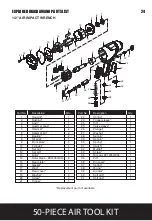

50-PIECE AIR TOOL KIT

D1

B1

C1

D1

B1

C1

D1

OPERATION

25

26

27

1/2" AIR IMPACT WRENCH

Torque in Forward

170 ft-lbs (+/- 10%)

280 ft-lbs (+/- 10%)

350 ft-lbs (+/- 10%)

Torque in Reverse

370 ft-lb (+/- 10%)

Setting

1

2

3

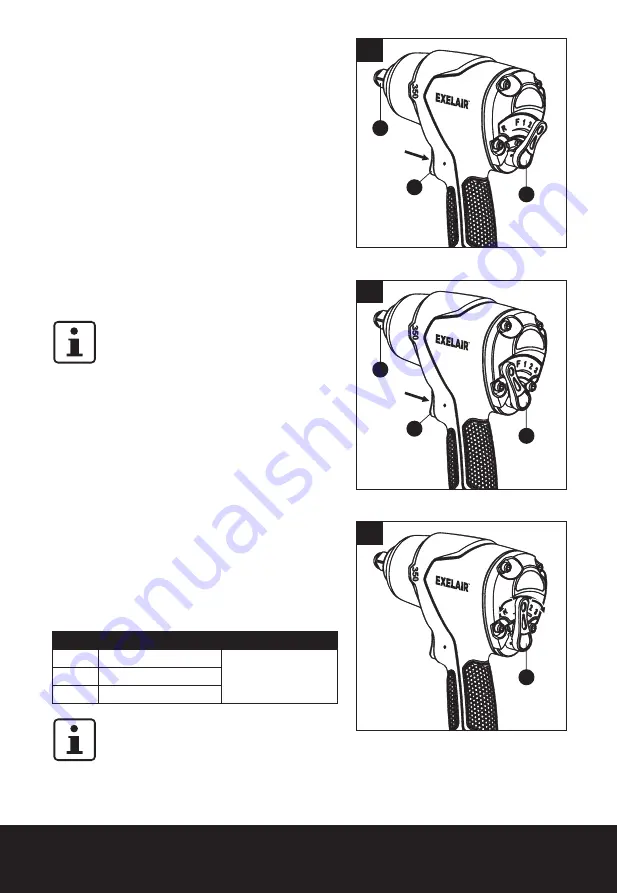

1. How to install/tighten threaded fasteners.

Push the switch (D1) forward and have the

arrow on the switch (D1) pointing at either of

the settings 1, 2, 3 as shown. Press the trigger

(C1). The tool anvil (B1) runs clockwise.

(See Figure 25)

2. How to remove/loosen threaded fasteners.

Push the switch (D1) backward and have the

arrow on the switch (D1) pointing at “R”

position as shown. Press the trigger (C1).

The tool anvil (B1) runs counterclockwise.

(See Figure 26)

NOTE:

This tool features a power

regulator valve. 3 Turn the switch (D1)

slowly forward until desired output is

achieved. The Settings 1, 2, 3 do not

denote a specific power output but are

only for reference. "Setting 1" is the

least amount of power, which is suitable

for just mounting threaded fasteners on

workpiece while "Setting 3" is the

greatest amount of power, which is for

tightening threaded fasteners on

workpiece. This tool operates in

maximum power in reverse, which

releases threaded fasteners from

workpiece with ease. Choose the

correct torque needed on workpiece

when mounting or releasing threaded

fasteners by understanding the

reference torque listed below.

(See Figure 27)

NOTE:

Make sure that this tool has the

co rrect torque to tighten/release

threaded fasteners. The torque applied

to threaded fasteners can be found in

theirinstructions or manuals.

19