109-3195 Rev. C

Page 8 of 9

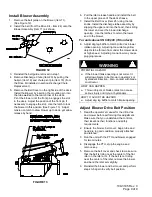

Align Dimple Here

3. Install the Rear Weight (Item 12) and spacer (Item

13) from the drive kit using the (8) 5/16 – 18

X1.75 screws (Item 14) and whizlock nuts

removed in step 1. Counter Weight Spacer (Item

13) should be placed between Rear Weight (Item

12) and Bagger Mount Weldment (Item 2).

All units

1. Slide tube ends of Hood Assembly (Item 4) into

the tubes of the mount weldment (Item 2). Install

(2) clevis pins (Item 16) through holes in tubes.

Retain with (2) Hair Pins (Item 17).

2. Hang the (2) Bag Assemblies (Item 5) from the

slots in the Bagger Upright (Item 4). Close and

latch hood.

Assemble Tubes

1. Slip upper and lower tubes together (Items 6

and 7).

2. Insert upper tube (Item 6) into hopper seal (Item

4) – push in then pull out so that seal is

extended outward.

3. Align dimple on upper tube (Item 6) with end of

hopper seal and position vertically between the

two screws (Item 4) as shown in Figure 10.

FIGURE 10

4.

Set deck in lowest cutting position.

5. Slide lower tube (Item 7) onto blower (Item 11)

and latch (make sure that upper tube does not

move out of alignment).

6. Drill 7/32 holes in lower tube (Item 7) using

upper tube (Item 6) holes as reference. See

Figure 11.

7. Remove tubes from unit and assemble the

upper (Item 6) and lower tubes (Item 7) using (3)

#10-24 x .75 hex washer head screws (Item 8),

(3) #10 washers (Item 9) , and (3) #10-24 nyloc

nuts (Item 10). Screw head should be installed

to the inside of the tube to provide minimum

obstruction to flow. Make sure that the upper

and lower ends are oriented properly as tubes

are assembled. (Parting lines roughly lined up.)

FIGURE 11

Drill holes here