C-12 CRUSHER

JAW BRAKE PRESSURE ADJUSTMENT

The following proceedures are carried out with the machine running so extra care

MUST

be taken to ensure

the saftey of

ANY

personnel on or in the vicinity of the machine.

1)

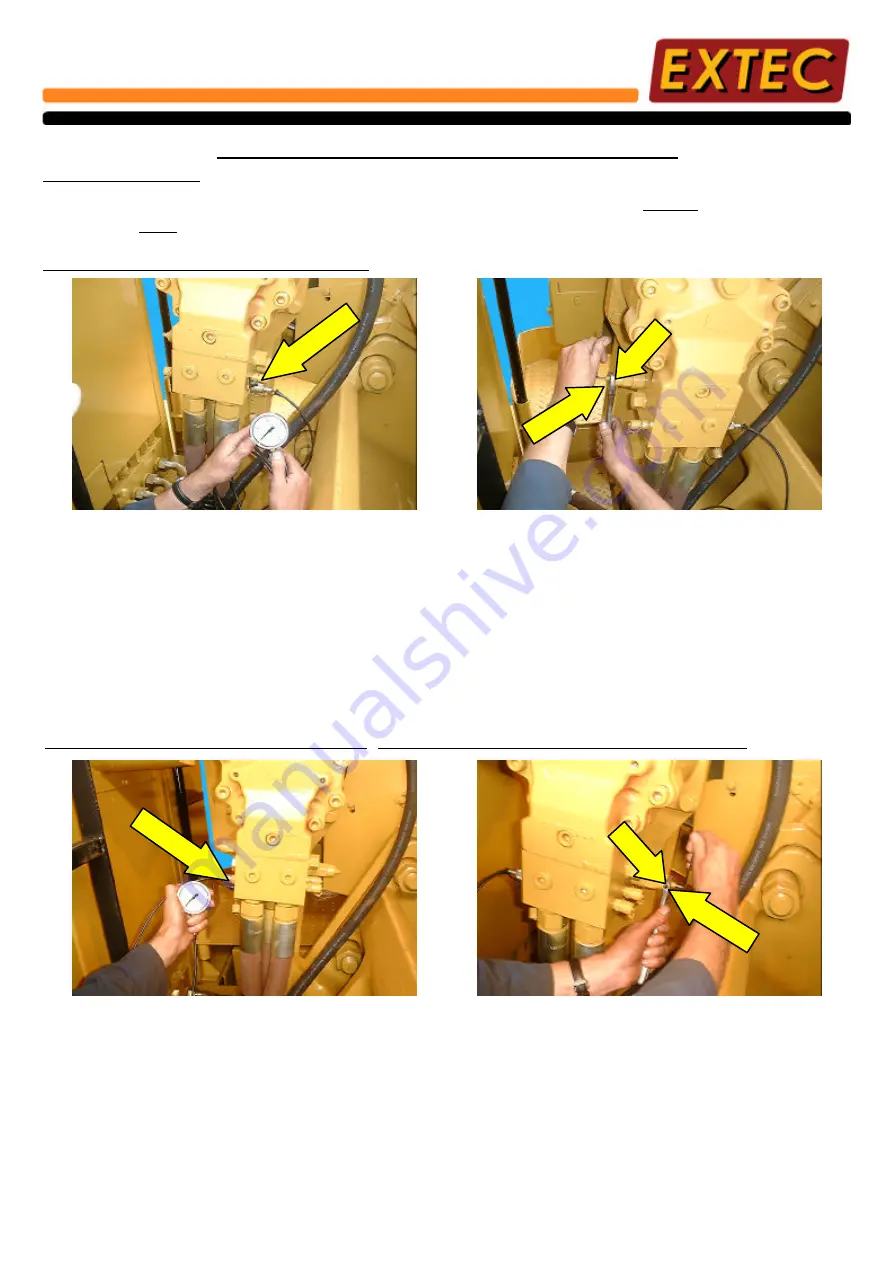

Attach pressure gauge to pressure point as shown.

2)

Start crusher on speed on No 2 then stop crusher (pressure gauge should read 250 bar). If required adjust

pressure using following procedure.

3)

Unscrew lock nut on relief valve grub screw. (To reduce pressure turn the screw anti-clockwise, to increase

pressure turn the screw clockwise.) Turn screw about ¼ of a turn.

4)

Repeat procedures 2 & 3 checking pressure each time.

5)

When the pressure reads 250 bar lock the screw in position with the attached lock nut.

6)

The jaw will run for approximately 5 seconds when stopping.

SAFETY NOTICE

FORWARD JAW BRAKE PRESSURE

REVERSE JAW BRAKE PRESSURE-

(Note: jaw should only be run in reverse on speed No.1

1)

Attach pressure gauge to pressure point as shown.

2)

Start crusher in reverse jaw on speed on No 1 then stop crusher (pressure gauge should read 350 bar). If

required adjust pressure using following procedure.

3)

Unscrew lock nut on relief valve grub screw. (To reduce pressure turn the screw anti-clockwise, to increase

pressure turn the screw clockwise.) Turn screw about ¼ of a turn.

4)

Repeat procedures 2 & 3 checking pressure each time.

5)

When the pressure reads 350 bar lock the screw in position with the attached locknut.

6)

The jaw will run for approximately 2 seconds when stopping.

Pressure Point

Pressure Point

Grub screw

Lock Nut

Grub screw

Lock Nut

25