3005831-2019-04-01.fm

Technical electrical connections (EXcon control

35/64

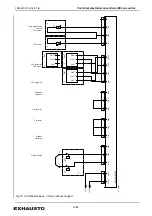

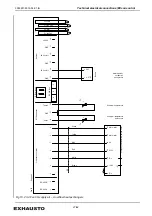

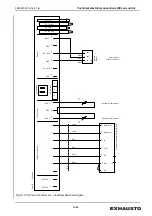

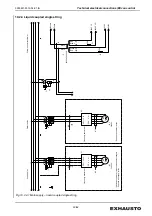

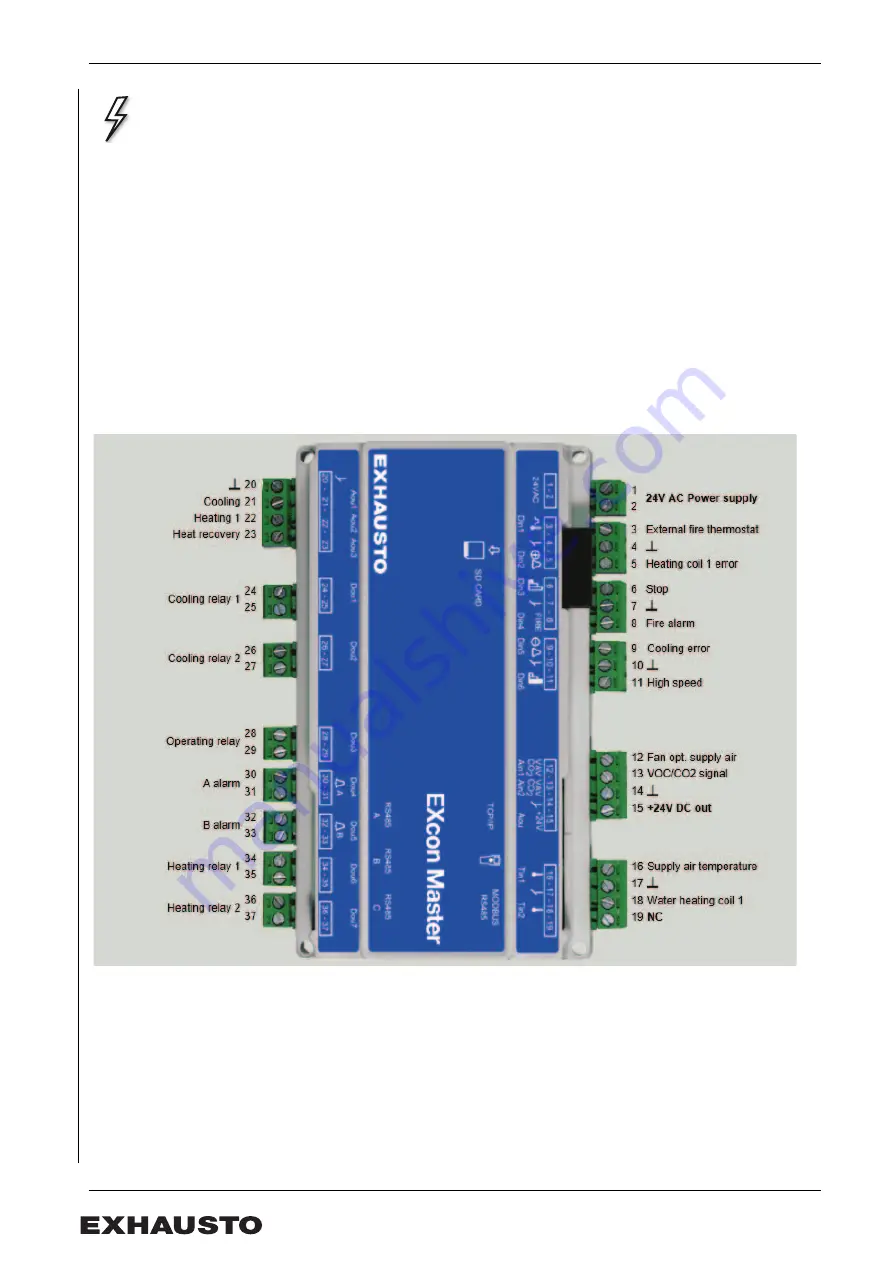

10.Technical electrical connections (EXcon control system)

10.1Control system component names

The figures below are found in the web user interface under

Service > Master

>

Connection EXconMaster.

NB

The subsequent installation of components requires a reconfiguration of the

control system and requires another pin allocation than that shown.

Contact EXHAUSTO for more information.

EXcon Master

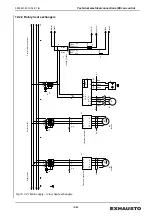

The figure shown below is found in the web user interface under

Service > Master

>

Connection EXconMaster.

Summary of Contents for VEX5000 Series

Page 63: ...3005831 2019 04 01 fm Spare parts 63 64...

Page 64: ......