Maintenance

Important:

Replace the foam element if it

is torn or worn.

3.

Lightly oil the foam element using new engine oil

and squeeze out any excess oil.

Paper Element:

1.

Lightly tap the element on a flat surface to remove

dust and dirt.

2.

Inspect the element for tears, an oily film, and

damage to the seal.

Important:

Do not clean the paper element

with pressurized air or liquids, such as

solvent, gas, or kerosene. Replace the paper

element if it is damaged or cannot be cleaned

thoroughly.

3.

Replace the paper element if it is damaged.

Installing the Air Cleaner

1.

Install the foam pre-cleaner element over the

paper element.

Note:

Ensure that you do not damage the

elements.

2.

Install the air cleaner elements onto the air cleaner

base.

3.

Install the cover and secure it with the retaining

clamps (see Figure 41).

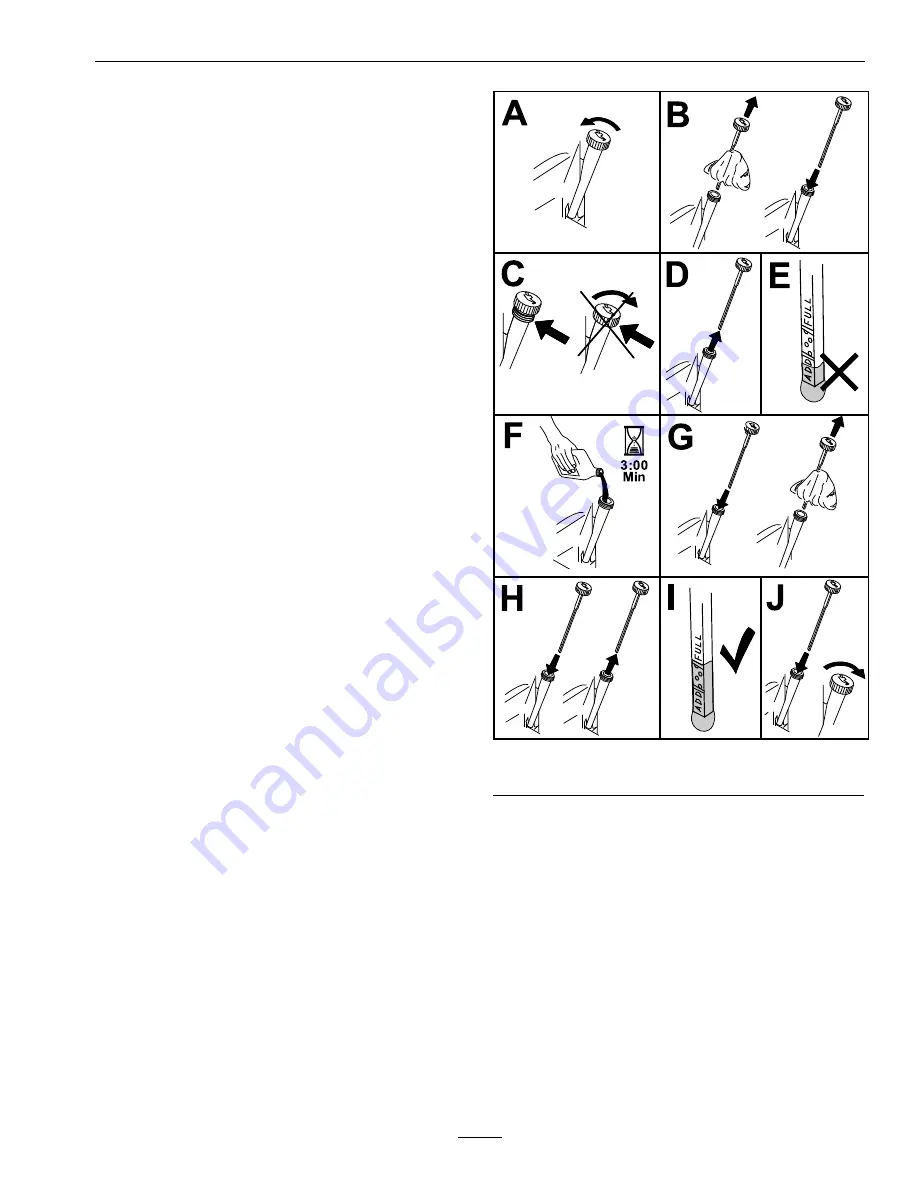

Checking the Engine Oil Level

Service Interval: Before each use or daily

Important:

Do not overfill the crankcase with oil

and run the engine; engine damage may result.

1.

Park machine on level ground, move the motion

control levers out to engage the parking brake,

disengage the blade control switch, stop engine,

and remove key. Wait for all moving parts to stop

before leaving the operator’s position.

2.

Make sure the engine is stopped, level, and is cool

so the oil has had time to drain into the sump.

3.

To keep dirt, grass clippings, etc., out of

the engine, clean the area around the oil fill

cap/dipstick before removing it.

4.

Check the engine oil level.

g336929

Figure 43

5.

If the level is low, wipe off the area around the oil

fill cap, remove cap/dipstick and add oil to the

“FULL” mark on the dipstick. Exmark 4-Cycle

Premium Engine Oil is recommended; refer to

the following information for an appropriate API

rating and viscosity. Always check the level with

the dipstick before adding more oil.

Do Not

overfill.

•

Crankcase Capacity: 1.9 L (64 oz) with oil

filter

•

Recommended Oil Type: Exmark 4-Cycle

Premium Engine Oil

– API service SJ or higher

43

Summary of Contents for QUEST 346

Page 1: ...QUEST For Serial Nos 408 644 346 Higher Part No 4505 333 Rev A ...

Page 65: ...Schematics Schematics Electrical Logic Schematic g330623 65 ...

Page 67: ...Notes 67 ...

Page 68: ...Notes 68 ...

Page 69: ...Service Record Date Description of Work Done Service Done By 69 ...

Page 70: ...70 ...