Operation

B.

Insert the height adjustment pin into the hole

corresponding to the desired cutting height.

See the decal on the side of the deck lift plate

for cut heights.

6.

Adjust the side wing decks:

A.

Make sure the engine is off, the key has been

removed, and the deck wings are locked in

place.

B.

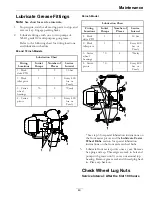

Unlock the cam locks located on the height of

cut channel on the wing deck (see Figure 17).

g239055

Figure 17

1.

Unlock cam lock

3.

Lynch pin

2.

Height of cut pin

C.

Remove the lynch pin from the height of cut

pin on both the front and rear channels.

D.

Move the wing deck to the appropriate height

and reinstall the height of cut pins and lynch

pins as shown in Figure 17.

E.

Lock the cam lock.

F.

Repeat for other wing deck.

7.

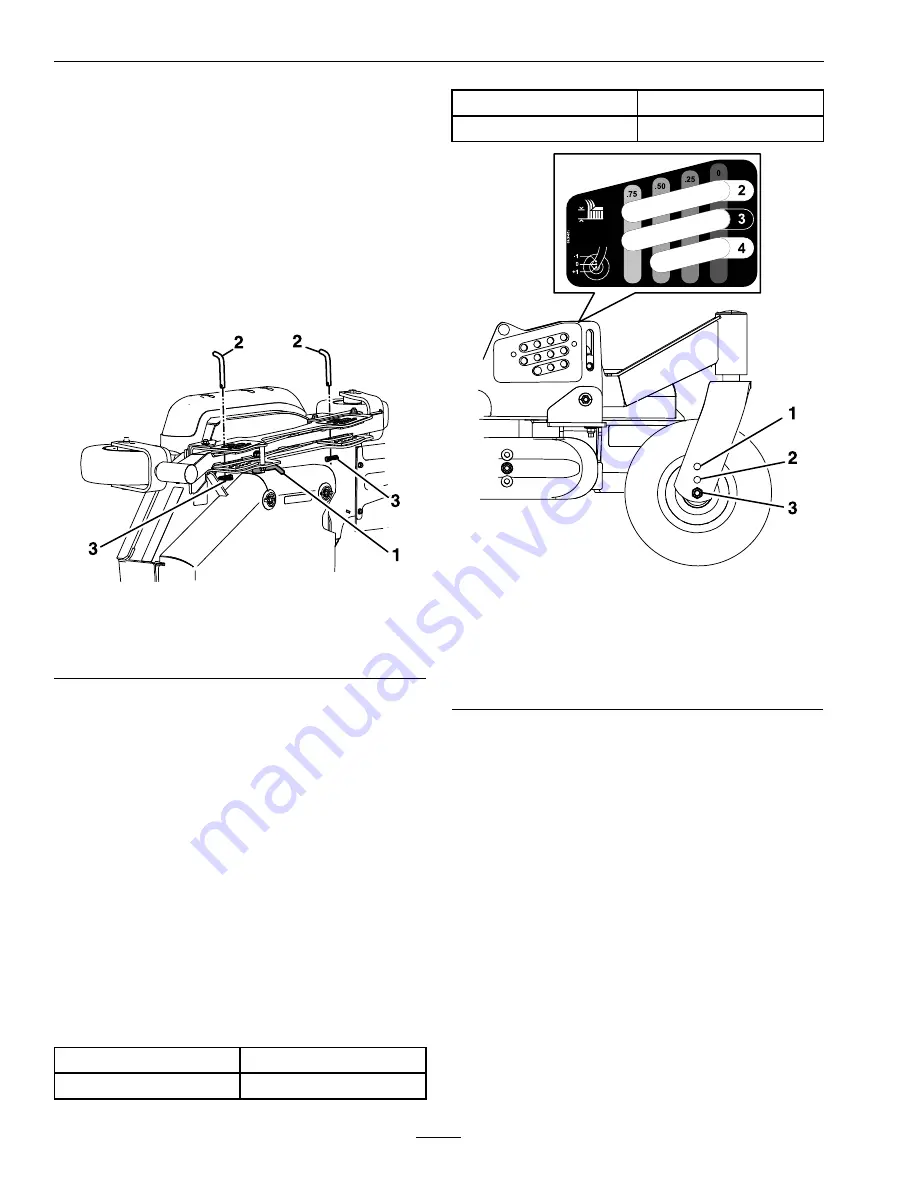

If additional height of cut range is desired, adjust

the front and rear gauge wheels on the wing deck:

A.

Remove the mounting hardware from the

gauge wheel.

B.

Adjust the front and rear gauge wheels to the

appropriate hole location (see the chart below

and Figure 18) and reinstall the mounting

hardware.

Hole Location

Height of Cut Range

Top hole (-1 on decal)

1–3.5 inches (25–89 mm)

Middle hole (0 on decal)

2–4.5 inches (51–114 mm)

Bottom hole (+1 on decal) 3–5.5 inches (76–140 mm)

g212253

Figure 18

Height of Cut Range

1.

Top hole (-1 on decal)

2.

Middle hole (0 on decal)

3.

Bottom hole (+1 on decal)

C.

Repeat for other wing deck.

Adjusting the Anti-Scalp Rollers

It is recommended to change the anti-scalp roller

position when the height of cut has changed.

1.

Stop the machine and move the motion control

levers outward to the neutral locked position.

2.

Disengage the PTO.

3.

Engage the park brake.

4.

Stop the engine, remove the key and wait for all

moving parts to stop.

5.

After adjusting the height of cut, adjust the

anti-scalp rollers by removing the mounting

hardware.

6.

Place the rollers in one of the positions shown

(Figure 19). Rollers will maintain 3/4 inch (19

34