Maintenance

g006780

Figure 20

1.

Install bushing in blade prior to installing bushing in

spindle.

B.

Install bushing/blade assembly into spindle.

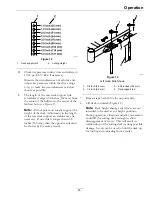

g014914

Figure 21

1.

Use wrench here for blade installation. This nut has

been torqued to 130-160 ft-lb (176–217 N-m)

2.

Torque to 50-60 ft-lb (68-81 N-m) Apply lubricant to

threads as needed to prevent seizing. Copper-based

anti-seize preferable. Grease acceptable substitute.

C.

Apply lubricant to threads of blade bolt as

needed to prevent seizing. Copper-based

anti-seize preferable. Grease acceptable

substitute. Install blade bolt finger tight. Place

wrench on the top spindle nut then torque the

blade bolts to 50-60 ft-lb (68-81 N-m).

WARNING

Incorrect installation of the blade or

components used to retain the blade can

be dangerous. Failure to use all original

components and assembled as shown could

allow a blade or blade component to be

thrown out from under the deck resulting in

serious personal injury or death.

Always install the original Exmark blades,

blade bushings, and blade bolts as shown.

31