Voltage

Reading

Percent

Charge

Maximum

Charger

Settings

Charging

Interval

11.7–12.0

0–25%

14.4 volts/4

amps

3 Hours

11.7 or less

0%

14.4 volts/2

amps

6 Hours or

More

CAUTION

If the ignition is in the “ON” position there

is potential for sparks and engagement of

components. Sparks could cause an explosion or

moving parts could accidentally engage causing

personal injury.

Be sure ignition switch is in the “OFF” position

before charging the battery.

2. Connect the negative battery cable.

Note:

If the positive cable is also disconnected,

connect the

positive (red) cable

to the positive

battery terminal

first

, then the negative (black) cable

to the negative battery terminal. Slip insulator boot

over the positive terminal.

Note:

If time does not permit charging the battery,

or if charging equipment is not available, connect

the negative battery cable and run the vehicle

continuously for 20 to 30 minutes to sufficiently

charge the battery.

Checking Tire Pressure

1. Check the tire pressure in the drive tires. Proper

inflation for drive tires is 12-16 psi (83-110 kPa).

2. Adjust the tire pressure within 12-16 psi (83-110

kPa) range to make the tire circumferences match as

closely as possible.

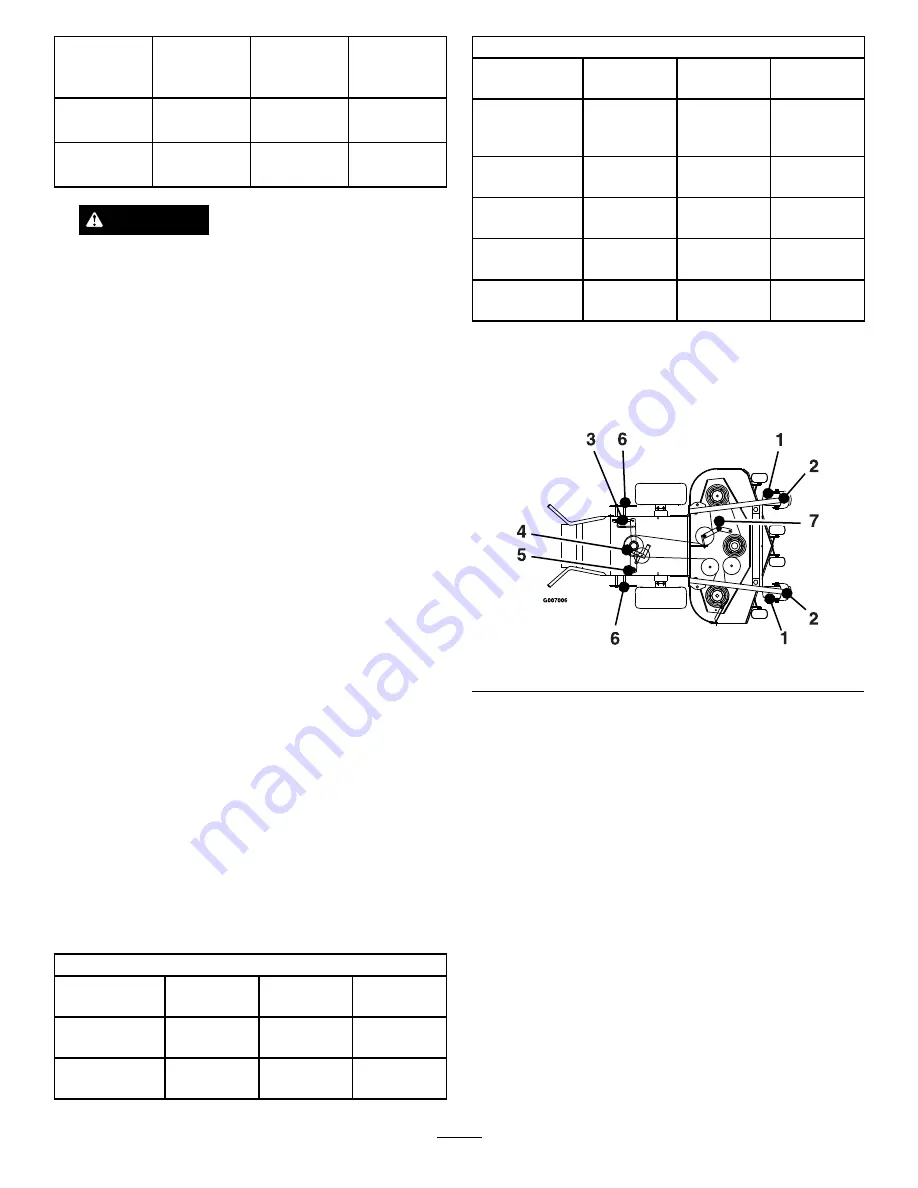

Greasing the Unit

Note:

The unit is not greased at the factory.

1. Lubricate fittings with NGLI grade #2

multi-purpose gun grease. Refer to the following

chart and Figure 8 for fitting locations and initial

pumps.

Lubrication Chart

Fitting

Locations

Initial

Pumps

Number of

Places

Service

Interval

1. Front Caster

Wheel Bearings

12

2

Daily

2. Front Caster

Pivots

2

2

Daily

Lubrication Chart

Fitting

Locations

Initial

Pumps

Number of

Places

Service

Interval

3.

PTO

Engagement

Bellcrank

1

1

40 hours

4. Pump Drive

Idler Pivot

2

1

Yearly

5. Clutch Arm

Pivot

1

1

40 hours

6. Pump Control

Bearings

2

2

40 hours

7. Mower Deck

Idler Pivots

2

1

Yearly

Number 4 (Pump Drive Idler Pivot) Located under

the engine deck.

Number 5 (Clutch Arm Pivot) Located under the

engine deck.

Figure 8

2. Lubricate the pivot point on PTO lever with a spray

penetrating lubricant.

Servicing the Engine

The engine is shipped with oil; check oil level and if

necessary fill to the appropriate level. Exmark 4-Cycle

Premium Engine Oil is recommended. Refer to the

Engine Owner’s Manual for an acceptable alternative.

Servicing the Hydraulic Oil

The machine is shipped with hydraulic oil in the

reservoir.

1. Run the machine for approximately 15 minutes to

allow any extra air to purge out of the hydraulic

system.

6