22

4.

OPERATING THE MACHINE

a.

Turn main switch QS1 to ON. The heating element reaches the working temperature at

approximately 1 minute.

b.

Place a package on the table top (The package must cover the Slide Table).

c.

Properly adjust the strap tension knob according to various packages.

d.

Place the strap around the package to be strapped and insert the strap into the trapping

head to activate micro-switch until strapping cycle stops.

e.

The strapping and welding sequence should complete.

f.

At end of strapping sequence the strap end is fed automatically, and Feed length

adjustment knob is to adjust the strap length

g.

Adjustment

JOG:

This JOG function is for service only, it could make machine go step by step. In any

position, you could press RESET button back to ready position

COOLING TIME:

Cooling time is for big tension strap on hard package to have longer cooling time

after strap is hot sealed.

TEMP.

This adjust VR is for heater plate temperature. Depend on PP strap or working

environment, you might need to adjust this heater plate temperature for better

sealing on straps. The default setting will be around 290 Celsius degree for

polypropylene straps.

JOG

COOLING TIME

TEMP.

Summary of Contents for EXS-303

Page 1: ...1 SEMI AUTOMATIC STRAPPING MACHINE MODEL EXS 303 OPERATION MANUAL 2019 08 19...

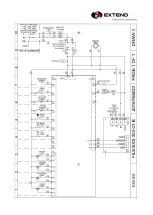

Page 28: ...28 8 ELECTRIC WIRING DIAGRAM PART...

Page 29: ...29...

Page 30: ...30...

Page 32: ...32...

Page 33: ...33 9 PART LIST...

Page 34: ...34 FIG 1 1 SEALER SEAT UNIT...

Page 37: ...37 FIG 2 1 FEED DRIVE UNIT...

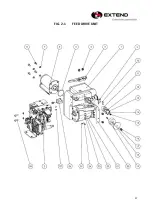

Page 44: ...44 FIG 8 1 SEPARATING PLATE UNIT...

Page 46: ...46 FIG 9 1 HEATER PLATE UNIT...

Page 48: ...48 FIG 10 1 BODY FRAME...

Page 51: ...51 FIG 11 1 DISPENSER ASSEM...

Page 53: ...53 FIG 12 1 DISPENSER UNIT...