Maintenance

Note:

Do Not add any type of tire liner or foam

fill material to the tires.

Excessive loads created by

foam filled tires may cause failures to the hydro drive

system, frame, and other components. Foam filling

tires will void the warranty.

Check Condition Of Belts

Service Interval: Every 50 hours

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Remove left and right belt shields on deck and lift

up floor pan to inspect deck drive belt.

3. Check under machine to inspect the pump drive

belt.

Note:

No adjustments are required for belt

tension.

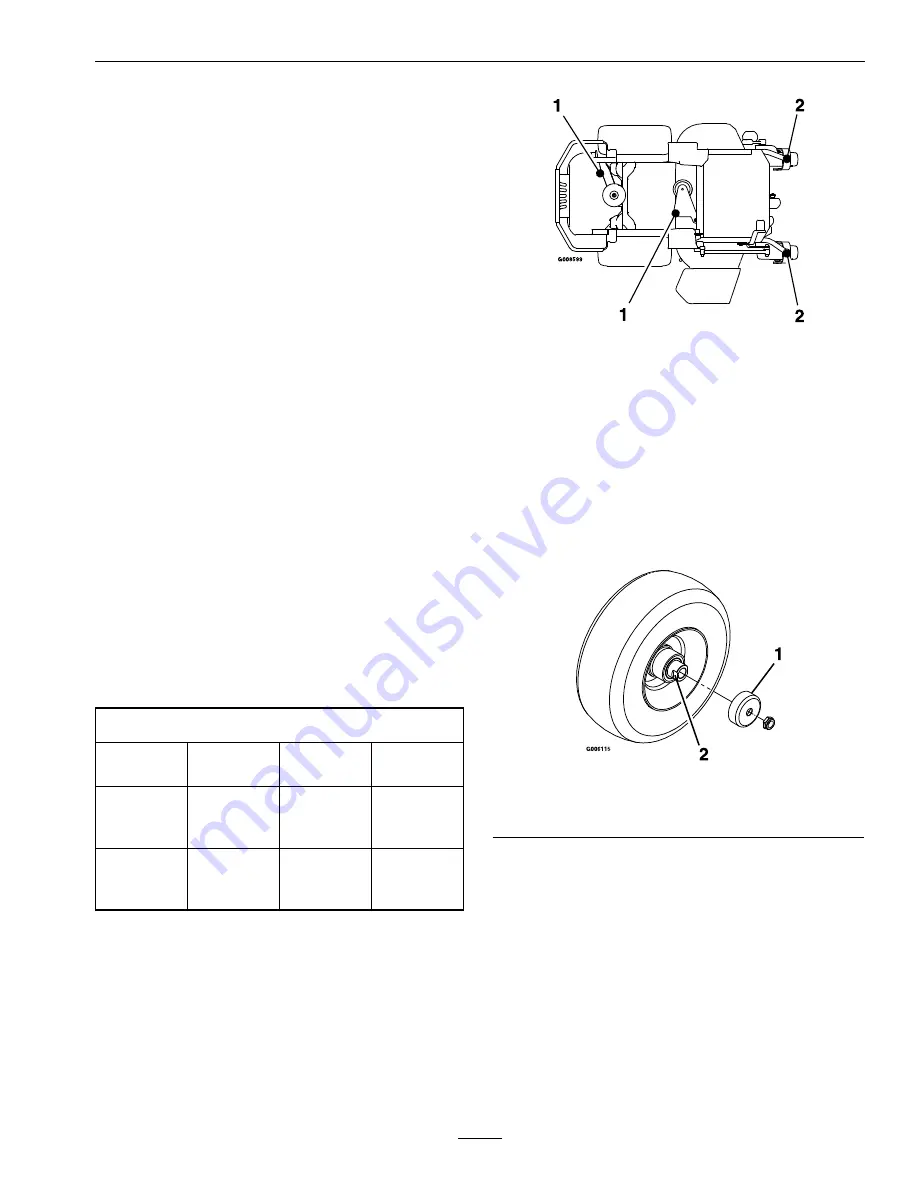

Lubricate Grease Fittings

Note:

See chart for service intervals.

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Lubricate fittings with one to two pumps of

NGLI grade #2 multi-purpose gun grease.

Refer to the following chart for fitting locations

and lubrication schedule.

Lubrication Chart

Fitting

Locations

Initial

Pumps

Number of

Places

Service

Interval

1. Deck and

Pump Idler

Pivots

1

2

Yearly

2. Front

Caster

Pivots

*0

2

*Yearly

* See step 3 for special lubrication instructions on

the front caster pivots.

3. Lubricate front caster pivots once a year. Remove

hex plug and cap. Thread grease zerk in hole and

pump with grease until it oozes out around top

bearing. Remove grease zerk and thread plug back

in. Place cap back on.

Lubricate Caster Wheel Hubs

Service Interval: As required

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

Figure 23

1.

Seal guard

2.

Spacer nut with wrench

flats

2. Remove caster wheel from caster forks.

3. Remove seal guards from the wheel hub.

4. Remove one of the spacer nuts from the axle

assembly in the caster wheel. Note that thread

locking adhesive has been applied to lock the

spacer nuts to the axle. Remove the axle (with

the other spacer nut still assembled to it) from

the wheel assembly.

5. Pry out seals, and inspect bearings for wear or

damage and replace if necessary.

6. Pack the bearings with a NGLI grade #1

multi-purpose grease.

35

Summary of Contents for Laser Z LZZ23KC486

Page 1: ...LAZER Z MODELS For Serial Nos 850 000 Higher Lazer Z LZZ Units Part No 4500 560 Rev B ...

Page 15: ...Safety PTO Switch Symbols 1 PTO disengage 2 PTO engage 109 7069 15 ...

Page 57: ...Schematics Hydraulic Diagram 57 ...

Page 59: ...Notes 59 ...

Page 60: ...Notes 60 ...

Page 61: ...Service Record Date Description of Work Done Service Done By 61 ...

Page 62: ...62 ...