CARAT

43

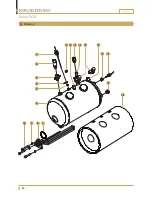

EXPLODED VIEW

Machine with 1GR

Spare parts list

POS.

PCS

Part No.

Description

1

1

1264089

Left panel upper white

2

1

1264162

Left panel upper black

3

1

1264090

Left panel lower white

4

1

1264163

Left panel lower black

5

1

260712

Left Upper Panel Cover

6

1

1264096

Display overlay 1Gr TS

7

1

1264141

Display overlay 1Gr Standard

8

1

260688

Display Panel 1Gr Standard

9

1

260711

Display Panel Assy 1GR Carat

10

1

260718

Back Panel 1GR Carat

11

1

260715

Right Lower Panel Cover

12

1

260714

Right Upper Panel Cover

13

1

260713

Left Lower Panel Cover

14

1

260720

Group Cover Support Carat

15

1

260674

Cup Holder Carat

16

1

1264104

Front Brand Panel

17

1

1264167

Front brand panel 1Gr black

18

1

260716

Drip Tray 1GR Carat

19

1

260717

Grid Carat 1Gr

20

1

260710

Front Panel 1GR Carat

21

1

1264092

Right panel lower white

22

1

1264165

Right panel lower black

23

1

1264091

Right panel upper white

24

1

1264164

Right panel upper black

25

1

260719

Top Cup Tray 1GR Carat

26

1

260679

Strengthen Panel 1Gr

27

1

260677

Water Proof Top

28

1

1260005

Insulation Back Panel Carat 1Gr

29

1

1260015

Insulation Top Tray 1Gr

30

1

1264208

Back Overlay 1Gr

31

1

1264241

Water Proof Pan 1Gr

32

2

1264234

Plactic Strip

33

2

260676

Bearing

34

1

C10200141

Pole thermal cut-out with bulb

35

1

1608281

Magnet 39x13x6

Summary of Contents for CARAT 1GR

Page 1: ...CARAT TECHNICAL MANUAL TM_EN Part No 1764016_01 Date 150413 ...

Page 40: ...CARAT 40 WATER SYSTEM Machine with 1GR Cold water Hot water Drain waste water ...

Page 41: ...CARAT 41 WATER SYSTEM Machine with 2GR Cold water Hot water Drain waste water ...

Page 46: ...CARAT 46 6 EXPLODEDVIEW Rotary pump Drawing 2 3 9 7 8 4 1 5 10 11 ...

Page 48: ...CARAT 48 EXPLODEDVIEW Boiler 1GR Drawing 1 11 12 13 14 7 8 16 17 18 9 6 4 5 5 3 2 10 15 ...

Page 50: ...CARAT 50 EXPLODEDVIEW Boiler 2GR Drawing 13 15 14 14 16 11 3 4 6 7 5 8 9 10 12 1 2 17 18 12 ...

Page 59: ...CARAT 59 EXPLODEDVIEW Hot water outlet Drawing 1 2 3 4 5 6 7 11 12 8 9 10 ...

Page 61: ...CARAT 61 EXPLODEDVIEW Group head Drawing 1 7 15 14 13 2 8 3 9 4 16 11 5 12 6 10 ...

Page 63: ...CARAT 63 EXPLODEDVIEW Lower water system Drawing 6 7 8 9 10 11 12 3 4 2 13 5 1 ...