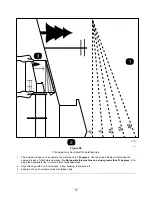

Maintenance

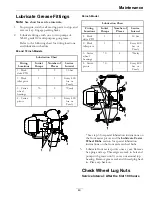

g228555

Figure 52

1.

Front location

5.

Spring

2.

Rear location

6.

Link assembly

3.

3 1/4 inches (8.3 cm)

7.

Length

4.

Gap

11.

Disengage the park brake, the lever should be in

the down position. Turn the wheel hub by hand

in both directions relative to the caliper; the wheel

hub should move freely.

12.

If a gap is needed or the wheel hub does not

move freely:

A.

Disengage the park brake.

B.

Disconnect and fine-tune the rear linkage

assembly:

•

Shorten the link to create a gap.

•

Lengthen the link to allow wheel hub

movement.

C.

Reconnect the rear linkage assembly.

13.

Engage the parking brake and check the gap.

14.

Repeat steps 11 through 14 until a visible gap is

achieved and the wheel hub rotates freely. Repeat

for the brake on the right side.

Note:

The brake should fully disengage when

the brake is in the “released” position.

15.

Rotate the drive wheel release handle to the

“operating” position. Refer to the

Drive Wheel

Release Valves

section in Operation.

16.

Install the rear tires and torque lug nuts to 85-105

ft-lb (115-142 N-m).

17.

Remove jack stands.

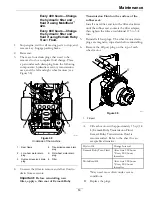

Motion Control Linkage

Adjustment

WARNING

Engine must be running and drive wheels must

be turning so motion control adjustment can be

performed. Contact with moving parts or hot

surfaces may cause personal injury.

Keep fingers, hands, and clothing clear of

rotating components and hot surfaces.

CAUTION

Raising the mower deck for service or

maintenance relying solely on mechanical

or hydraulic jacks could be dangerous. The

mechanical or hydraulic jacks may not be enough

support or may malfunction allowing the unit to

fall, which could cause injury.

Do Not rely solely on mechanical or hydraulic

jacks for support. Use adequate jack stands or

equivalent support.

1.

This adjustment must be made with the drive

wheels turning. First raise the rear of machine

up and support with jack stands (or equivalent

support) just high enough to allow the drive

wheels to rotate freely.

2.

Unhook seat latch and tilt seat forward.

3.

Remove the electrical connection from the seat

safety switch, located directly to the left of the seat

switch assembly beside the hydraulic oil reservoir.

Temporarily

install a jumper wire across the

terminals in the connector of the main wiring

harness.

4.

Run the unit at least 5 minutes with the drive

levers at full forward speed to bring hydraulic

system oil up to operating temperature.

62