Page 6 of 13

109-4195 Rev. A

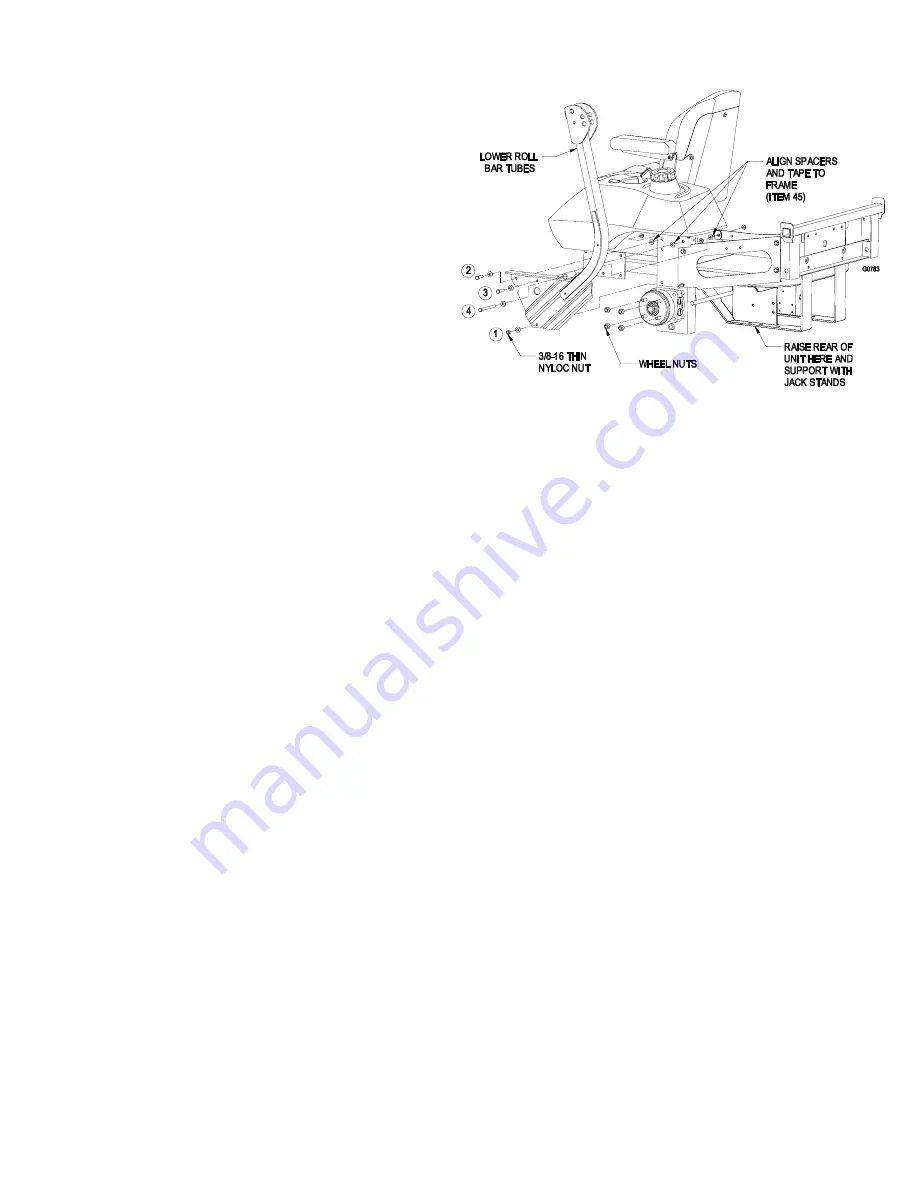

Units without ROPS skip to Step 28:

14. Align three spacers (Item 45) on each side and

tape with masking tape to the rear frame as shown

in Figure 5.

15. Align lower roll bar tubes along wheel motor

channels as shown in Figure 5.

16.

LOOSELY

install the lower roll bar hardware to the

tubes in the following order (Reference Figure 5 for

alignment and installation instructions below):

17. Discard the 3/8-16 regular nyloc nut provided with

the Lazer Z unit or ROPS kit and replace with the

3/8-16 thin nyloc nut (Item 37) provided with this

Ultra Vac.

18. Install the 3/8-16 thin nyloc nut (Item 37) and a

spring disk washer to the bolt protruding from the

wheel motor channel as shown.

NOTE:

Be sure the spring disk washer cone is

installed towards the nyloc nut.

Units with SN 399,999 and lower

require use of a

3/8-16 x 1 1/2 screw, spring disk washer and

whizlock nut. These items are included with

ROPS kit number FRPSLZ.

NOTE:

On 60” units, the lower bolt on the wheel

channel is best installed by positioning the nut

behind the hole using a deep socket and turning

the bolt through the hole into the nut.

19. Install one 3/8-16 x 1 1/2 hex capscrew, spring

disk washer and 3/8-16 whizlock nut to the top

front hole as shown (it will be necessary to push

the capscrew through the masking tape applied in

step 14).

20. Install one 3/8-16 x 1 1/2 hex capscrew, spring

disk washer and 3/8-16 whizlock nut to the top

rear hole as shown (it will be necessary to push

the capscrew through the masking tape applied in

step 14).

Install one 3/8-16 x 4 1/2 hex capscrew, spring

disk washer and 3/8-16 whizlock nut through the

top tube as shown (it will be necessary to push

the capscrew through the masking tape applied in

step 14).

NOTE

: Be sure the spring disk washer cone is

installed towards the head of all capscrews.

FIGURE 5

For All Lazer Z XP, XS, and Lazer Z Units with

a ROPS installed:

21. Install the upper u-shaped section of the roll

bar. (Reference Figure 6 for alignment and

installation instructions below):

22. Locate the latch pin assemblies (pin and

hairpin connected with a lanyard).

23. Install a 1/2-13 x 3 1/4 capscrew in the washer

on the lanyard of each pin assembly.

NOTE

: Make sure the bent tab in the washer

points toward the head of the capscrew.

24. Lightly oil the inside surfaces of the ear-shaped

plates at the upper end of the lower roll bar

tubes.

25. Locate the upper u-shaped section of the roll

bar. Install the upper roll bar section using one

1/2-13 x 3 1/4 capscrew (from step 23) and one

1/2-13 hex flange lock nut on each side. Do

not over tighten. Make sure upper roll bar can

pivot freely.

NOTES

:

♦

Make sure the capscrew and nuts are

installed with the nut to the inside of the

roll bar.

♦

Make sure the tab on the lanyard washer

is installed as shown and points toward

the front of the unit.

26. Raise the roll bar into the upright position and

secure with the latch pin assemblies on each

side. Install latch pin from outer surface of roll

bar assembly and secure with the hairpin to

the inside.

27. Tighten the front knobs against the upper roll

bar ends.