3. Determine the place where the wiper is to be installed. The dimensions are shown

below. The wiper can be installed in any position above or below the window.

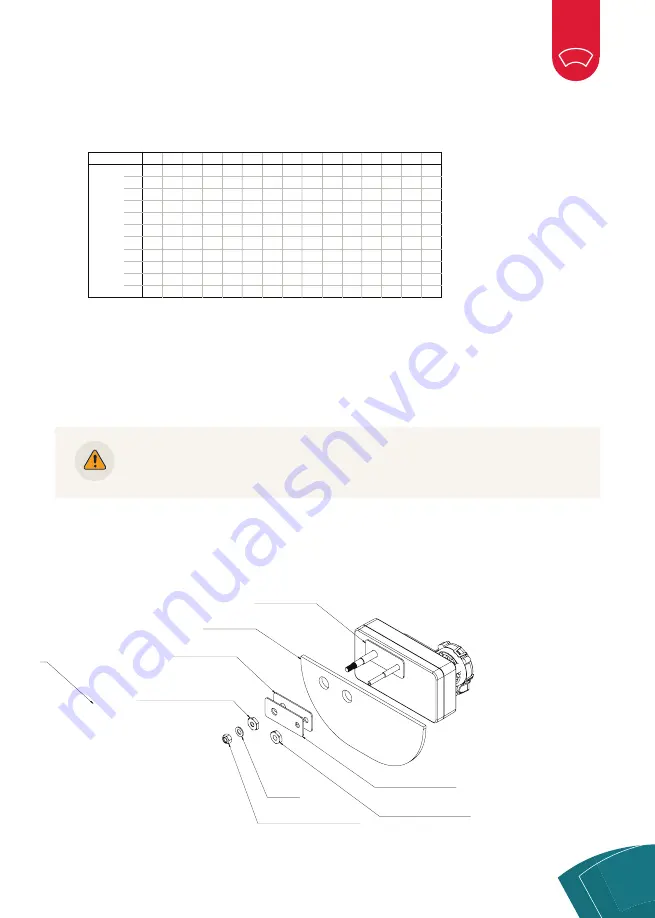

4. Place the windscreen wiper in the pre-drilled holes of the bulkhead (see fi gure). A rubber sealing

gasket must be placed at both sides of the bulkhead. Hole sizes are 1x clearance on M20,

1 clearance on M8 at 50 mm centers.

• The wipe arc-line closest to the intersection, shows the wipe arc;

• Find in the table below the vertical displacement of the blade (H);

Now the wiper blade length can be calculated:

Length of wiper blade = 0.9 * 2 * (E-H).

90° 86 103 117 132 146 161 176 190 205 220 234 249 264 278 293

263

250

105

85°

92

79

119 132 145 158

197

184

171

210 223 236

94

80°

82

70

105 117 129 140

175

164

152

187 199 211 222 234

83

75°

73

62

93 104 114 124

155

145

135

165 176 186 196 207

73

70°

63

55

81 90 100 109

136

127

118

145 154 163 172 181

63

65°

55

47

71 79 86 94

117

110

102

125 133 141 149 157

54

60°

47

40

60 67 74 80

100

94

87

107 114 121 127 134

45

55°

40

34

51 57 62 66

85

79

74

90 96 102 107 113

36

50°

33

26

43 47 52 56

70

66

61

75 80 84 89 94

30

45°

27

23

35 38 42 46

57

53

50

61 65 68 72 76

25

40°

21

19

26 30 34 37

45

43

40

48 51 54 57 60

400

Armlength (L)

350

300

450 500 550 600

750

700

650

800 850 900 950 1000

Determining the vertical displacement of the wiper blade

W

ipe ar

c

Vertical displacement of the blade (H)

Units in mm

Att ention!

When installing the wiper, reserve space for a housing or cover.

Bearing

Dogbone

Nut M10

Tightening 33Nm/24ft. lbs

Nut M8

Tightening 17Nm/12ft. lbs

Nut M11 Special

tightening torque 26Nm/19ft. lbs

Glass or Bulkhead

Rubber sealing plate

Pin

Hexagon locking nut

tightening torque 16.3Nm/12ft. lbs

Stainless steel sealing plate

Bearing

Rubber sealing plate

Glass or Bulkhead

Glass or Bulkhead

Rubber weathercap

Nut M8 Special

tightening torque 16.3/12ft. lbs

M8 washer

Tightening 16.3Nm/12ft. lbs

9

Exalto type 223KGC

MANUAL WIPER SYSTEMS