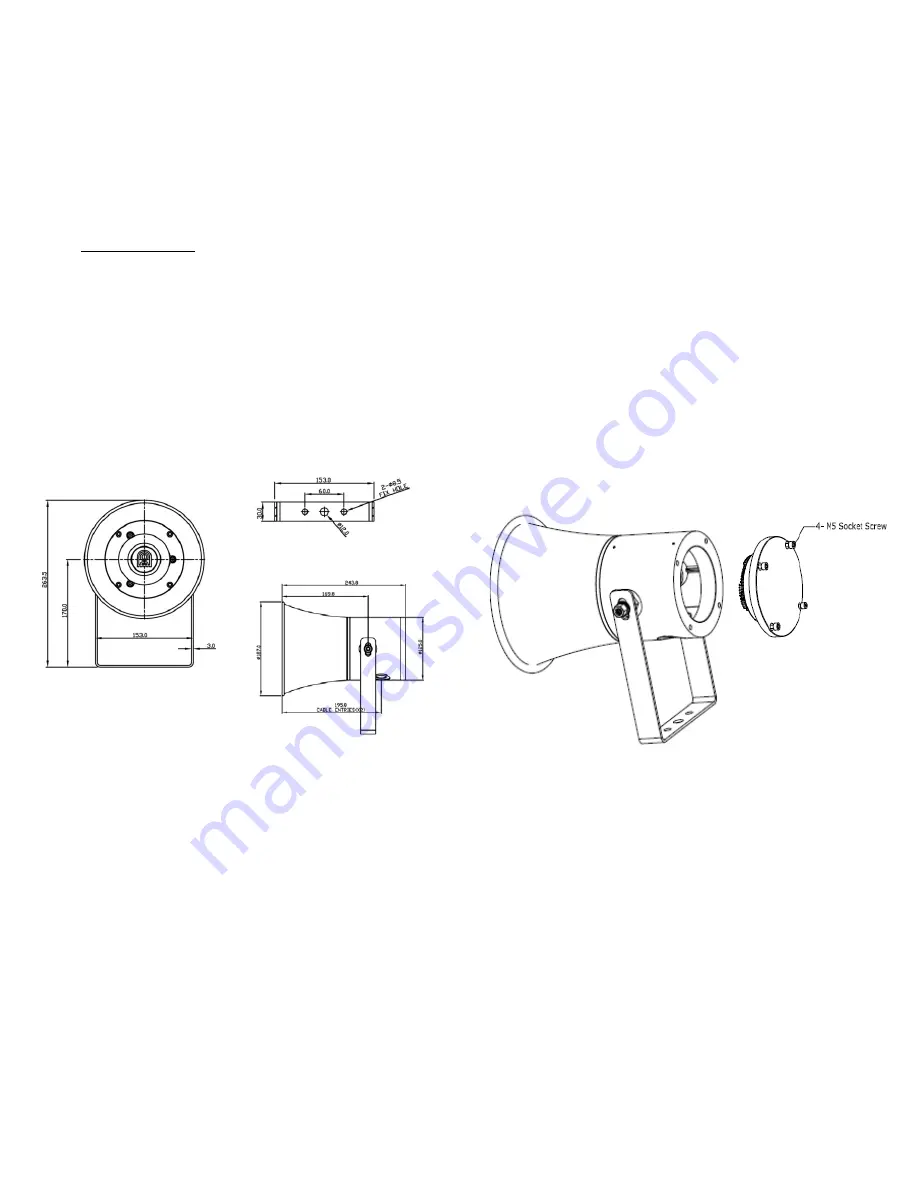

Mounting

Bracket Mounting

Unscrew the six (6 for BC 150 and 4 for BC 125) M5

retained hex socket head screws of the end cover. This

will release the cover from the base. Before replacing the

cover, check that the flameproof joints are clean and not

damaged, the gasket is still retained in

The SD150/ 125 mounts ‘U’ shaped stainless steel

its groove

via a bracket by using one 12mm diameter and two

8.5mm diameter bolt holes in the center of the bracket.

The alignment and positions can be adjusted by

loosening the two M8 screws, which fastened the stainless

CAUTION

: Before removing the cover, ensure the power

to the product is isolated. Remove the six pieces of M5

socket screws to open the cover. Twist the cover gently

clockwise and anti-clockwise, whilst pulling away from the

steel bracket to the sounder. The sounder should be

base, until it comes off. Replace the cover in similar way,

positioned such that dust, debris or water cannot enter into

the horn opening.

but operate in reverse manner as above.

6.0 WIRING

General Requirement

EX-TECH SIGNALLING SAS recommends that all cables and

cores should be fully identified (suggest using cable from 2.0 to 2.5

mm²).

Ensure that all nuts, bolts and screws are secured. Ensure that only

the right and certified cable glands are used and earthed correctly.

Ensure that only the rig t and certified stopping plugs are used

to blank off unused gland entry points. In order to maintain the IP

rating of the product, we recommend SS316L for this application.

Cable Connection

The cable connection is connected with the terminal

blocks on the electronic

PCB

assembly located in the

flameproof enclosure of sounder. Cable connection should

be suitably approved for the installation requirements

Power Supply

up to 48V DC or 100-254V AC

PCB WIRING TERMINALS

Apply power supply to up to 48V DC o r 100-250V AC to ‘L’ &

‘N’ (See Fig 1)

Four Alarm Stages

No sound for Stage 1. There will be sounds for the subsequence

Stages:

Stage 1: apply power supply to ‘L’ & ‘N’

Stage 2; connect S1 to 0/ com

Stage 3: apply power supply to ‘L’ & ‘N’ and connect

S2 to 0/COM

Stage 4: apply power supply to ‘L’ & ‘N’ and connect S1, S2 to

0/COM. Stage DIY (Recording Sound) : supply to to ‘L’ apply

power& ‘N’ and connect DIY to 0/COM

Fig 1

Fig 2

3