Maintenance

to neutral. Recheck the drive wheel rotation

to see if further adjustment is necessary.

4. The spring that keeps tension on the knob

should normally not need adjustment.

However, if adjustment is needed, adjust to

where length of spring is about 1 inch (2.5 cm)

between the washers. Adjust spring length by

turning nut at front of spring.

•

Drive Lever Linkage Adjustment:

1. With rear of machine still on jack stands and

engine running at full throttle, disengage

the park brake and move the speed control

lever to the midway position. Move the

respective drive lever upward until it reaches

the neutral position and engage neutral lock

latches (Figure 20). If the tire rotates in either

direction, the length of the drive lever link will

need to be adjusted.

Figure 20

2. Adjust the linkage length by loosening the jam

nuts at both ends of the linkage and rotating

the linkage in the ball joints. Lengthen the

linkage if the tire is turning in reverse and

shorten the linkage if the tire is creeping

forward. Tighten the jam nuts at both ends.

Release and re-engage the neutral lock latch

checking that the tire stops. Continue this

process until the tire is at a dead stop.

3. Make this adjustment for both sides.

4. Stop engine and wait for all moving parts

to stop. Raise rear of machine, remove jack

stands, and carefully lower machine to the

ground.

Tracking Adjustment

1. Stop engine and wait for all moving parts to stop.

2. Check the drive tire pressures and tire

circumferences as stated in

Check the Tire

Pressures

section in Maintenance.

3. Run the unit and observe the tracking on a level,

smooth, hard surface such as concrete or asphalt.

4. If the unit tracks to one side or the other, turn the

quick track knob. Turn the knob right to “steer”

right, turn the knob left to “steer” left.

Hydro Pump Spring Tension

Setting

1. For medium or heavy duty drive conditions such

as operation with a sulky on steep slopes, a higher

spring force may be required on the hydro pump

control arms to prevent the drive system from

stalling.

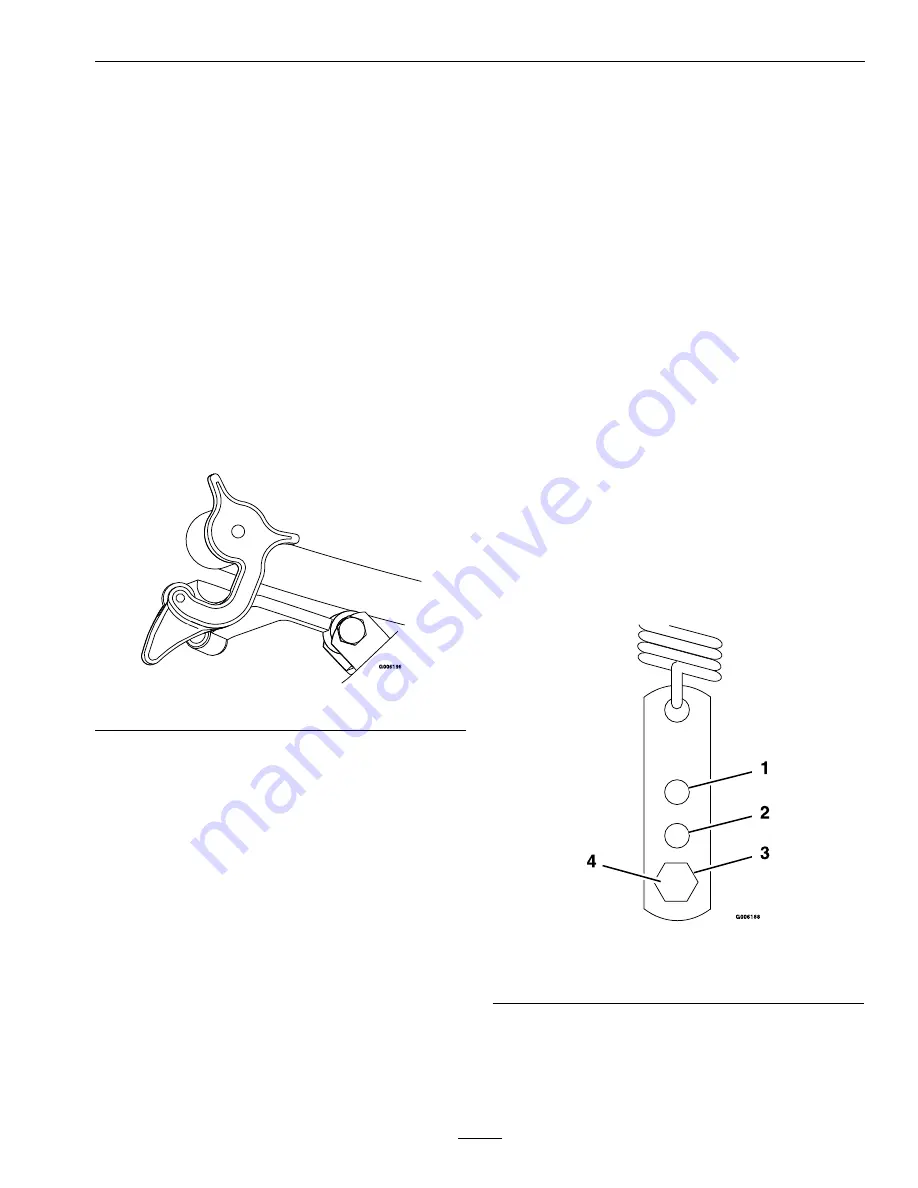

2. For a heavier drive setting, relocate the spring

anchor link as shown in Figure 13. The spring

anchor links are located under the engine deck on

the left and right hand sides.

Note:

In “medium” or “heavy duty” positions,

the drive lever forces at the upper handle will also

be increased.

Figure 21

1.

Heavy duty

3.

Standard

2.

Medium duty

4.

Retaining bolt

Electric Clutch Adjustment

No adjustment necessary.

35

Summary of Contents for TURF TRACER X-SERIES

Page 1: ...TURF TRACER X SERIES For Serial Nos 920 000 Higher Part No 4500 699 Rev A ...

Page 11: ...Safety 103 2242 103 2243 103 4935 103 2432 116 0404 11 ...

Page 12: ...Safety 116 4296 EFI Units Only 1 Fast 2 Slow 117 2718 12 ...

Page 38: ...Schematics Schematics Electrical Diagram All units except Kohler EFI 38 ...

Page 39: ...Schematics Electrical Diagram Kohler EFI 39 ...

Page 40: ...Schematics Electrical Logic Schematic All units except Kohler EFI 40 ...

Page 41: ...Schematics Electrical Logic Schematic Kohler EFI 41 ...

Page 42: ...Schematics Hydraulic Diagram 42 ...

Page 44: ...Notes 44 ...

Page 45: ...Service Record Date Description of Work Done Service Done By 45 ...

Page 46: ...46 ...