4

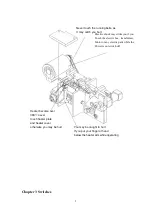

TEMP. ADJUSTMENT

COOLING TIME

AUTO/MANUAL SWITCH

Symbol Name

Function

Power Switch

The machine gets on by revolve the switch clockwise

And the power lamp starts blinking. When the warming

By the heater complete, the lamp become glowing to

Show that the operation is ready,(in approx.20 seconds).

When the switch is revolved anti-clockwise the machine

get OFF

Start Button

This switch has 3roles.

To set new strap

To start strapping.

To return the cam shaft to the origin and set strap in the

arch.

Strap back switch

Use this switch to keep this switch ON until the strap is

back

Little or is out of the machine

Caution:

Exhausted strap shall be manually rewound to

The coil or cut and throw away before retread it.

Otherwise, loose strap may be intertwined

Tension dial

To adjust tightening stroke,

Strap is tightened strong by turning right.

Strap is loosened strong by turning left.

Stop switch

The machine stop strapping when press the button

Power lamp

To show that the machine get on