7

WARNING:

If any parts are damaged or missing, do not operate

this tool until the parts are replaced. Failure to heed this

warning could result in serious personal injury.

WARNING:

Do not attempt to modify this tool or create accesso-

ries not recommended for use with this tool. Any such

alteration or modification is misuse and could result in a

hazardous condition leading to possible serious personal

injury.

WARNING:

Do not connect to power head until assembly is complete.

Failure to comply could result in accidental starting and

possible serious personal injury.

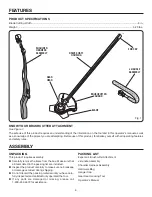

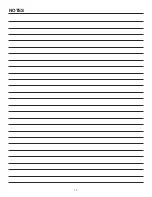

JOINING THE POWER HEAD TO THE

BRUSHCUTTER ATTACHMENT

See Figure 2.

WARNING:

Never attach or adjust any attachment while power head

is running. Failure to stop the engine may cause serious

personal injury.

The brushcutter attachment connects to the power head by

means of a coupler device.

Loosen the knob on the coupler of the power head shaft

and remove the end cap from the attachment shaft.

Push in the button located on the attachment shaft. Align

the button with the guide recess on the power head cou-

pler and slide the two shafts together. Rotate attachment

shaft until button locks into the positioning hole.

NOTE: If the button does not release completely in the

positioning hole, the shafts are not locked into place.

Slightly rotate from side to side until the button is locked

into place.

Tighten the knob securely.

WARNING:

Be certain the knob is fully tightened before operating

equipment. Check it periodically for tightness during use

to avoid serious injury.

REMOVING THE ATTACHMENT FROM THE

POWER HEAD

For removing or changing the attachment:

Loosen the knob.

Push in the button while twisting and pulling apart the

upper and lower sections.

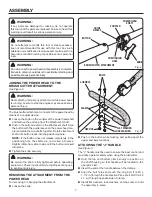

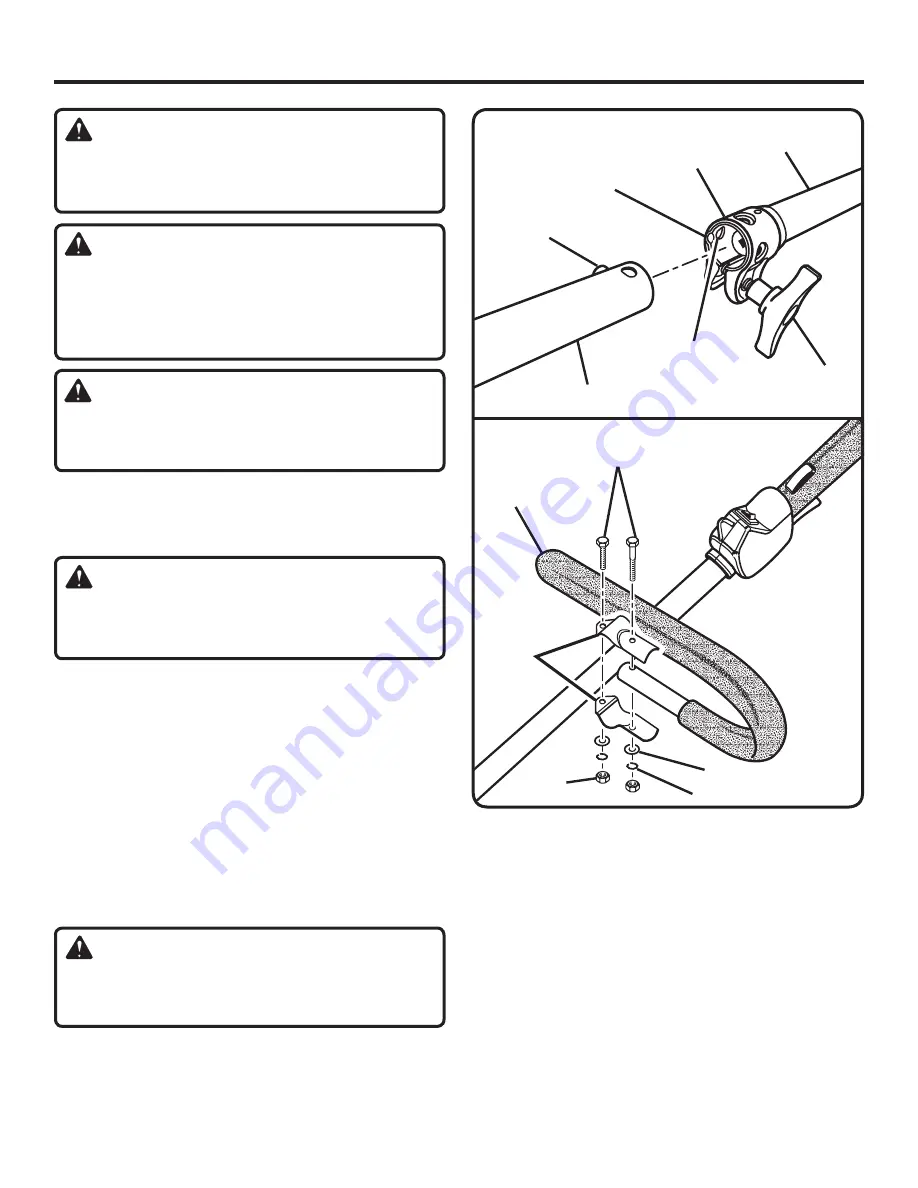

ATTACHING THE “J” HANDLE

See Figure 3.

The “J” handle must be used to ensure the best control and

maximize operator safety when using the brushcutter.

Hold the top and bottom clamp snugly in position on

the shaft housing so that handle will be located to the

operator’s left.

Insert the end of the handle between the clamps.

Align the bolt holes and push the long bolt (1/4-20 x

1-1/2 in.) through the handle side. Place short bolt (1/4-20

x 1 in.) through opposite side of clamp.

Install flat washers, lock washers, and hex nuts to hold

the assembly in place.

ASSEMBLY

Fig. 2

KNOB

COUPLER

BRUSHCUTTER ATTACHMENT

POWER HEAD

SHAFT

POSITIONING

HOLE

GUIDE

RECESS

BUTTON

Fig. 3

CLAMP

FLAT WASHER

LOCK WASHER

HEX NUT

J-HANDLE

BOLTS

Summary of Contents for Expand-it UT15702B

Page 13: ...13 NOTES...