- 24 -

6.1.11 Check tire pressures:

Service

Interval: 40 hrs.

a)

Stop engine, wait for all moving parts to stop, and remove key.

b)

Inflate tires to pressures specified in Section 2.8 (Specifications).

c)

See Section 8.1 for further information.

NOTE: Do not add any type of tire liner or foam fill material to the tires.

Excessive loads created by foam filled tires may cause failures to the hydro drive

system, frame, and other components. Foam filling tires will void the warranty.

6.1.12 Check battery charge:

Service

Interval: Monthly

Allowing batteries to stand for an extended period of time without recharging

them will result in reduced performance and service life. To preserve

optimum battery performance and life, recharge batteries in storage when

the open circuit voltage drops to 12.4 volts.

Note: To prevent damage due to freezing, battery should be fully charged

before putting away for winter storage.

a)

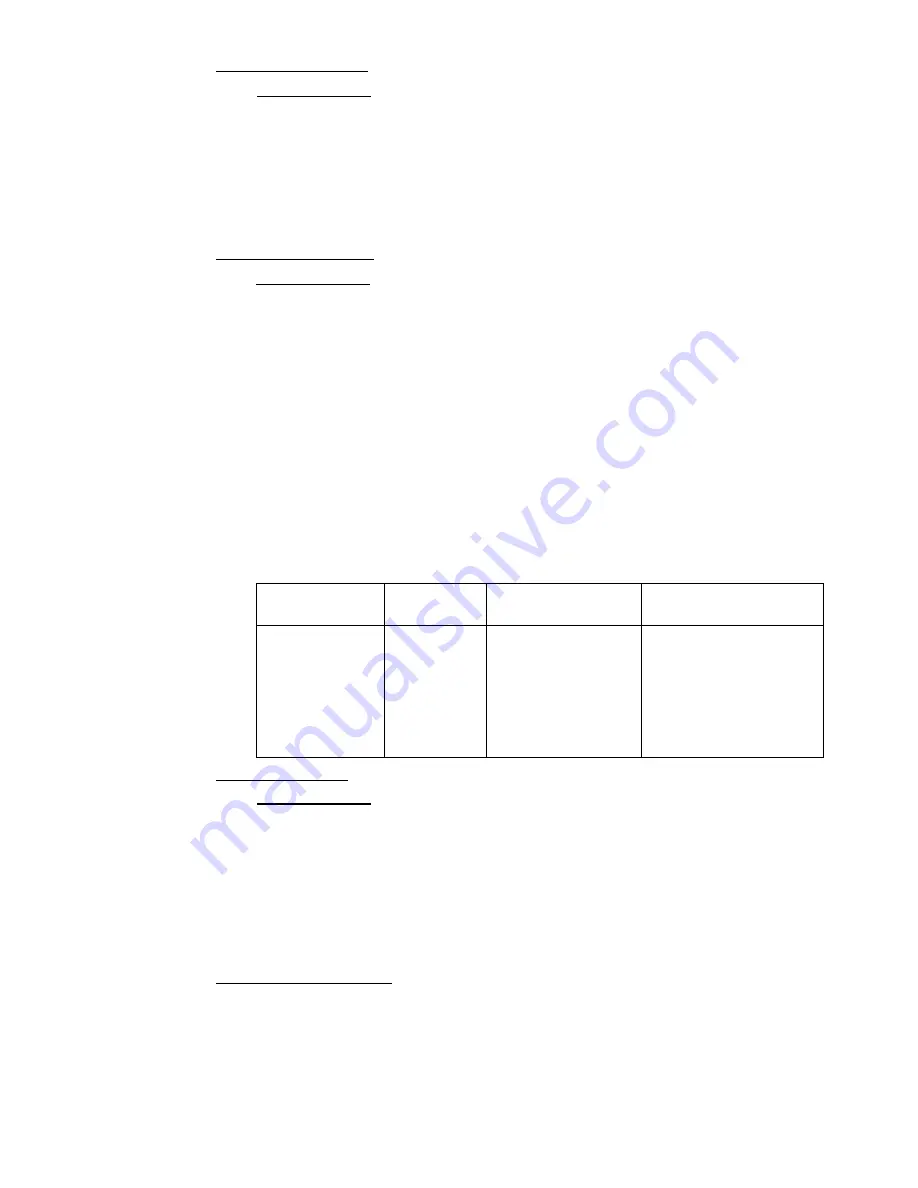

Check the voltage of the battery with a digital voltmeter. Locate the voltage

reading of the battery in the table below and charge the battery for the

recommended time interval to bring the charge up to a full charge of 12.6

volts or greater.

IMPORTANT:

Make sure the negative battery cables are disconnected

and the battery charger used for charging the battery has an output of 16

volts and 7 amps or less to avoid damaging the battery (see chart below for

recommended charger settings).

Voltage

Reading

Percent

Charge

Maximum

Charger Settings

Charging Interval

12.6 or greater 100%

16 volts/7 amps

No Charging Required

12.4 – 12.6

75 – 100%

16 volts/7 amps

30 Minutes

12.2 – 12.4

50 – 75%

16 volts/7 amps

1 Hour

12.0 – 12.2

25 – 50%

14.4 volts/4 amps

2 Hours

11.7 – 12.0

0 – 25%

14.4 volts/4 amps

3 Hours

11.7 or less

0%

14.4 volts/2 amps

6 Hours or More

6.1.13 Inspect Belt Wear:

Service

Interval: 40 hrs.

a)

Stop engine, wait for all moving parts to stop, and remove key.

b)

Remove the three mower deck belt shields to check mower primary and

secondary belt condition.

c)

Look under engine deck to check the transmission drive belt condition.

d)

Check all idler arms to be sure they pivot freely.

Note: Be sure to check idler on transmission drive belt. Disassemble, clean and

grease pivot bushing if necessary.

6.1.14 Lubricate grease fittings.

a)

Stop engine, wait for all moving parts to stop, and remove key.

b)

Lubricate fittings with one to two pumps NGLI grade #2 multi-purpose gun

grease

.

Refer to the following chart for fitting locations and lubrication schedule.

Summary of Contents for Turf Ranger TR23KC

Page 44: ... 38 NOTES ...

Page 45: ... 38 NOTES ...

Page 46: ... 39 SERVICE RECORD Date Description of Work Done Service Done By ...

Page 47: ... 40 ...