Maintenance

Periodic Maintenance

Check Blower

Housing/Impeller

Service Interval: Before each use or daily

1.

Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2.

Inspect for wear or damage daily. Replace or

repair worn parts as needed.

Note:

When mowing in areas with sandy soil,

use low lift blades on the cutting deck and higher

cutting heights to minimize wear on the blower

components.

Check Bags

Service Interval: Before each use or daily

1.

Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2.

Inspect the bags for wear, tears, or damage.

WARNING

Under normal use the bag will deteriorate and

wear. Objects could exit through worn bag

at high speeds. Thrown objects can cause

serious injury or kill you or bystanders.

Check bags frequently for tears and holes.

Replace worn bags only with Exmark

replacement bags.

Check Condition of Belt

Service Interval: Every 50 hours

All Units

1.

Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2.

Inspect the belt for damage or wear. Replace belt

with one of the following:

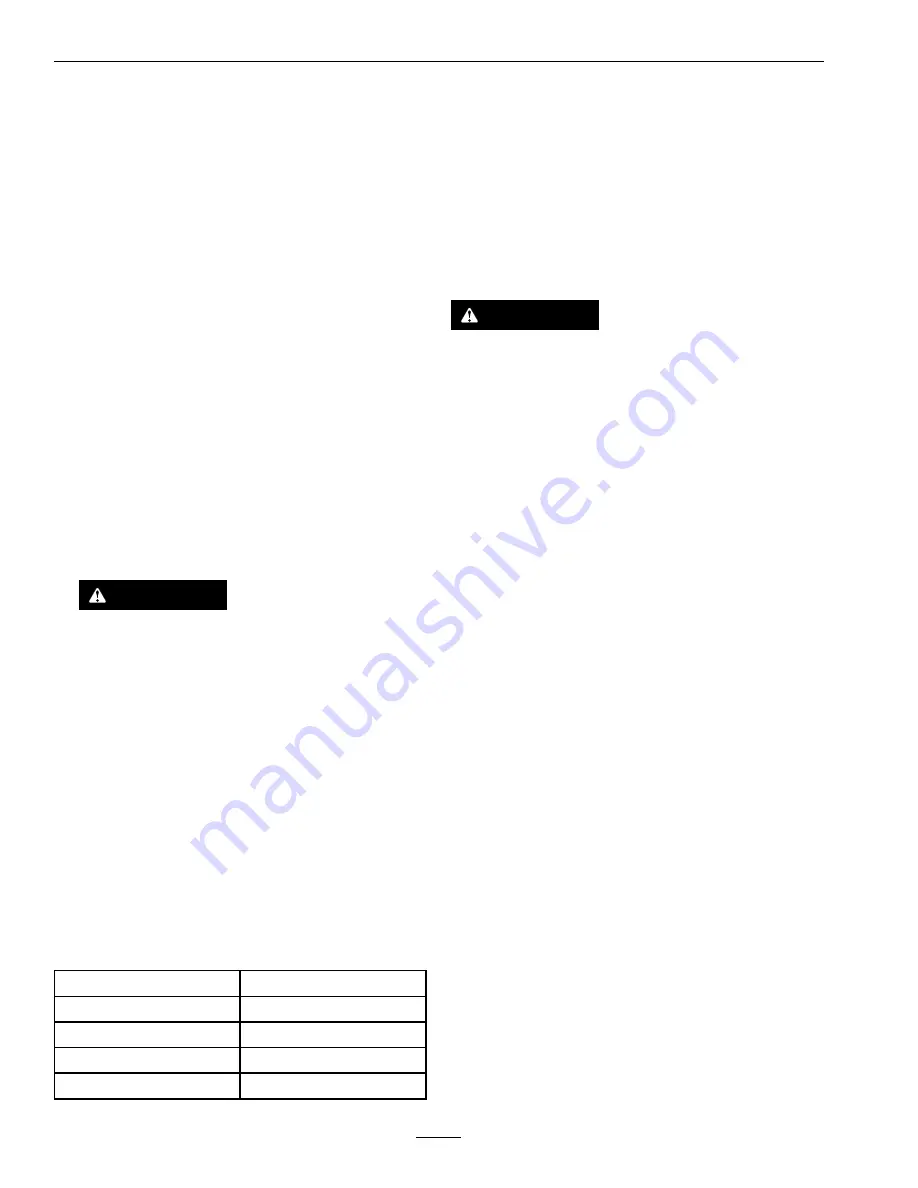

Deck

Part No.

44 inch

119-1566

48 inch

116-4844

52 inch

1-653333

60 inch

703636

Cleaning

Clean Muffler and Rear

Frame Area

Service Interval: Before each use or daily

Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

WARNING

Operating engine parts, especially the muffler,

become extremely hot. Severe burns can occur

on contact and debris, such as leaves, grass,

brush, etc. can catch fire.

•

Allow engine parts, especially the muffler, to

cool before touching.

•

Remove accumulated debris from muffler and

engine area.

Clean Rear Screen In Hopper

Service Interval: Before each use or daily

1.

Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2.

Open hopper and remove clippings that are stuck

to the screen.

Clean Blower

Service Interval: Yearly or before storage

Grass build up may cause problems with the impeller

when the unit is put back into operation.

1.

Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2.

Remove grass buildup from around the impeller

before placing it in storage.

18

Summary of Contents for 135-2604

Page 21: ...Notes 21 ...

Page 22: ...Notes 22 ...

Page 23: ...Service Record Date Description of Work Done Service Done By 23 ...