Page 2 of 13

109-4195 Rev. A

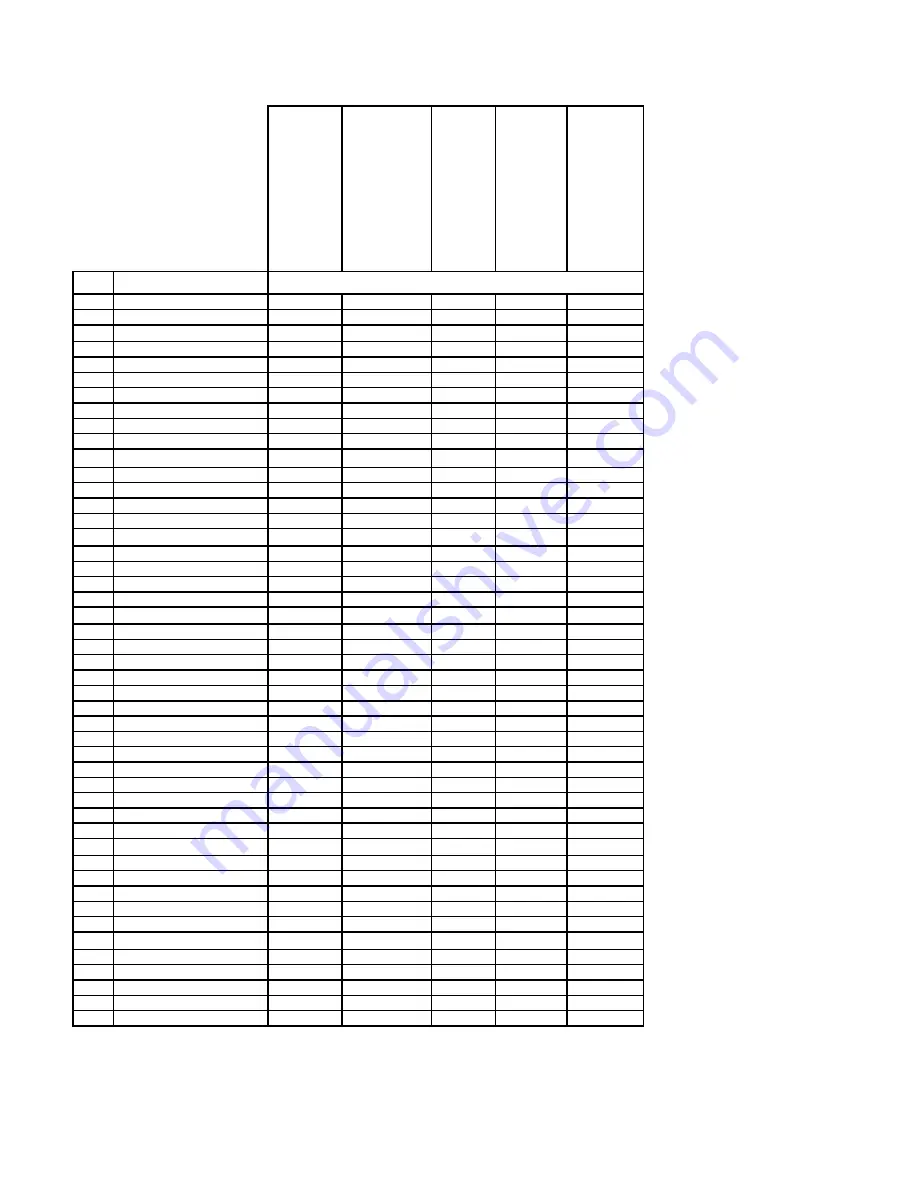

1. Assembly Instructions

60&72 LZ an

d AS

352,

000-509,

999

Al

l X

S

, X

P

Bel

o

w

600,

000

&

60 AS

510,

000

& Hi

gher

60 & 72 L

Z

510,

000-599,

999

Al

l

LZ 600

,000 & Hi

gher

wi

th Tr

it

on

deck

Al

l

X

S

Ai

r Co

o

led

600,

000 & Hi

g

h

er

A

ll

XS

L

iq.

C

o

o

le

d

600,

000 & Hi

g

h

er

Item Description

Qty

1 Hopper

Assembly

1

1

1

1

1

2 Upper

Tube

1

1

1

1

1

3 Lower

Tube

1

1

1

1

1

4 #10-24

CRPH

Screw

3

3

3

3

3

5 #10-24

Nyloc

Nut

3

3

3

3

3

6 #10

Flat

Washer

3

3

3

3

3

7 Handle

Assembly

1

1

1

1

1

8 Blower

Assembly

1

1

1

1

1

9 Bagger

Mount

Weldment

1

1

1

1

1

10 Belt

Cover

1

1

1

1

1

11 Caster

Weight

2

2

2

2

2

12 Jackshaft

1

1

1

1

1

13 Blower

Drive

Belt

1

1

1

1

1

14

Frame Bracket RH

1

15

Frame Bracket LH

1

16

Frame Bracket

2

2

2

2

17

Mount Spacer

2

2

4

4

18 Mount

Pin

Weldment

1

1

1

1

1

19 Clevis

Pin

4

4

4

4

4

20

Hair Pin (large)

4

4

4

4

4

21

Chute Pivot Pin

1

1

1

1

1

22

Hair Pin (small)

1

1

1

1

1

23

3/8-16 x 1.00 Hex Screw

13

16

16

12

12

24 3/8

Whizlock

Nut

16

19

19

15

15

25

3/8 Spring Disk Washer

13

16

16

16

16

26 Handle

Mount

Weldment

1

27

Belt Shield Stud

1

1

1

1

1

28

3/8-16 x .75 Hex Screw

3

3

3

3

3

29

Belt Cover Spacer

1

-60 only

1

-60 only

1

-60 only

1

-60 only

1

-60 only

30

7/16 Spring Disk Washer

2-

60 only

2

-60 only

2

-60 only

2

-60 only

2

-60 only

31 Weight

Bracket

2

2

2

2

2

32 3/8-16

Square

Head

Bolt

4

4

4

4

4

33 Weight

Plate

4

4

4

34

5/16-18 x 1.75 Hex Screw

4

4

4

5/16-18 x 1.5 Hex Screw

4

4

4

35

5/16 Flat Washer

4

4

4

36

5/16-18 Whizlock nut

4

4

4

37

Nut, Nyloc Thin

2

38

Washer

1

1

1

39

3/8-16 x 1.25 Hex Screw

4

4

4

40 Plug

1

1

1

1

1

41

Weight Plate Weldment

1

1

42

Weight Mounting Plate

2

2

43

Hairpin

2

2

44

Drill Template

1

1

1

45

Spacer

6

46 Deflector

plate

1

1

1

Items 21, 22, 29, 30, 44, 45, & 46 not shown

See Figure 12 for installation of 29 & 30

See Figure 5 for 45

See Figure 11 for installation of 46