35

CARNES STEAM MANIFOLDS with strong galvanized flanged frames are factory

assembled to reduce installation costs.

LOCATION OF MANIFOLD

The manifold is usually located in the supply duct downstream of

the fan, heating coil, cooling coil, and/or filter. When installed in

packaged units, the manifold is to be mounted just downstream of

the fan discharge.

The non-wetting dimension is the distance necessary to prevent

condensation on any obstruction downstream from the manifold.

Condensation could occur on a cooling coil because of lower

temperatures. Steam plumes may be visible beyond the

non-wetting dimension and may moisten high efficiency filters.

Additional distance is required for installation upstream of high

efficiency filters.

Carnes humidifiers operate at 1/2 psi or less so there are

limitations on the length between the humidifier cabinet and the

steam manifold. The maximum distance depends on the static

pressure in the duct and is shown in

Table 6

.

MAXIMUM STEAM HOSE LENGTH

(Table 6)

Duct Static

0 1 2 3 4 5

Pressure

“wg”

Maximum Steam

40 35 30 25 15 10

Hose Length (Ft.)

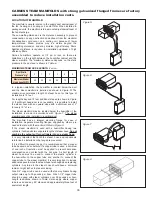

In a typical installation, the humidifier is located below the duct

and the steam manifold is installed as shown in

Figure R

. The

maximum recommended length of steam hose for this type of

installation is 12 feet.

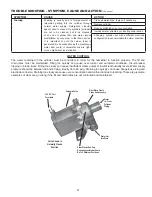

For lengths beyond 12 feet additional steps are shown in

Figure

S

. If sufficient headroom is not available, it is possible to install

the steam hose with an upward slope with a minimum rise of 2”

for every 12” of run.

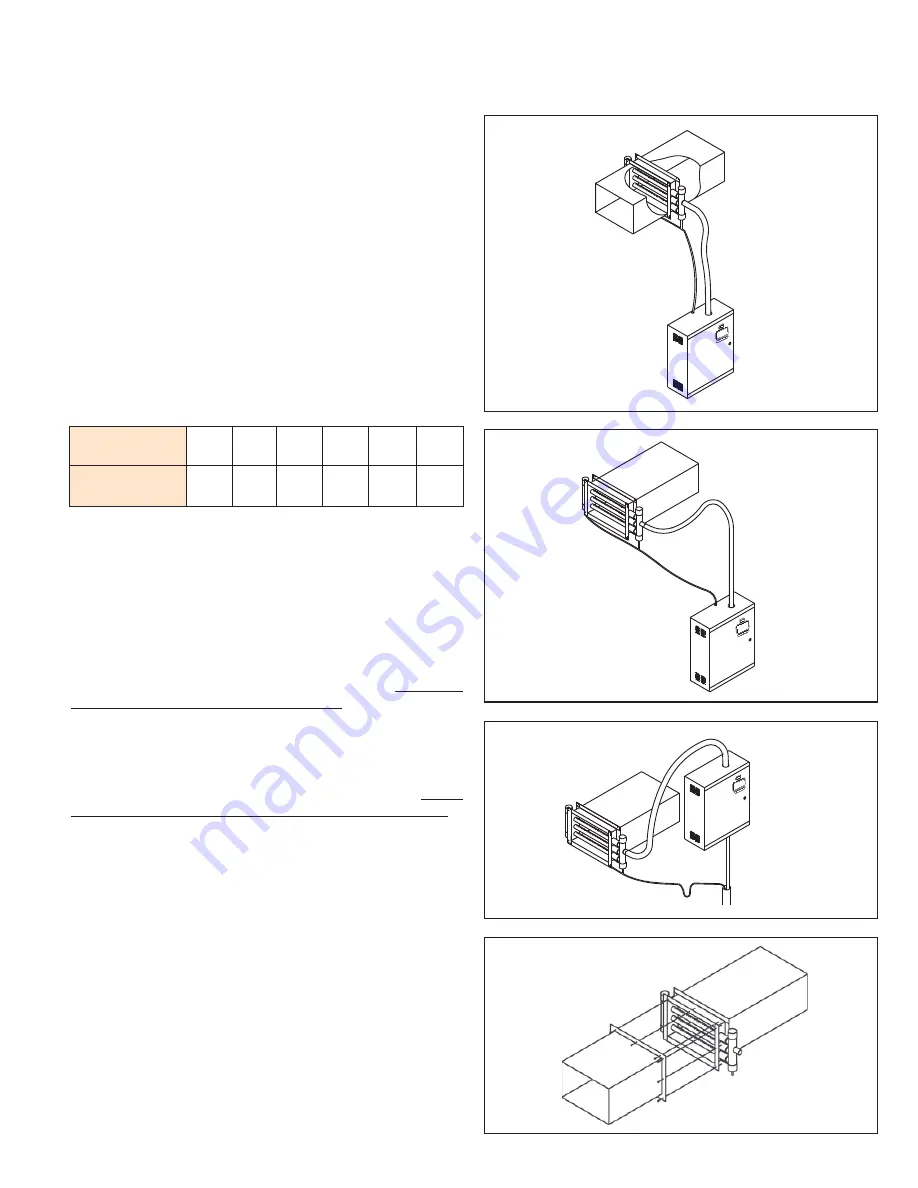

The steam manifold may be located below the humidifier if the

installation is made in accordance with

Figure T

. The steam

manifold cannot be installed in a vertical duct.

The manifold has an integral mounting flange for ease of

installation. Separate mounting flanges, supplied by others, are

needed to mate with the manifold.

Refer to Figure U

.

If the steam manifold is used with a humidifier having two

cylinders it will require two separate lengths of steam hose.

Do not

combine the outputs of two cylinders into one steam hose.

It is very important that both the steam hose and condensate

return line be installed so that sags are prevented.

If it is difficult to prevent sags, it is recommended that a copper

tube be used as a substitute. If a copper tube is used, a minimum

of one inch of insulation must be applied to prevent excessive

condensation and contact with the hot pipe. A short length of

steam hose must be used to connect the plastic cylinder in

the humidifier to the copper tube and another to connect the

copper tube to the steam manifold. It is very important to include

adequate space to move the steam hose far enough when replacing

cylinders. Any turns in the steam hose should have a minimum

radius of eight inches to prevent kinking.

Size 3/4” copper tube can be used with steam cylinders having

output rates up to 30 pounds per hour. Size 1-1/2” copper tube

should be used with steam cylinders over 30 pounds per hour.

Length restrictions shown in

Table 6

also apply where copper

tube is used and any 90° elbows add approximately three feet of

equivalent length.

Figure R

Figure S

Figure T

Figure U