Ver: IC13-EN-10567

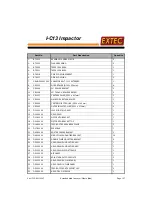

Side Conveyor

Page 133

I-C13 Impactor

Part No.

Part Description

Quantity

1.

BT1009

PLUMBER BLOCK BEARING

2

2.

BT2009

FLANGE BEARING

2

3.

BT5005

TAPER LOCK

1

4.

BT5006

TAPER LOCK

1

5.

BT6514

DRIVE COUPLING INSERT

1

6.

BT6515

DRIVE COUPLING INCLUDES

1

7.

CB69250700CH

ENDLESS CHEVRON BELT

1

8.

CR1006

40° ROLLER BRACKET

2

9.

CR1013

SIDE WING ROLLER

8

10.

CR1016

CENTRE ROLLER

4

11.

CR1028

RETURN ROLLER

2

12.

CR1031

SLAPPER ROLLER

1

13.

D4910000

MOUNTING BRACKET

3

14.

E0070000

DRIVE DRUM

1

15.

E0080000

END DRUM

1

16.

E0150000

BEARING SLIDER

2

17.

E0240000

MOUNTING BRACKET COVER

1

18.

E1030000

TAIL DRUM SCRAPER

1

19.

E1070000

FEED BOOT CLAMP

2

20.

E1090000

FEED BOOT CLAMP

1

21.

E1130000

END DRUM GUARD

1

22.

E1440000

MOTOR MOUNTING

1

23.

E1500000

SIDE CONVEYOR BOTTOM SECTION

1

24.

E1510000

SIDE CONVEYOR TOP SECTION

1

25.

E1520000

FOLD RAM - TOP MOUNTING BRACKET

1

26.

E1530000

FOLD RAM - BOTTOM MOUNTING BRACKET

1

27.

E1540000

MOUNTING BRACKET

1

28.

E1550000

MOUNTING BRACKET

1

29.

E1560000

MOUNTING BRACKET

1

30.

E1570000

MOUNTING BRACKET

1

31.

E1860000

MOUNTING BRACKET COVER

1

32.

E1890000

CONVEYOR FLARE

1

Summary of Contents for I-C13 Impactor

Page 10: ...Page x Contents Ver IC13 EN 10567 I C13 Impactor...

Page 13: ...Ver IC13 EN 10567 Safety Instructions Page 3 I C13 Impactor...

Page 14: ...Page 4 Safety Instructions Ver IC13 EN 10567 I C13 Impactor...

Page 26: ...Page 16 Safety Instructions Ver IC13 EN 10567 I C13 Impactor Intentionally left blank...

Page 34: ......

Page 80: ...Page 70 Trouble Shooting Guide Ver IC13 EN 10567 I C13 Impactor Intentionally left blank...

Page 185: ...Ver IC13 EN 10567 Stickers English Page 175 I C13 Impactor 11 12 13 14 15 16 17 18...

Page 186: ...Page 176 Stickers English Ver IC13 EN 10567 I C13 Impactor 19 20 21 22 23 24 25 26 27 28...

Page 187: ...Ver IC13 EN 10567 Stickers English Page 177 I C13 Impactor 29 30 31 32 33 34 35 36...

Page 195: ...Ver IC13 EN 10567 Water Pump Optional Page 185 I C13 Impactor Intentionally left blank...

Page 196: ...Page 186 Water Pump Optional Ver IC13 EN 10567 I C13 Impactor...

Page 198: ...Page 188 Ver IC13 EN 10567 I C13 Impactor Figure B 1 CONTROL CONNECTOR...

Page 199: ...Ver IC13 EN 10567 Page 189 I C13 Impactor Figure B 2 CONTROLLER CONNECTOR...

Page 200: ...Page 190 Ver IC13 EN 10567 I C13 Impactor Figure B 3 ENGINE SCHEMATIC...

Page 201: ...Ver IC13 EN 10567 Page 191 I C13 Impactor Figure B 4 RECEIVER AND LOOM...

Page 202: ...Page 192 Ver IC13 EN 10567 I C13 Impactor Figure B 5 SOLENOID CONTROL PANEL...

Page 203: ...Ver IC13 EN 10567 Page 193 I C13 Impactor Figure B 6 ELECTRONIC PANEL...

Page 204: ...Page 194 Ver IC13 EN 10567 I C13 Impactor Figure B 7 AUXILARY LOOMS...

Page 206: ...Page 196 Ver IC13 EN 10567 I C13 Impactor Figure B 9 RECIRC REL TRACK VALVE LOOM...

Page 208: ...Ver IC13 EN 10134 Page 198 I C13 Impactor Intentionally left blank...

Page 210: ...Page 200 Ver IC13 EN 10567 I C13 Impactor Intentionally left blank...

Page 218: ...Page 210 Ver IC13 EN 10567 I C13 Impactor Intentionally left blank...

Page 219: ...Ver IC13 EN 10567 Page 211 I C13 Impactor...

Page 220: ...Page 212 Ver IC13 EN 10567 I C13 Impactor...

Page 221: ...Ver IC13 EN 10567 Page 213 I C13 Impactor...

Page 222: ...Page 214 Ver IC13 EN 10567 I C13 Impactor...

Page 223: ...Ver IC13 EN 10567 Page 215 I C13 Impactor...

Page 224: ...Page 216 Ver IC13 EN 10567 I C13 Impactor...

Page 225: ...Ver IC13 EN 10567 Page 217 I C13 Impactor...

Page 226: ...Page 218 Ver IC13 EN 10567 I C13 Impactor...

Page 227: ...Ver IC13 EN 10567 Page 219 I C13 Impactor...

Page 228: ...Page 220 Ver IC13 EN 10567 I C13 Impactor...

Page 229: ...Ver IC13 EN 10567 Page 221 I C13 Impactor...

Page 230: ...Page 222 Ver IC13 EN 10567 I C13 Impactor...

Page 231: ...Ver IC13 EN 10567 Page 223 I C13 Impactor...

Page 232: ...Page 224 Ver IC13 EN 10567 I C13 Impactor...

Page 233: ...Ver IC13 EN 10567 Page 225 I C13 Impactor...

Page 234: ...Page 226 Ver IC13 EN 10567 I C13 Impactor...

Page 235: ...Ver IC13 EN 10567 Page 227 I C13 Impactor...

Page 236: ...Page 228 Ver IC13 EN 10567 I C13 Impactor...

Page 237: ...Ver IC13 EN 10567 Page 229 I C13 Impactor...

Page 238: ...Page 230 Ver IC13 EN 10567 I C13 Impactor...

Page 239: ...Ver IC13 EN 10567 Page 231 I C13 Impactor...

Page 240: ...Page 232 Ver IC13 EN 10567 I C13 Impactor...

Page 241: ...Ver IC13 EN 10567 Page 233 I C13 Impactor...

Page 242: ...Page 234 Ver IC13 EN 10567 I C13 Impactor...

Page 243: ...Ver IC13 EN 10567 Page 235 I C13 Impactor...

Page 244: ...Page 236 Ver IC13 EN 10567 I C13 Impactor...

Page 245: ...Ver IC13 EN 10567 Page 237 I C13 Impactor...

Page 246: ...Page 238 Ver IC13 EN 10567 I C13 Impactor...

Page 247: ...Ver IC13 EN 10567 Page 239 I C13 Impactor...

Page 248: ...Page 240 Ver IC13 EN 10567 I C13 Impactor...

Page 249: ...Ver IC13 EN 10567 Page 241 I C13 Impactor...

Page 250: ...Page 242 Ver IC13 EN 10567 I C13 Impactor...

Page 251: ...Ver IC13 EN 10567 Page 243 I C13 Impactor...

Page 252: ...Page 244 Ver IC13 EN 10567 I C13 Impactor...

Page 253: ...Ver IC13 EN 10567 Page 245 I C13 Impactor...

Page 254: ...Page 246 Ver IC13 EN 10567 I C13 Impactor...

Page 255: ...Ver IC13 EN 10567 Page 247 I C13 Impactor...

Page 256: ...Page 248 Ver IC13 EN 10567 I C13 Impactor...

Page 257: ...Ver IC13 EN 10567 Page 249 I C13 Impactor...

Page 258: ...Page 250 Ver IC13 EN 10567 I C13 Impactor...

Page 259: ...Ver IC13 EN 10567 Page 251 I C13 Impactor...

Page 260: ...Page 252 Ver IC13 EN 10567 I C13 Impactor...

Page 261: ...Ver IC13 EN 10567 Page 253 I C13 Impactor...

Page 262: ...Page 254 Ver IC13 EN 10567 I C13 Impactor...

Page 263: ...Ver IC13 EN 10567 Page 255 I C13 Impactor...

Page 264: ...Page 256 Ver IC13 EN 10567 I C13 Impactor...

Page 265: ...Ver IC13 EN 10567 Page 257 I C13 Impactor...

Page 266: ...Page 258 Ver IC13 EN 10567 I C13 Impactor...

Page 267: ...Ver IC13 EN 10567 Page 259 I C13 Impactor...

Page 268: ...Page 260 Ver IC13 EN 10567 I C13 Impactor...

Page 269: ...Ver IC13 EN 10567 Page 261 I C13 Impactor...

Page 270: ...Page 262 Ver IC13 EN 10567 I C13 Impactor...

Page 271: ...Ver IC13 EN 10567 Page 263 I C13 Impactor...

Page 272: ...Page 264 Ver IC13 EN 10567 I C13 Impactor...

Page 273: ...Ver IC13 EN 10567 Page 265 I C13 Impactor...

Page 274: ...Page 266 Ver IC13 EN 10567 I C13 Impactor...

Page 275: ...Ver IC13 EN 10567 Page 267 I C13 Impactor...

Page 276: ...Page 268 Ver IC13 EN 10567 I C13 Impactor...

Page 277: ...Ver IC13 EN 10567 Page 269 I C13 Impactor...

Page 278: ...Page 270 Ver IC13 EN 10567 I C13 Impactor...

Page 279: ...Ver IC13 EN 10567 Page 271 I C13 Impactor...

Page 280: ...Page 272 Ver IC13 EN 10567 I C13 Impactor...

Page 281: ...Ver IC13 EN 10567 Page 273 I C13 Impactor...

Page 282: ...Page 274 Ver IC13 EN 10567 I C13 Impactor...

Page 283: ...Ver IC13 EN 10567 Page 275 I C13 Impactor...

Page 284: ...Page 276 Ver IC13 EN 10567 I C13 Impactor...

Page 285: ...Ver IC13 EN 10567 Page 277 I C13 Impactor...

Page 286: ...Page 278 Ver IC13 EN 10567 I C13 Impactor...

Page 287: ...Ver IC13 EN 10567 Page 279 I C13 Impactor...

Page 288: ...Page 280 Ver IC13 EN 10567 I C13 Impactor...

Page 289: ...Ver IC13 EN 10567 Page 281 I C13 Impactor...

Page 290: ...Page 282 Ver IC13 EN 10567 I C13 Impactor...

Page 292: ...Page 284 Ver IC13 EN 10567 I C13 Impactor Intentionally left blank...