10

4.5. Final Inspection Checklist before

Operation

After installing the machine, a final inspection

should be performed by considering the following

checklist;

Any missing components, guards or panels

Removal of the shipping brace

Lost fasteners and fittings, hoses and

conduit

Missing or damaged items

Coolant, oil, or hydraulic leads

Tools and others materials left on saw

Safety measures, general condition and

readiness for use

5

OPERATION

In this section, the functions of the machine will

described to guide the operator to become familiar

with the machine and its components.

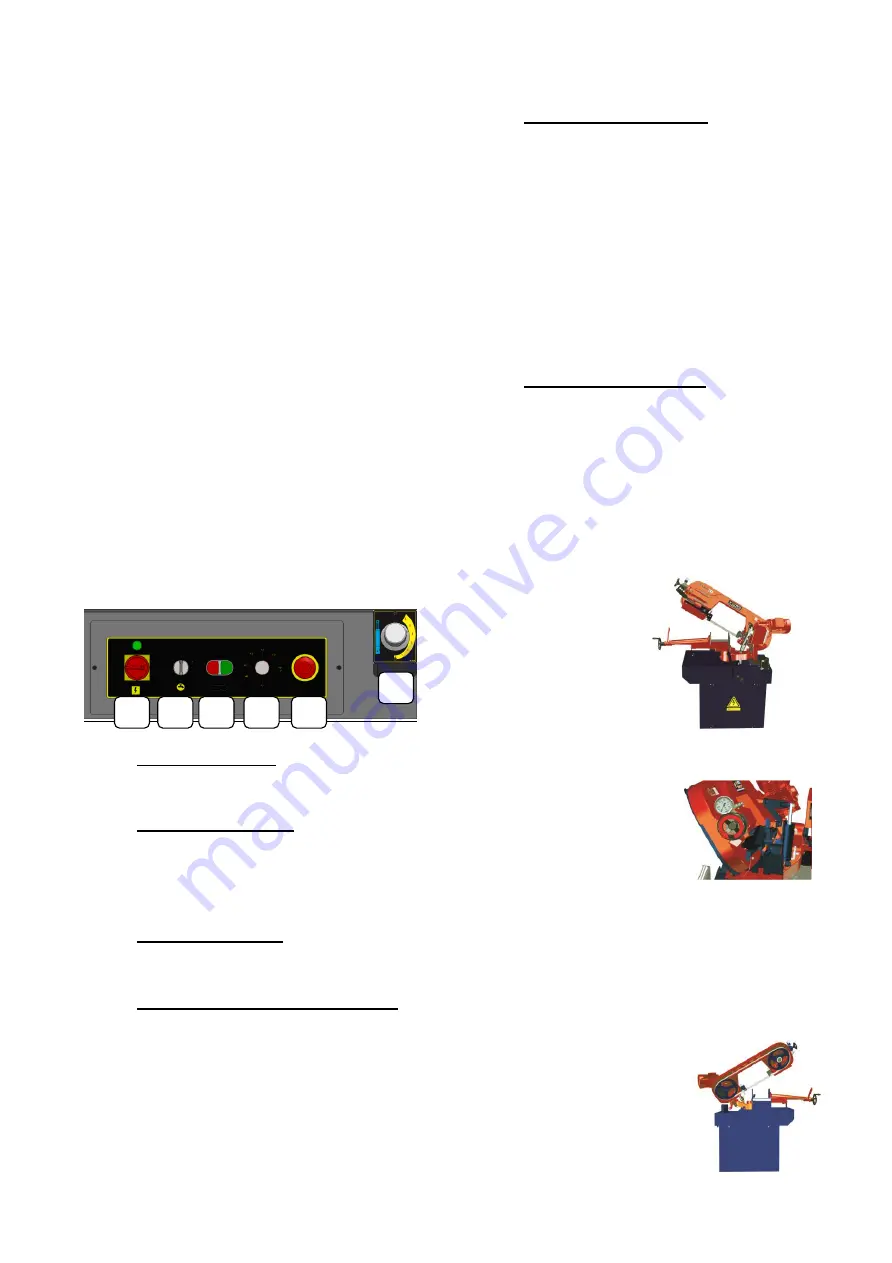

5.1 Control Panel

A) Main Power Switch

The machine is ready when the main power

switch is turned on.

B) Coolant Pump On/Off

Coolant pump switch on/off via this button.

Caution:

Do not operate the coolant motor while

coolant tank empty. Otherwise, the coolant motor

will be damaged.

C) Open/Close Switch

Cutting process can be started and stopped with

these buttons.

D) Blade Speed Arrangement Button

Blade speed can be adjusted 25-90 m/min by this

button.

E) Emergency Stop Button

The "Emergency stop" push button stops

all

functions

of the machine. The machine will not

function until "Emergency stop button’ is

released. To release the emergency button, turn it

in the direction indicated on its hub.

Caution:

The "Emergency stop" push button does

not disconnect the machine from the main power

supply. To avoid from serious injury or death due

to electricity shock, turn the main power switch off

or disconnect the machine from the main supply

before servicing it.

F) Bow Down Speed Valve

Bow down speed can be adjusted by this button.

5.2. Blade Changing Procedure

In order to achieve accurate and efficient cuts, it

is important to use a sharp and correct blade for

the material being cut.

1- Raise the saw frame to its highest

position.

2- Turn the hand-wheel to left to loosen the

blade.

3- Switch off the main power switch of the

machine.

Caution:

Avoid serious injury by turning the

machine's power off at the main switch before

adjusting, servicing, or cleaning the saw.

4-

Open all the wheel covers on the saw

frame.

A

B

C

D

E

F

Summary of Contents for PGM 280

Page 1: ...PGM 280 OPERATION MANUAL ...

Page 27: ...28 10 CONTROL CIRCUIT DIAGRAM ...

Page 28: ...29 11 POWER CIRCUIT DIAGRAM ...