23

4.1.11 Check hydraulic oil level:

Service Interval:

40 hr.

a) Stop engine and wait for all moving parts to stop.

b) Clean area around hydraulic reservoir cap and remove cap.

c)

Oil level should be to the top of the baffle inside the tank. If not add oil.

Use

only Mobil 1 15W-50 synthetic motor oil.

Replace hydraulic reservoir cap

and tighten until snug.

Do not overtighten.

NOTE: The baffle is labeled “HOT” and “COLD”. The oil level varies with the

temperature of the oil. The “HOT” level shows the level of oil when it is at

225°F (107°C). The “COLD” level shows the level of the oil when it is at 75°F

(24°C). Fill to the appropriate level depending upon the temperature of the oil.

For example: If the oil is about 150° F (65°C), fill to halfway between the “HOT”

and “COLD” levels. If the oil is at room temperature (about 75° F (24°C)), fill

only to the “COLD” level.

4.1.12 Check tire pressures:

Service

Interval:

40

hrs.

a) Stop engine, wait for all moving parts to stop, and remove key.

b) Check tire pressure in all four tires.

c) Inflate caster tires to 16 psi (1100 kPa).

d) Inflate drive tires to 13 psi (90 kPa).

NOTE: Do not add any type of tire liner or foam fill material to the tires.

Excessive loads created by foam filled tires may cause failures to the hydro drive

system, frame and other components. Foam filling tires will void the warranty.

4.1.13 Check condition of belts:

Service Interval: 40 hrs.

a)

Stop engine, wait for all moving parts to stop, and remove key.

b)

Check under engine deck to check pump drive belt.

c)

Remove left and right belt shields on deck and lift up floor pan to inspect

deck drive belt.

d)

See Sections 4.2.3 and 4.2.4, for belt adjustment.

4.1.14 Lubricate grease fittings:

Service Interval: Refer to chart.

a)

Stop engine, wait for all moving parts to stop, and remove key.

b)

Lubricate fittings with one to two pumps of NGLI grade #2 multi-purpose

gun grease.

Refer to the following chart for fitting locations and lubrication schedule.

Summary of Contents for Lazer ZCT

Page 1: ...For Serial Nos 600 000 Higher Part No 109 2279 Rev B ...

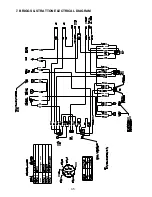

Page 40: ...35 7 BRIGGS STRATTON ELECTRICAL DIAGRAM ...

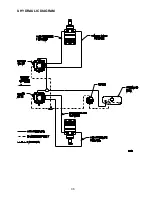

Page 41: ...36 8 HYDRAULIC DIAGRAM ...

Page 44: ... 39 NOTES ...

Page 45: ... 40 NOTES ...

Page 46: ... 41 SERVICE RECORD Date Description of Work Done Service Done By ...

Page 47: ... 42 ...