2. Insert the end of the linkage opposite the yoke into

the end of the speed control lever located underneath

the handle console from the right hand side and

fasten with a hairpin from the bolt bag.

3. Connect the lower end of the speed control linkage

to the speed control crank located at the top rear of

the fuel tank support. Secure with a clevis pin and

3/32 x 1/2 inch cotter pin.

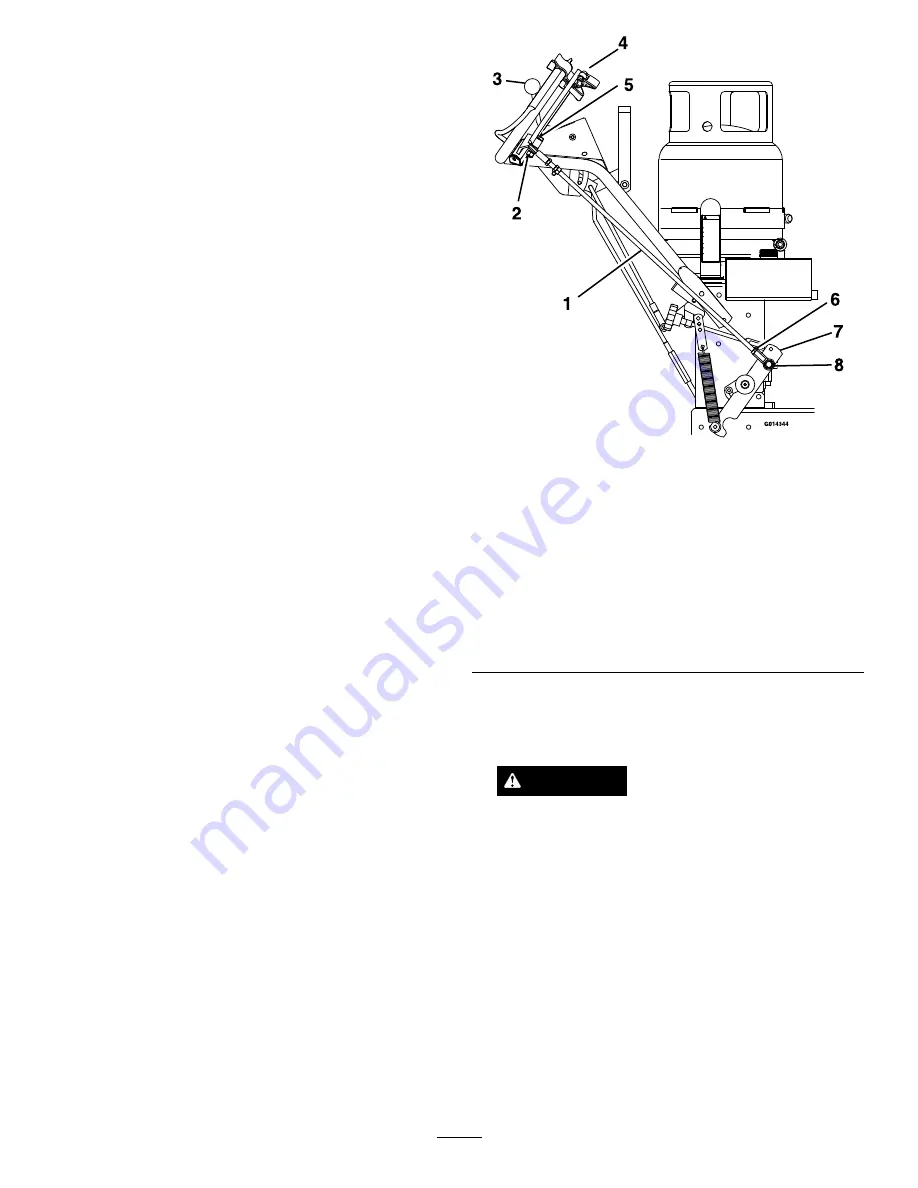

Installing the Wheel Drive

Linkages

1. Position the speed control lever in neutral.

2. Position the drive levers in neutral and engage the

neutral lock latches (Figure 6).

3. Thread a 3/8-24 inch LH jam nut, from the bolt bag,

onto the lower end of each drive lever linkage.

4. Identify the lower ball joints installed on the hydro

control arm weldments. Thread the lower end of

each drive lever linkage into the lower ball joint until

the hole in upper ball joint aligns with hole in drive

lever.

5. Install a 5/16-18 x 1 3/4 inch hex cap screw and

a 5/8-18 inch nyloc nut on each side and tighten.

This will give an approximate setting for drive lever

linkages.

Figure 6

Right Hand Side of Unit Shown

1.

Drive lever linkage

2.

5/16-18 inch nyloc nut

3.

Speed control lever in neutral

4.

Drive levers in neutral

5.

5/16-18 x 1 3/4 inch hex capscrew

6.

3/8-24 inch LH jam nut

7.

Hydro control arm weldment

8.

Lower ball joint

Adjusting the Drive Lever Linkages

1. Raise the rear of machine off of the ground.

CAUTION

Raising the rear of the unit for assembly relying

solely on mechanical or hydraulic jacks could be

dangerous. The mechanical or hydraulic jacks

may not be enough support or may malfunction

allowing the unit to fall, which could cause

injury.

Do Not rely solely on mechanical or hydraulic

jacks for support. Use adequate jack stands or

equivalent support.

2. With the rear of machine on jack stands and engine

running at full throttle, disengage the park brake

and move the speed control lever to the midway

position. Move the respective drive lever upward

until it reaches the neutral position and engage the

4