10

WARNING:

When servicing, use only identical replacement parts.

Use of any other parts may create a hazard or cause

product damage.

WARNING:

Always wear safety goggles or safety glasses with side

shields during tool operation. If operation is dusty, also

wear a dust mask.

WARNING:

Before inspecting, cleaning, or servicing the machine,

shut off engine, wait for all moving parts to stop, and

disconnect spark plug wire and move it away from spark

plug. Failure to follow these instructions can result in

serious personal injury or property damage.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use. Use

clean cloths to remove dirt, dust, oil, grease, etc.

WARNING:

Do not at any time let brake fluids, gasoline, petroleum-

based products, penetrating oils, etc., come in contact

with plastic parts. Chemicals can damage, weaken or

destroy plastic which may result in serious personal

injury.

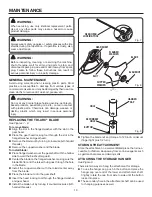

REPLACING THE TRI-ARC

®

BLADE

See Figures 7 - 8.

To remove blade:

Align the slot in the flanged washer with the slot in the

gear head.

Place the gear head locking tool through the slot in the

flanged washer and gear head.

Remove the blade nut by turning it clockwise (left-handed

threads).

Remove the cupped washer and the blade.

To install blade:

�

Place flanged washer over the gear shaft with the hollow

side toward the brushcutter guard.

�

Center the blade on the flanged washer, making sure the

blade fits flat and the raised hub goes through the hole

in the blade.

��

Install the cupped washer with the raised center away

from the blade.

��

Place the blade nut onto the gear shaft.

Insert the head locking tool through the flanged washer

and gear head.

��

Install the blade nut by turning it counterclockwise (left-

handed threads).

MAINTENANCE

Fig. 8

Fig. 9

BUTTON

HOLE

HANGER

CAP

SECONDARY

HOLE

Fig. 7

GEAR HEAD

LOCKING TOOL

BLADE NUT

CUPPED

WASHER

SLOT

FLANGED

WASHER

BLADE

GEAR SHAFT

��

Tighten the blade nut and torque to 120 in.lb. minimum

(finger tight plus 1/2 turn).

STORING THE ATTACHMENT

Store the attachment in a well-ventilated place that is inac-

cessible to children. Keep away from corrosive agents such

as garden chemicals and deicing salts.

ATTACHING THE STORAGE HANGER

See Figure 9.

There are two ways to hang the attachment for storage.

To use the hanger cap, push in the button and place the

hanger cap over end of the lower end attachment shaft.

Slightly rotate the cap from side to side until the button

locks into place.

The secondary hole in the attachment shaft can be used

for hanging purposes as well.

Summary of Contents for Expand-it UT15702B

Page 13: ...13 NOTES...