36

CAUTION

POTENTIAL HAZARD

♦

Raising the mower deck for service or maintenance

relying solely on mechanical or hydraulic jacks could be

dangerous.

WHAT CAN HAPPEN

♦

The mechanical or hydraulic jacks may not be enough

support or may malfunction allowing the unit to fall,

which could cause injury.

HOW TO AVOID THE HAZARD

♦

DO NOT rely solely on mechanical or hydraulic jacks for

support. Use adequate jack stands or equivalent

support.

a) This adjustment must be made with the drive wheels turning. First raise the

frame and block up so that drive wheels can rotate freely.

b) Remove the electrical connection from the seat safety switch, located directly

to the left of the seat switch assembly beside the hydraulic oil reservoir.

Temporarily

install a jumper wire across the terminals in the connector of

the wiring harness.

c) Run the unit at least 5 minutes with the drive levers at full forward speed to

bring hydraulic system oil up to operating temperature.

d) Unhook seat latch and tilt seat forward.

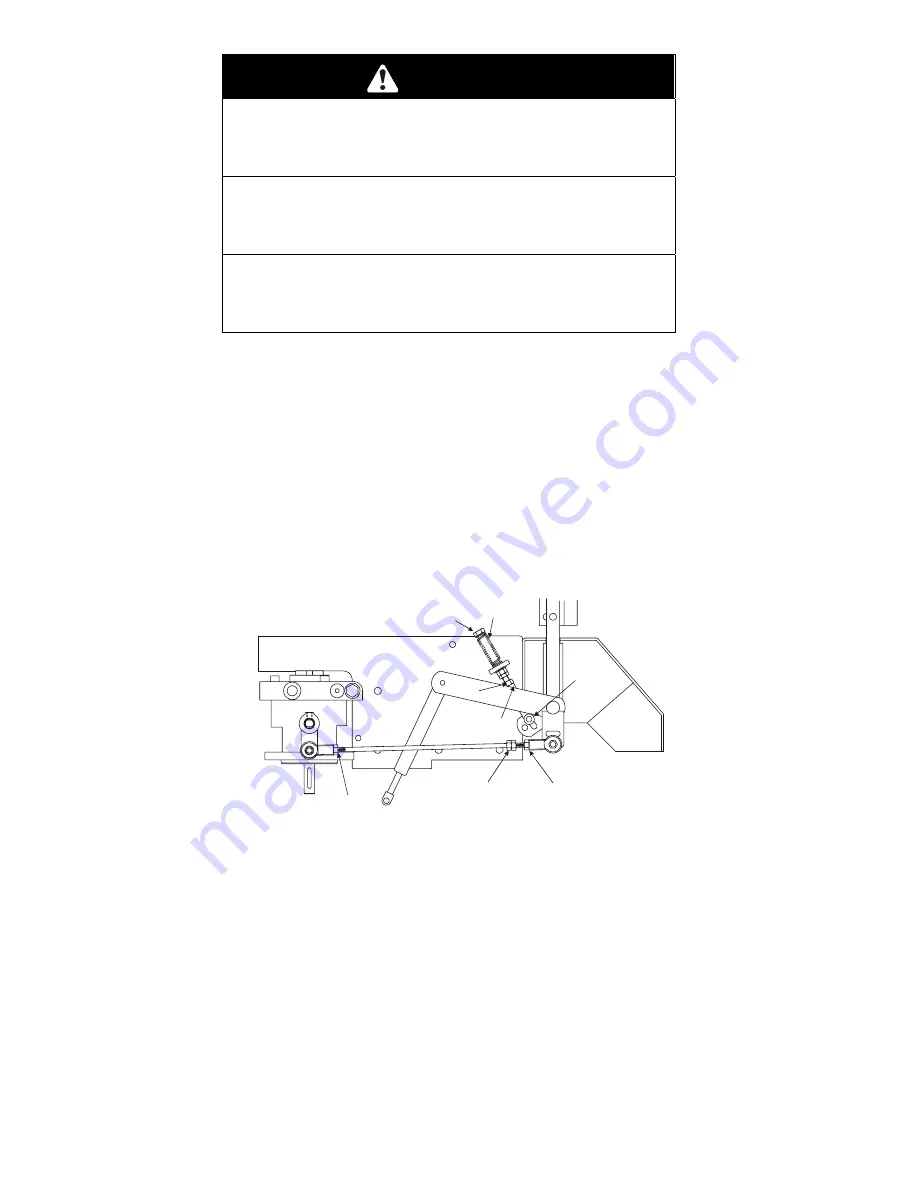

e) Loosen lock nuts from the ball joints at each end of the RH pump control

linkage (See Figure 15).

NOTE: The nuts to the rear of the unit on each rod have left-hand threads.

FIGURE 15

RH MOTION CONTROL ADJUSTMENT

f)

Start engine.

Brake must be engaged and motion control levers out to

start engine. Operator does not have to be in the seat because of the

jumper wire being used.

Run engine at full throttle and release brake.

g) The reverse indicator spring must be correct before the following

adjustments can be made. See Section 5.2.9.

h) Bring the RH motion control lever into the neutral position. Adjust RH pump

control rod length by rotating the double nuts on the rod in the appropriate

direction until the wheels slightly creep in reverse (See Figure 15). Move the

motion control lever to the reverse position and while applying slight pressure

to the lever, allow the reverse indicator spring to bring the levers back to

neutral. The wheel must stop turning or slightly creep in reverse.

NOTE: The motion control lever needs to be in neutral while making

any necessary adjustments.

TURN BOLT

HERE

LOOSEN HERE

(LEFTHAND THREAD)

END OF

SLOT

REVERSE

INDICATOR

TURN HERE

TO ADJUST

LOOSEN

HERE

LOOSEN HERE

(RIGHTHAND THREAD)

YOKE

Summary of Contents for Laser Z CT

Page 1: ...For Serial Nos 540 000 Higher Part No 103 9180 ...

Page 45: ...40 8 BRIGGS STRATTON ELECTRICAL DIAGRAM ...

Page 46: ...41 9 HYDRAULIC DIAGRAM ...

Page 48: ... 43 NOTES ...

Page 49: ... 44 NOTES ...

Page 50: ... 45 SERVICE RECORD Date Description of Work Done Service Done By ...

Page 51: ... 46 ...