13

Chapter 11 Adjustment

Warning: Before adjusting portion of the machine. Cut the power first, and make

adjustments after receiving instructions.

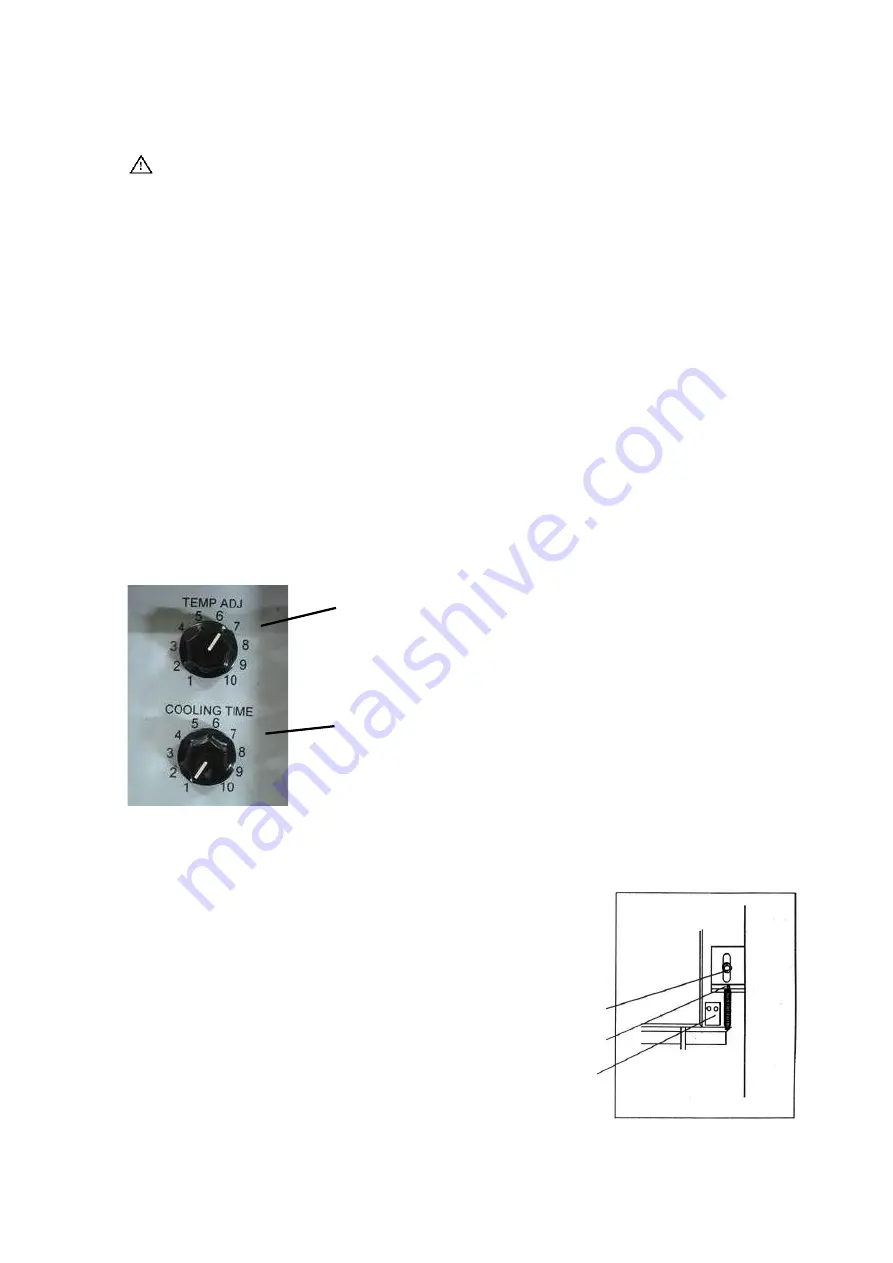

11-1 Adjustment of Heater Temperature

Turn the heater temperature knob to the right to increase the temperature and to the left

to reduce the temperature.

Depending on the type and size of the strap, the heater temperature may need to be

adjusted, (in common currency, the scale is 5-7) if the temperature is too short, the

strap can not be welded; contrarily, the strap will be welded over and break, (Please

refer to the diagram on the right)

11-2 Adjustment of cooling Timer

This timer is to adjust the press cooling time for the strap-welding portion. The time is

set long by turning this knob clockwise and set short by turning counterclockwise. The

range of the time is 0-0.4sec; the standard setting is in the scale 4(0.15sec.). If the time

is too short, the strap will break when the tension is bigger

11-3 Adjustment of Strap-collected Length in the Pool

This is to adjust the length of the strap

Collected in the pool with the prefeed

Roller. The length gets long when loosening

The bolt and moving the spring hook upward.

The arch. If the length is too long, not only the strap

Will not be feeded/turned back smoothly. But also

The strap will be distortion; If the length is too short,

One packing circle cannot be finished.

B

o

lt

Sp

rin

g

hook

Sw

itc

h

TEMP ADJ

COOLING TIME