Maintenance

Periodic Maintenance

Check Engine Oil Level

Service Interval: Before each use or daily

1. Stop engine and wait for all moving parts to stop.

Make sure unit is on a level surface.

2. Check with engine cold.

3. Clean area around dipstick. Remove dipstick and

wipe oil off. Reinsert the dipstick and push it all

the way down into the tube.

Do Not

screw into

place. Remove the dipstick and read the oil level.

4. If the oil level is low, wipe off the area around the

oil fill cap, remove cap and fill to the “FULL”

mark on the dipstick. Exmark 4-Cycle Premium

Engine Oil is recommended; refer to the Engine

Owner’s manual for an acceptable alternative.

Do

Not

overfill.

Important:

Do Not operate the engine with the

oil level below the “LOW” (or “ADD”) mark on

the dipstick, or over the “FULL” mark.

Check Battery Charge

Service Interval: As required

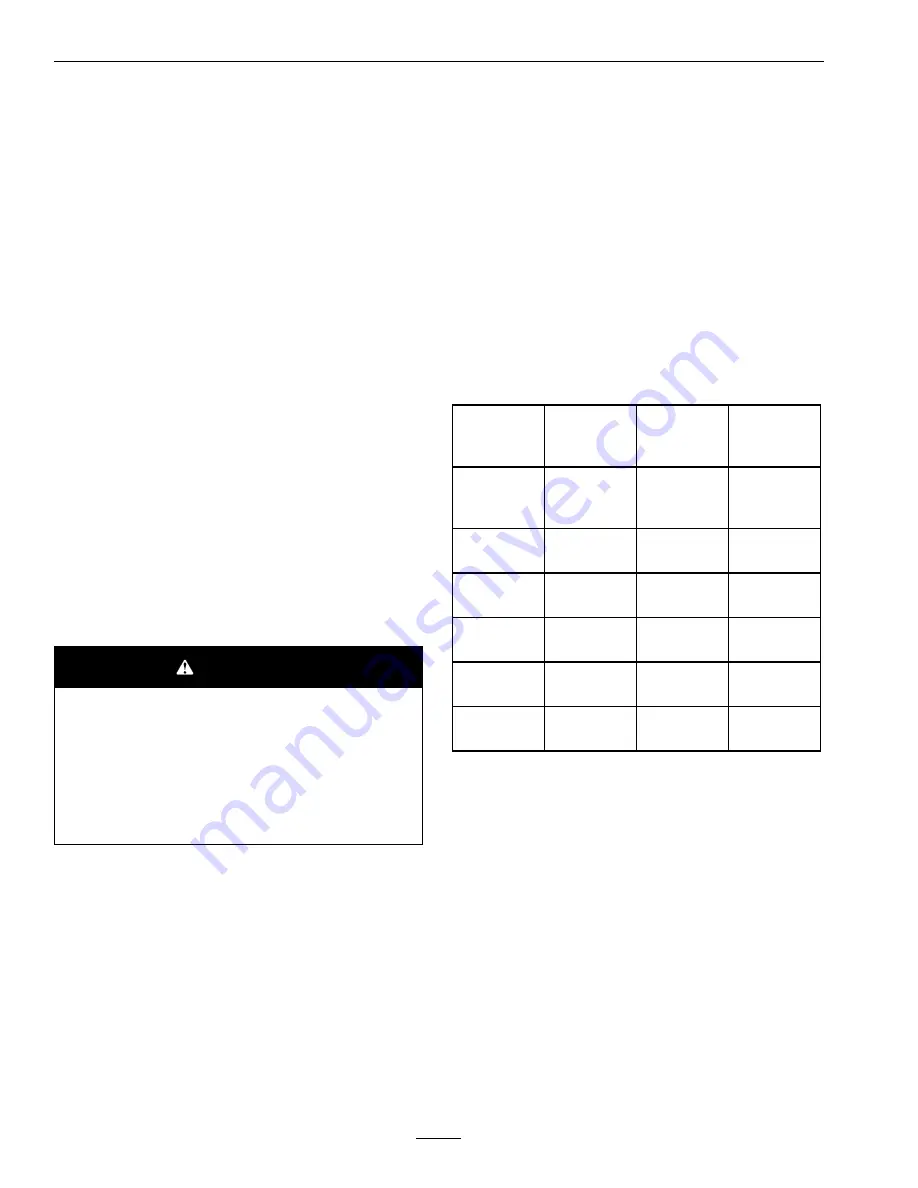

WARNING

CALIFORNIA

Proposition 65 Warning

Battery posts, terminals, and related

accessories contain lead and lead

compounds, chemicals known to the State of

California to cause cancer and reproductive

harm. Wash hands after handling.

Allowing batteries to stand for an extended period of

time without recharging them will result in reduced

performance and service life. To preserve optimum

battery performance and life, recharge batteries in

storage when the open circuit voltage drops to 12.4

volts.

Note:

To prevent damage due to freezing, battery

should be fully charged before putting away for

winter storage.

Check the voltage of the battery with a digital

voltmeter or with the message display. If the ignition

key is turned to the “on” position for a few seconds,

the battery voltage will be displayed in the area where

the hours are normally displayed. Locate the voltage

reading of the battery in the table and charge the

battery for the recommended time interval to bring

the charge up to a full charge of 12.6 volts or greater.

Important:

Make sure the negative battery cable

is disconnected and the battery charger used for

charging the battery should have an output of

16 volts and 7 amps or less to avoid damaging

the battery (see chart for recommended charger

settings). This is especially important on Kohler

EFI (Electronic Fuel Injection) units. Failure to

do so may damage the ECU (Electronic Control

Unit).

Voltage

Reading

Percent

Charge

Maximum

Charger

Settings

Charging

Interval

12.6 or

greater

100%

16 volts/7

amps

No

Charging

Required

12.4 – 12.6

75–100%

16 volts/7

amps

30 Minutes

12.2 – 12.4

50–75%

16 volts/7

amps

1 Hour

12.0–12.2

25–50%

14.4 volts/4

amps

2 Hours

11.7–12.0

0–25%

14.4 volts/4

amps

3 Hours

11.7 or less

0%

14.4 volts/2

amps

6 Hours or

More

Important:

For Kohler EFI units: Unplug the

harness from the ECU before performing any

welding on the equipment.

Recommended Jump

Starting Procedure

Service Interval: As required

1. Check the weak battery for terminal corrosion

(white, green, or blue “snow”), it must be cleaned

off prior to jump starting. Clean and tighten

connections as necessary.

24

Summary of Contents for TURF TRACER X-SERIES

Page 1: ...TURF TRACER X SERIES For Serial Nos 920 000 Higher Part No 4500 699 Rev A ...

Page 11: ...Safety 103 2242 103 2243 103 4935 103 2432 116 0404 11 ...

Page 12: ...Safety 116 4296 EFI Units Only 1 Fast 2 Slow 117 2718 12 ...

Page 38: ...Schematics Schematics Electrical Diagram All units except Kohler EFI 38 ...

Page 39: ...Schematics Electrical Diagram Kohler EFI 39 ...

Page 40: ...Schematics Electrical Logic Schematic All units except Kohler EFI 40 ...

Page 41: ...Schematics Electrical Logic Schematic Kohler EFI 41 ...

Page 42: ...Schematics Hydraulic Diagram 42 ...

Page 44: ...Notes 44 ...

Page 45: ...Service Record Date Description of Work Done Service Done By 45 ...

Page 46: ...46 ...