1/13/2005

6

EXAKTOR

®

EXOA-2 BLADE COVER

DUST COLLECTOR

Installation

The

EXAKTOR

®

BladeCover/Dust Collector has been designed to fit most table saws with its vertical Mast installed at

either the right or left hand side of the machine. In most cases the vertical mast will be installed at the right hand end of the

saw’s table or table extension, close to the rear edge of the table.

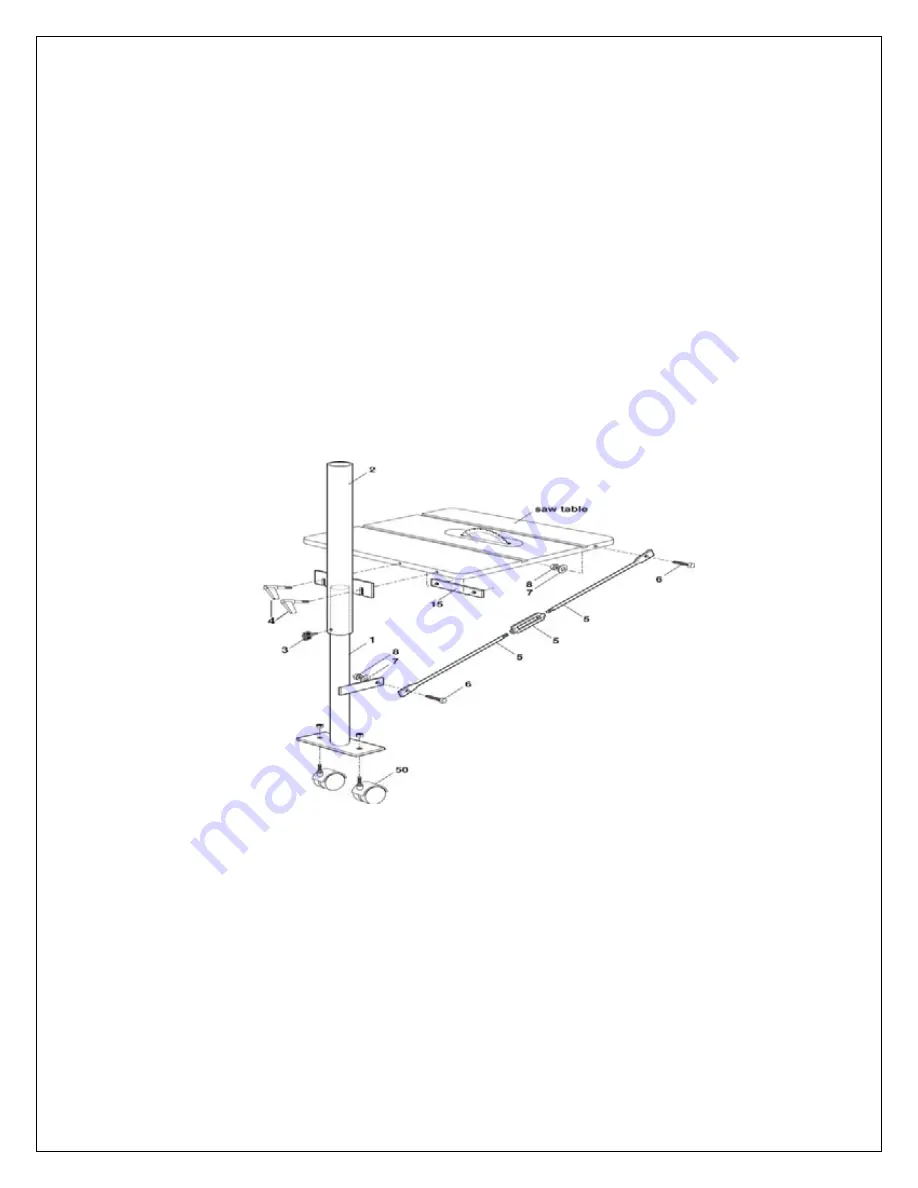

Mast Assembly

1.

With the Lower Mast (#1) resting on the floor, insert it into the bottom end of the Upper Mast (#2).

Adjust the overall length of the Lower and Upper Masts to where the top edge of the slotted Mounting Bracket,

that is welded on the side of the Upper Mast, will be just below the top surface of the saw’s table or table

extension. Lock the two Masts together with a Locking Knob (#3).

2.

Carefully place the slotted mounting bracket against the edge of the saw table, or table’s extension, close to

the rear

edge of the table. Make sure there is clearance behind the edge of the table to accommodate the Backing Plate

(#15). Its two threaded holes must line-up with the slot in the mounting bracket

.

3.

Using the slots in the Mounting Bracket as a

template, drill a 1/4” hole at the top of each slot,

through the edge of the table. Using two Locking

Levers (#4) and the Backing Plate (#15), fasten

the Mounting Bracket to the edge of the table.

4.

The diagonal brace is used to hold the

vertical mast in position. Use a ¼-20 x 1¼” Hex

Head Bolt (#6), Washer (#7) and ¼-20 Nut (#8)

to attach one end of the Mast Brace (#5) to the

bracket at the bottom end of the Lower Mast

(#1).

5.

Position the assembled Lower and Upper

Mast so

that it is vertical to the floor and square to the

surface of the saw table. Determine where to

place the

unfastened end of the Mast Brace up under the

rear edge of the saw’s table, or table extension so

that when the brace is fixed in place, and the

turnbuckle is tightened, the assembled Mast will

be held vertical and square to the table surface

and will not shift from that position. Drill an

appropriate hole in the rear edge of the saw table

or table extension and attach the

upper end of the

Mast Brace to the edge of the underside of the table.

Use Hex Head Bolt (#6), Washer (#7) and Nut (#8).