- 29 -

5.2.5

Adjust Seat Switch

a) If necessary, adjust the seat actuator rod length to where the machine will

shut off when the operator raises off the seat (with

brake disengaged

or

PTO engaged

) but will continue to run with operator in seat (a slight shift in

weight should not shut machine off).

NOTE: To prevent the engine from cutting out when operating over

rough ground, the unit is equipped with a time-delayed seat switch.

When the operator rises off the seat with either the brake disengaged or

the PTO engaged, the engine should stop after 1/2 second has elapsed.

b) To adjust seat switch actuator rod length, loosen lock nut on bottom of the

actuator rod (5/16 x 5 1/2” bolt) and adjust the nuts to move the actuator

plate/washer up or down on the rod, then retighten.

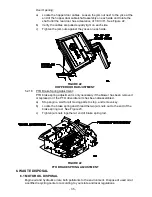

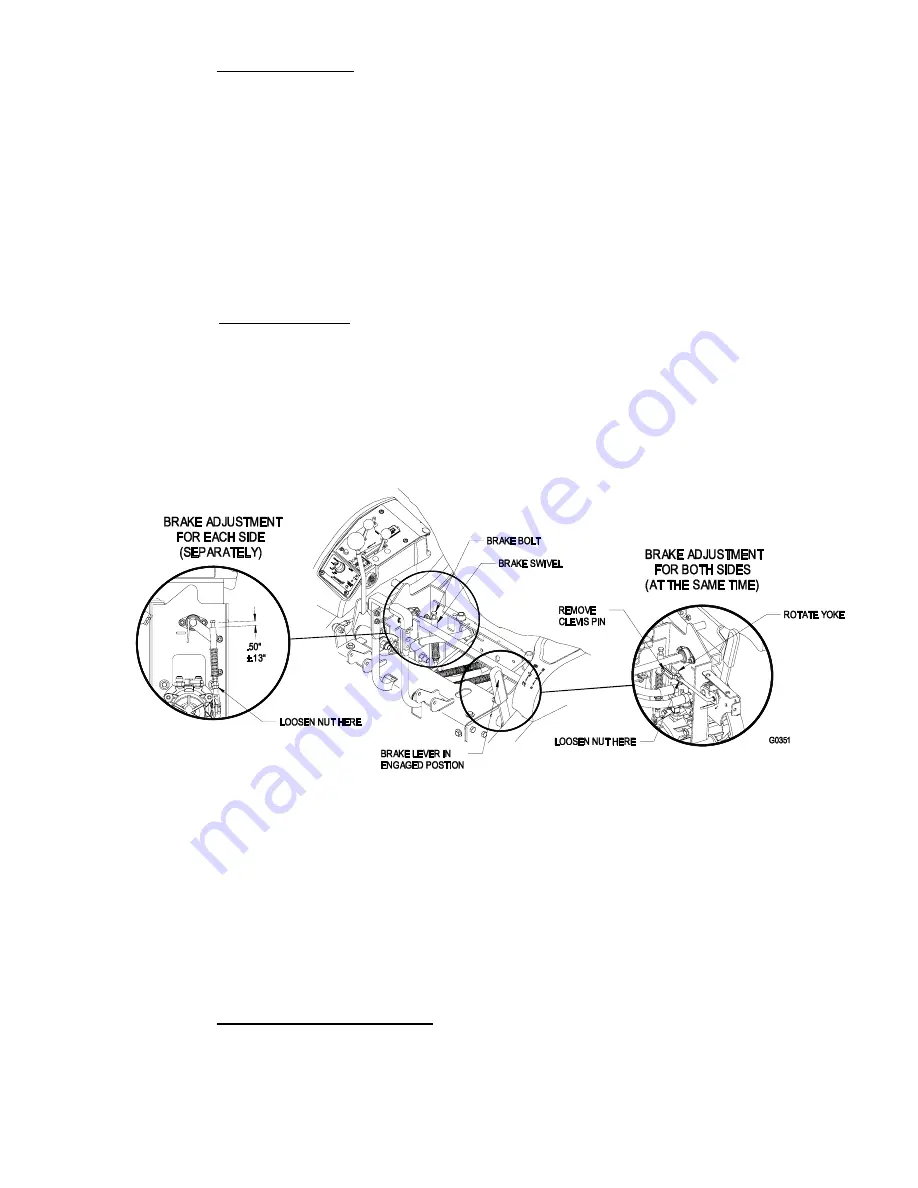

5.2.6 Brake

Adjustment.

Check to make sure each brake is adjusted properly.

a) Pull the brake lever up and back to the engaged position.

b) A gap must exist between the bottom of the brake bolt head and the top surface

of the brake swivel as shown in Figure 12. If a gap does not exist, adjust the

linkage to a maximum gap of 0.5” ± 0.13” (1.3 cm ± 0.33 cm) as shown.

c) The brakes on both sides can be simultaneously adjusted by lengthening or

shortening the linkage shown in Figure 12.

FIGURE 12

BRAKE BOLT ADJUSTMENT

d) If individual adjustment is necessary, loosen the jam nut on the brake bolt that

is against the clevis connected to the brake arm on the wheel motor. Turn the

brake bolt to achieve proper adjustment.

e) Tighten the jam nut against the clevis.

f)

Repeat for other side of unit.

g) Engage and disengage the brakes to check for proper engagement and

disengagement. Readjust if necessary. When the brakes are disengaged,

there should be free play in the brake linkage with no dragging in the brakes.

5.2.7

Adjust Throttle Lever Tension.

a) Stop engine, wait for all moving parts to stop, and remove key.

b) Tension in throttle lever can be adjusted by adjusting the tightness of the

lever pivot bolt, which is located under the console. See Figure 13.

Summary of Contents for Navigator NAV20KC

Page 1: ...Part No 103 8573 Rev B For Serial Nos 510 000 Higher ...

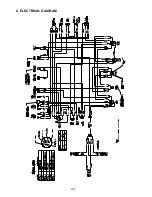

Page 44: ... 39 8 ELECTRICAL DIAGRAM ...

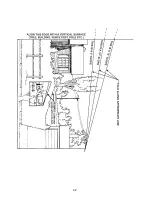

Page 45: ... 40 9 HYDRAULIC DIAGRAM ...

Page 47: ...42 ...