Operation

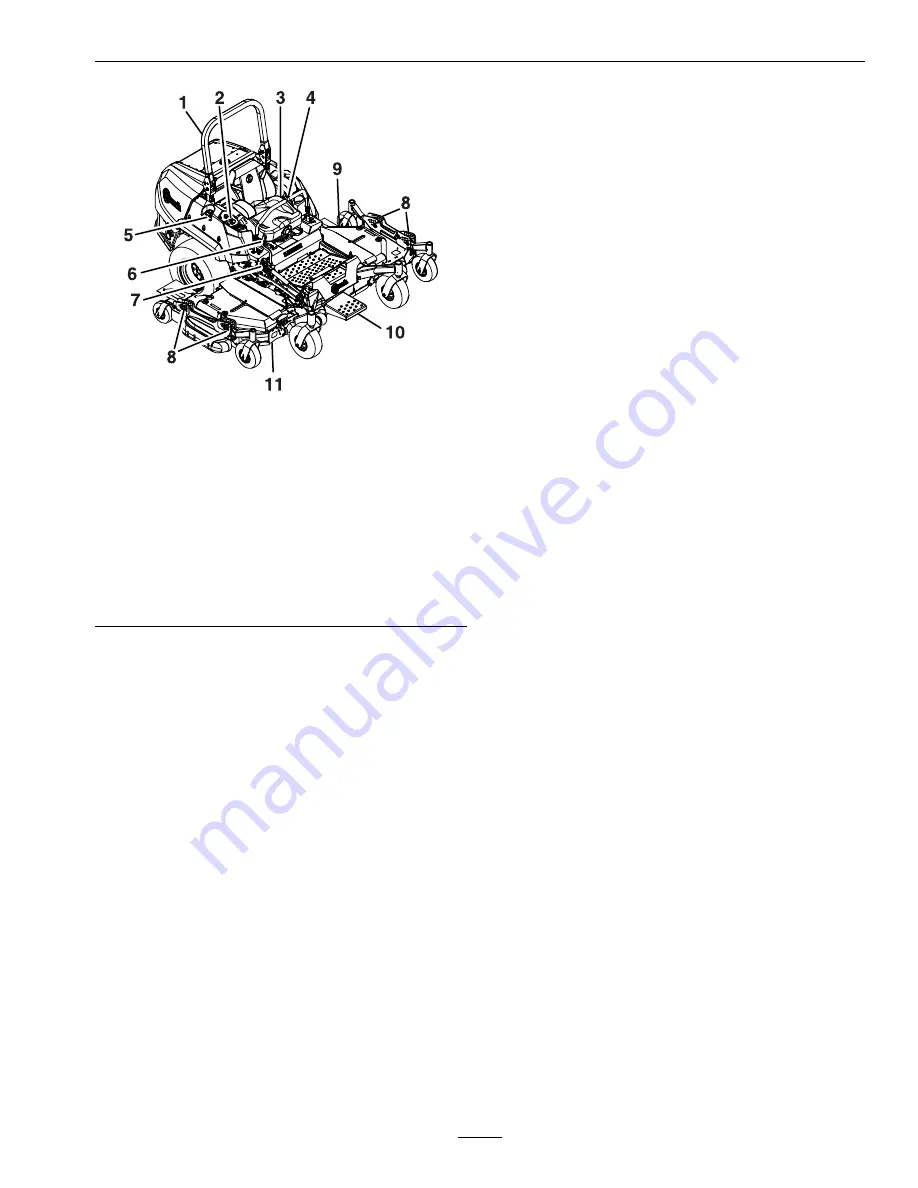

g237956

Figure 5

Model with 96 Inch Deck

1.

Rollover Protection

System (ROPS)

7.

Center deck height of cut

2.

Engine Controls (right

console)

8.

Wing deck height of cut

3.

Seat belt

9.

Left wing deck

4.

Motion control levers

10.

Step

5.

Fuel cap (both sides)

11.

Right wing deck

6.

Parking brake

Operation

Note:

Determine the left and right sides of the

machine from the normal operating position.

Controls

Motion Control Levers

The motion control levers located on each side of

the console control the forward and reverse motion

of the machine.

Moving the levers forward or backward turns

the wheel on the same side forward or reverse

respectively. Wheel speed is proportional to the

amount the lever is moved.

Moving the levers outward from the center position

into the T-slot locks them in the neutral position

(Figure 6).

Note:

When the motion control levers are in the

neutral position, a LCD indicator displays on the

message display.

25