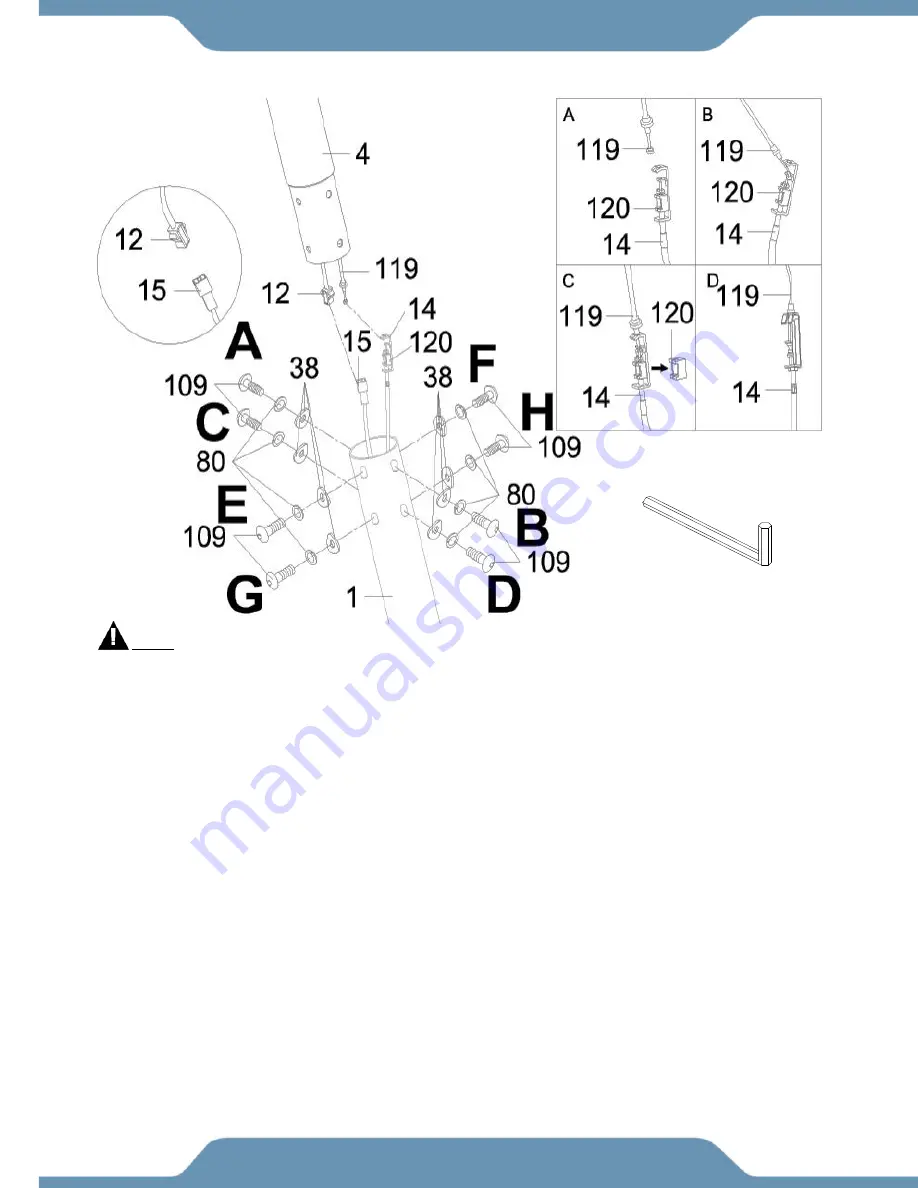

14

ASSEMBLY

MUST

TIGHTEN

IN

SEQUENCE:

A,B,C,D,E,F,G,H.

Step 4

Assembly of Front Post.

Use the

5mm Allen Wrench

to remove eight

Hexagon Socket Head Bolts (109)

, eight

Spring

Washers (80)

, and eight

Curve Washers (38)

from the

Front Post (4)

. Put these hardware aside.

Thread the

Tension Control Knob Cable (116)

cable coming out from under

Main Post (4)

into

the cable lock end of the

Tension Cable (14)

. See

Figure A

. Once the

Tension Control Knob

Cable (116)

is in place, give it a good tug upwards into the slot of the metal bracket of the

Tension

Cable (14)

. See

Figure B

. Remove the

Clip (120)

from the cable lock end of the

Tension Cable

(14)

.

Figure

C

. If threaded correctly, the connection should look like

Figure D

.

Connect the

Console Extension Wire (12)

from the

Front Post (4)

with the

Extension Sensor

Wire (15)

from the

Main Frame (1)

.

Insert the

Front Post (4)

into the

Main Frame (1)

. Reinstall the previously removed hardware: eight

Hexagon Socket Head Bolts (109)

, eight

Spring Washers (80)

, and eight

Curve Washers (38)

and securely tighten the bolts using the

5mm Allen Wrench

provided.

5mm Allen Wrench

1PC

Tool:

Summary of Contents for 1317.5-101016

Page 2: ......

Page 5: ...3...

Page 6: ...4 LABEL PLACEMENTS...

Page 8: ...6 OVERVIEW DRAWING 1 1 6 1 1 6 1 3...

Page 12: ...10 HARDWARE TOOLS PACK...