27

4.1.25

Fuel

Tank – mounting hardware specification.

When installing the nuts onto the fuel tank studs, fully tighten the nyloc nut and

back off 1/2 turn. This allows for normal fuel tank expansion and contraction with

changes in temperature and fuel levels.

4.1.26 Thread locking adhesives such as “Loctite 242” or “Fel-Pro, Pro-Lock Nut Type”

are used on the following fasteners:

a)

Pump drive sheave setscrews.

b)

Square head setscrews on hydro pump control arms.

c)

Clutch retaining bolt in the end of engine crankshaft.

d)

Caster wheel spacer nuts.

e)

Fuel tank bulk head fitting nuts.

f)

Cutter housing spindle nut

Adhesives such as “Loctite RC/609 or RC/680” or “Fel-Pro Pro-Lock Retaining I

or Retaining II” are used on the following:

a) Fuel tank studs where studs are inserted into tank.

4.1.27 Mobil HTS grease (or food-grade antisieze) is used in the following locations:

a)

Between the cutter housing spindle and bearings.

b)

Between the cutter housing spindle and sheave.

c)

Under top cutter housing bearing guard.

4.1.28

Dielectric

grease is used on all blade type electrical connections to prevent

corrosion and loss of contact.

4.2

ADJUSTMENTS

IMPORTANT: Disengage PTO, shut off engine, wait for all moving parts to stop,

and remove key before servicing, cleaning or making adjustments to the unit.

4.2.1

Cutting Height Adjustment.

a)

Stop machine and move drive levers out to neutral lock position.

b)

Disengage

PTO.

c)

Raise the deck lever to the transport position (also the 4.5” (11.4 cm)

cutting height position). See Figure 5.

NOTE: When changing cutting height positions, always come to a

complete stop and disengage the PTO.

FIGURE 5

CUTTING HEIGHT POSITION

d)

Insert height adjustment pin into hole corresponding to desired cutting

height and install hairpin cotter. See decal on deck lift plate.

e)

Move lever out of transport (or 4.5” (11.4 cm) cutting height) position and

down onto height

adjustment

pin

to

mow

at

selected height.

Summary of Contents for Lazer ZCT

Page 1: ...For Serial Nos 600 000 Higher Part No 109 2279 Rev B ...

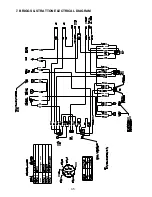

Page 40: ...35 7 BRIGGS STRATTON ELECTRICAL DIAGRAM ...

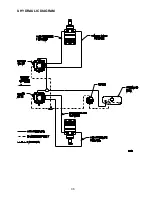

Page 41: ...36 8 HYDRAULIC DIAGRAM ...

Page 44: ... 39 NOTES ...

Page 45: ... 40 NOTES ...

Page 46: ... 41 SERVICE RECORD Date Description of Work Done Service Done By ...

Page 47: ... 42 ...